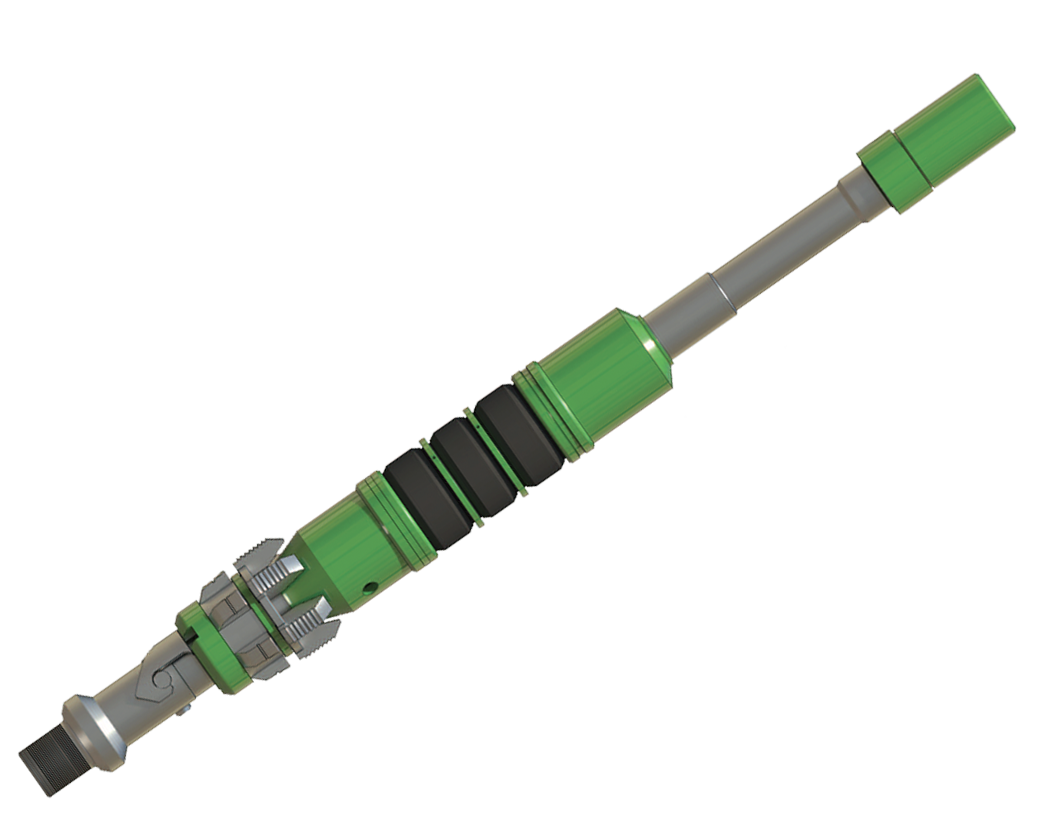

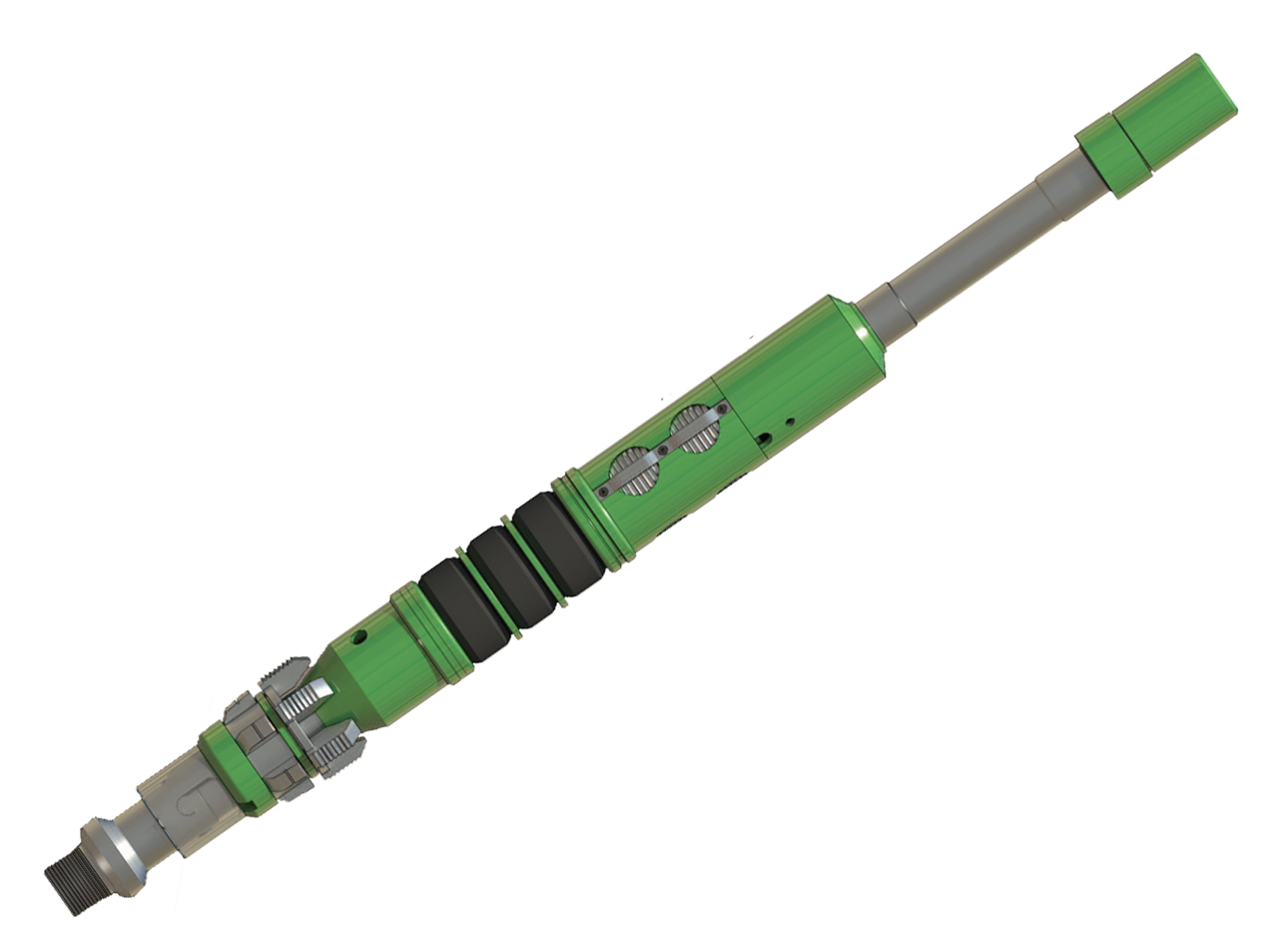

Tubing Hanger Coupling - 4 ½” to 2 7/8”

Tubing Hanger Coupling

Also known as:

Tubing Coupling, Tubing Hanger Adapter

Tubing Hanger Coupling - 4 ½” to 2 7/8”

Tubing Hanger Coupling

Also known as:

Tubing Coupling, Tubing Hanger AdapterBuy

Made to Order

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

4 - 6 WeeksNote:

The 4 ½ x 2 7/8” Tubing Hanger Coupling enables a strong transition between mid- to large-size tubing, offering increased flow capacity while maintaining compact installation with upset ends.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The 4 ½ x 2 7/8” Tubing Hanger Coupling is built for applications where a high-strength connection is needed between larger bore tubing and a robust production string. This size pairing is often selected to balance flow capacity with structural integrity, especially in completions requiring higher volume production without compromising pressure control.

The coupling’s upset-end compatibility enhances joint strength, while its threaded, union-nut assembly allows for secure installation without disturbing surface equipment. Designed to meet API standards and accommodate back pressure valves, this coupling offers dependable performance in variable well conditions and supports operators in optimizing flow efficiency and tubing stability.

Technical Specifications

| Tubing Size (Top) | 4 ½” |

| Tubing Size (Bottom) | 2 7/8” |

| Standard | API |

| Tubing Type | Upset Tubing |

| Installation | Union nut, no Xmas tree rotation |

| Threading | Customizable top & bottom threads |

| Features | Threaded for back pressure valve |

| Usage | Works with tubing hanger spools |

| Material | Alloy steel |

| Compatibility | Fits standard tubing hanger systems |

Features and Benefits

- Union nut design for easy installation without rotating the Christmas tree.

- Supports moderate to high production volumes with reliable mechanical strength.

- Connects 4 ½” and 2 7/8” upset tubing.

- Constructed from high-grade, corrosion-resistant steel.

- Enables secure transition between tubing sizes while maintaining flow efficiency.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The 4 ½ x 2 7/8” Tubing Hanger Coupling is a specialized connection component used in oil and gas wellhead systems to join two different sizes of upset tubing—4 ½-inch and 2 7/8-inch. This size combination is commonly selected when there is a need to transition from a wider tubing hanger profile to a smaller production string, without significantly restricting flow or compromising mechanical strength. The slightly larger 2 7/8” production tubing allows for greater internal flow area than smaller alternatives, making this configuration well-suited for completions that aim to support moderate to high production rates.

The coupling is designed with a union nut mechanism, which enables installation without rotating the Christmas tree or disturbing other surface equipment. This simplifies operations, especially in space-limited or sensitive surface environments. Both the top and bottom threads of the coupling can be manufactured to meet specific customer requirements, ensuring compatibility with a range of tubing string designs. Additionally, the coupling is threaded to accommodate a back pressure valve, offering an important safety feature by allowing well pressure to be managed during maintenance or pressure control procedures.

Constructed from high-grade steel and compliant with API standards, the 4 ½ x 2 7/8” Tubing Hanger Coupling offers high durability, corrosion resistance, and the mechanical integrity required for challenging downhole conditions. By supporting a secure, pressure-tight connection between tubing sizes, it plays a key role in maintaining well integrity and operational efficiency in various oil and gas production scenarios.

Engineering Data