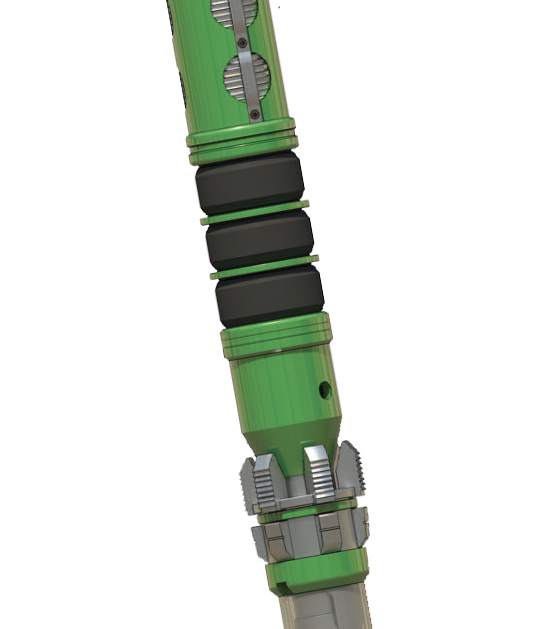

3 1/16" Coiled Tubing Hanger 10M Pressure Rated

Coiled Tubing Hanger

Also known as:

Coiled Tubing Wellhead Hanger, CT, CT Hanger

3 1/16" Coiled Tubing Hanger 10M Pressure Rated

Coiled Tubing Hanger

Also known as:

Coiled Tubing Wellhead Hanger, CT, CT HangerBuy

Made to Order

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

4 - 6 WeeksNote:

The 3 1/16” 10M Coiled Tubing Hanger supports larger coiled tubing and heavy tools during high pressure well interventions, ensuring secure tubing suspension and pressure control.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The 3 1/16” 10M Coiled Tubing Hanger is an essential wellhead device designed to support larger diameter coiled tubing and heavier downhole tools during well intervention and maintenance operations in high-pressure environments, with a pressure rating up to 10,000 psi. Coiled tubing is a continuous, flexible steel pipe deployed into wells to perform tasks such as cleaning, stimulation, and diagnostics without stopping production. This hanger securely suspends the tubing at the surface while maintaining pressure containment, allowing operators to carry out work safely and efficiently.

Its design accommodates the demands of deeper or more challenging wells where larger tubing and heavier tool strings are necessary. By providing a reliable seal and mechanical support, the hanger helps preserve well integrity and operational safety. Integration with standard wellhead equipment ensures compatibility and ease of installation.

Technical Specifications

| Size | 3 1/16” |

| Pressure Rating | 10M (10,000 psi) |

| Flanged Connections | API 6B & API 6BX |

| Supported Tubing Sizes | 1”, 1¼”, 1½”, 1¾” O.D. coiled tubing |

| Seal Type | Secondary annulus seal provided by wireline entry sub |

| Material | High-strength alloy steel |

| Standards Compliance | API |

| Power Source | Electric |

| Frequency | 50 to 60 Hz |

| Feature | Designed to support heavy duty coiled tubing down hole tool strings. |

Features and Benefits

- Designed for integration with standard wellhead equipment.

- Enables safe and reliable operation in high-pressure wells.

- Enhances operational safety through effective sealing and tubing control.

- Provides a secure secondary annulus seal to prevent leaks and control well pressure.

- Rated for high-pressure environments (up to 10,000 psi).

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

Coiled tubing is a continuous, flexible steel pipe widely used in well intervention and maintenance operations, allowing operators to clean, stimulate, log, or deploy tools inside the wellbore without shutting down production. This capability makes coiled tubing an efficient and cost-effective solution to maintain well health and improve productivity.

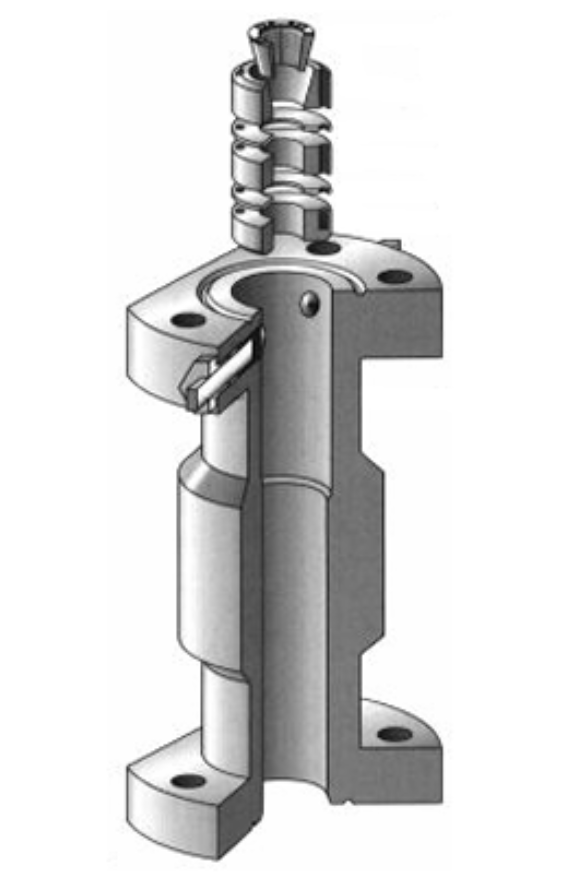

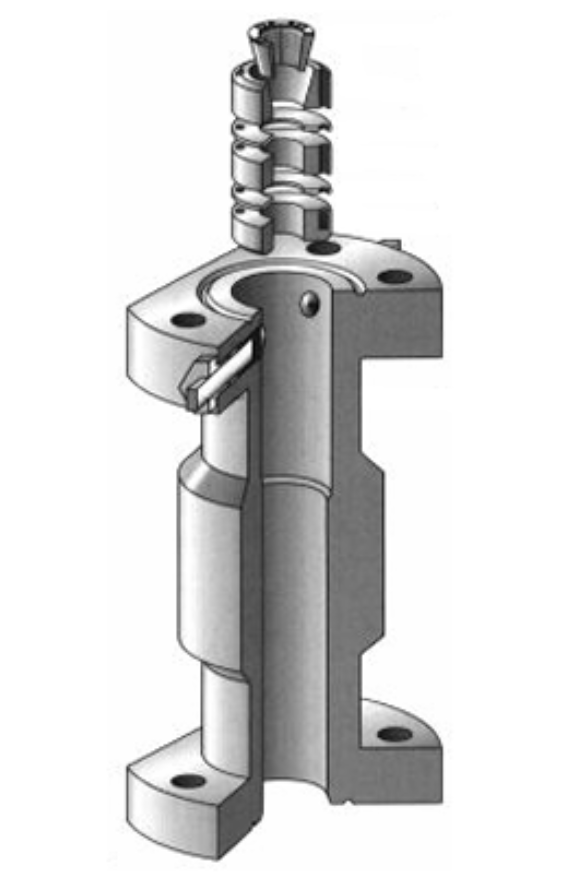

The 3 1/16” 10M Coiled Tubing Hanger is designed to support larger diameter coiled tubing and heavier tool strings required for more demanding or deeper well operations. The size “3 1/16”” refers to the wellhead bore size that the hanger fits into, while the “10M” indicates its pressure rating of 10,000 psi, meaning it is built to withstand high-pressure environments typically found in advanced well interventions.

This hanger is rated to maintain pressure containment during interventions in high-pressure wells, ensuring safe operations and protecting well integrity. It accommodates coiled tubing sizes ranging from 1 inch up to 1¾ inches outer diameter, which allows the deployment of heavier and more complex downhole tools needed for challenging well conditions. Its rugged construction is engineered to withstand mechanical stresses from heavy tool strings and high pressures without compromising performance.

Designed with flanged connections compatible with API 6B and 6BX standards, the hanger integrates seamlessly with existing wellhead equipment, simplifying installation and maintenance. An important feature of this model is the wireline entry sub, which guides wireline tools into the tubing bore, facilitating additional intervention tasks. The wireline entry sub also provides a secondary annulus seal that prevents fluid or gas leaks and restricts any upward movement of the tubing, enhancing operational safety.

The hanger maintains a secure secondary annulus seal around the tubing, which is critical for isolating pressure zones and protecting against leaks during live well operations. This versatility makes the hanger suitable for various well intervention activities such as well cleanouts, acidizing, logging, and tool deployment, particularly in situations where larger tubing and higher pressures are involved.

The 3 1/16” size strikes a balance between tubing size and wellhead bore capacity. It is larger than smaller hanger sizes, allowing operators to use coiled tubing capable of handling more demanding operational requirements. Its high-pressure rating ensures safe operation in wells where pressures can reach or exceed 10,000 psi, common in deeper or complex reservoirs.