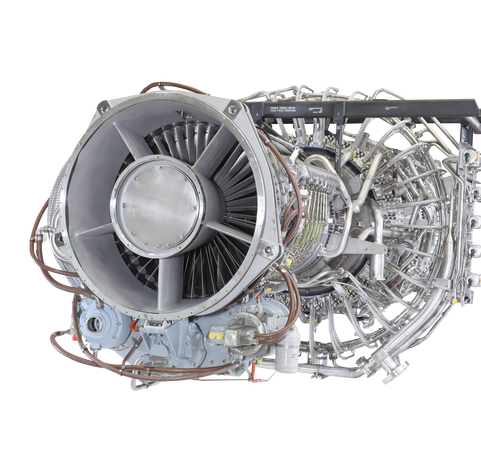

3” Sleeve Style Hot Air Purge Valve

Hot Air Purge Valve

Also known as:

Purge Valve, Bleed Valve

3” Sleeve Style Hot Air Purge Valve

Hot Air Purge Valve

Also known as:

Purge Valve, Bleed ValveBuy

Made to Order

Product

Price:

Request for QuoteShipping:

Air freightDelivery Time:

2 WeeksNote:

3” sleeve-style hot air purge valve controls compressor bleed air to safely purge fuel systems in aero-derivative gas turbines. It handles high temperatures and pressures.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The 3” sleeve-style hot air purge valve is a key safety and control device used in aero-derivative gas turbines. It regulates hot compressor bleed air to clean fuel lines during fuel switching, preventing damage and ensuring reliable operation. Known for fast response and high durability, it helps maintain turbine efficiency and safety under demanding conditions.

Technical Specifications

| Physical Size | 7.5” wide, 25” high |

| Weight | 84 to 91 pounds |

| Flange Type | 3.0” ANSI B16.5 CL 600 raised face flanges |

| Line Pressure | 0 to 500 psig |

| Actuation Pressure | 80 to 125 psig |

| Fluid Temperature | 32 to 1100°F (bleed air) |

| Ambient Temperature | -20°F to 240°F |

| Heat Soak | 400°F maximum ambient, 1 to 2 hours, de-energized |

| Flow | 1.2 pounds/sec compressor bleed air |

| Pressure Drop | 0.70 psid maximum at all normal operation conditions |

Features and Benefits

- Sleeve-style, elbow design for compact installation in gas turbine systems.

- Open and closed position indicating switch circuits.

- Used on both DLE and SAC gas turbines.

- Reliable purge control, efficient removal of residual fuels.

- Lightweight and compact.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The 3-inch sleeve-style hot air purge valve is designed for aero-derivative industrial gas turbines to control the flow of hot compressor bleed air used in critical purge operations. This valve is normally closed and solenoid-pilot actuated, available in two- or three-inch sizes with elbow sleeve design. It operates on 24 or 125 VDC power and is constructed with ANSI B16.5 Class 600 raised face flanges.

Key specifications include a physical size of approximately 7.5 inches wide and 25 inches high, weighing between 84 to 91 pounds. It can handle line pressures up to 500 psig and actuation pressures between 80 and 125 psig. The valve is rated to operate in fluid temperatures ranging from 32°F to 1100°F (bleed air), and can withstand ambient temperatures between –20°F and 240°F with heat soak up to 400°F for 1 to 2 hours when de-energized.

Performance characteristics include a flow capacity of about 1.2 pounds per second of compressor bleed air with a maximum pressure drop of 0.70 psi across normal operating conditions. Internal leakage is minimal, rated at 0.00025 pounds per minute. The valve features a rapid full stroke response time of 1 second for both opening and closing cycles. It includes a position indicating switch and supports continuous duty operation.

Functionally, this valve plays a crucial role in purging residual fuels, such as diesel, from the combustor fuel lines when switching fuels, preventing deposits that can impair turbine performance or cause damage. The valve is often installed in pairs for dual redundancy to enhance safety and operational reliability. With millions of field operating hours, this design reflects high durability and precise control essential for efficient and safe turbine operation.

Engineering Data