Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

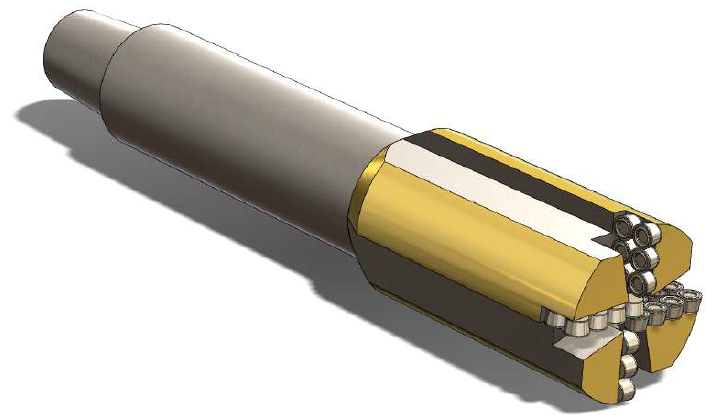

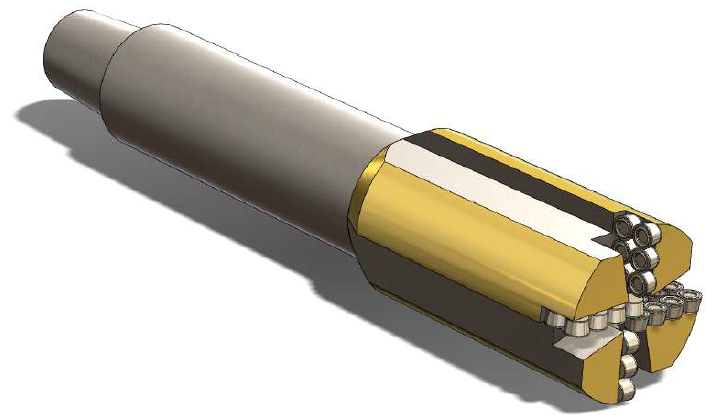

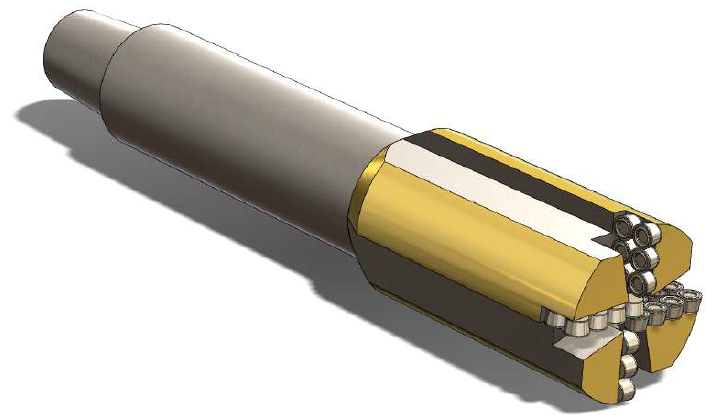

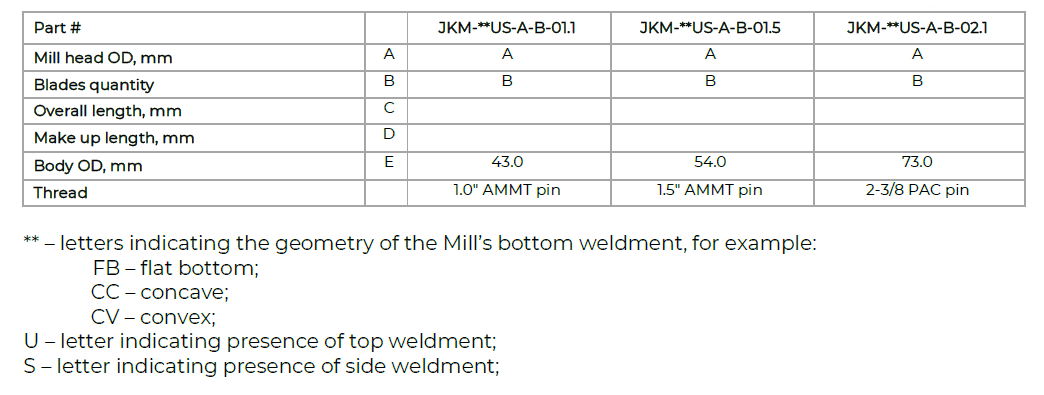

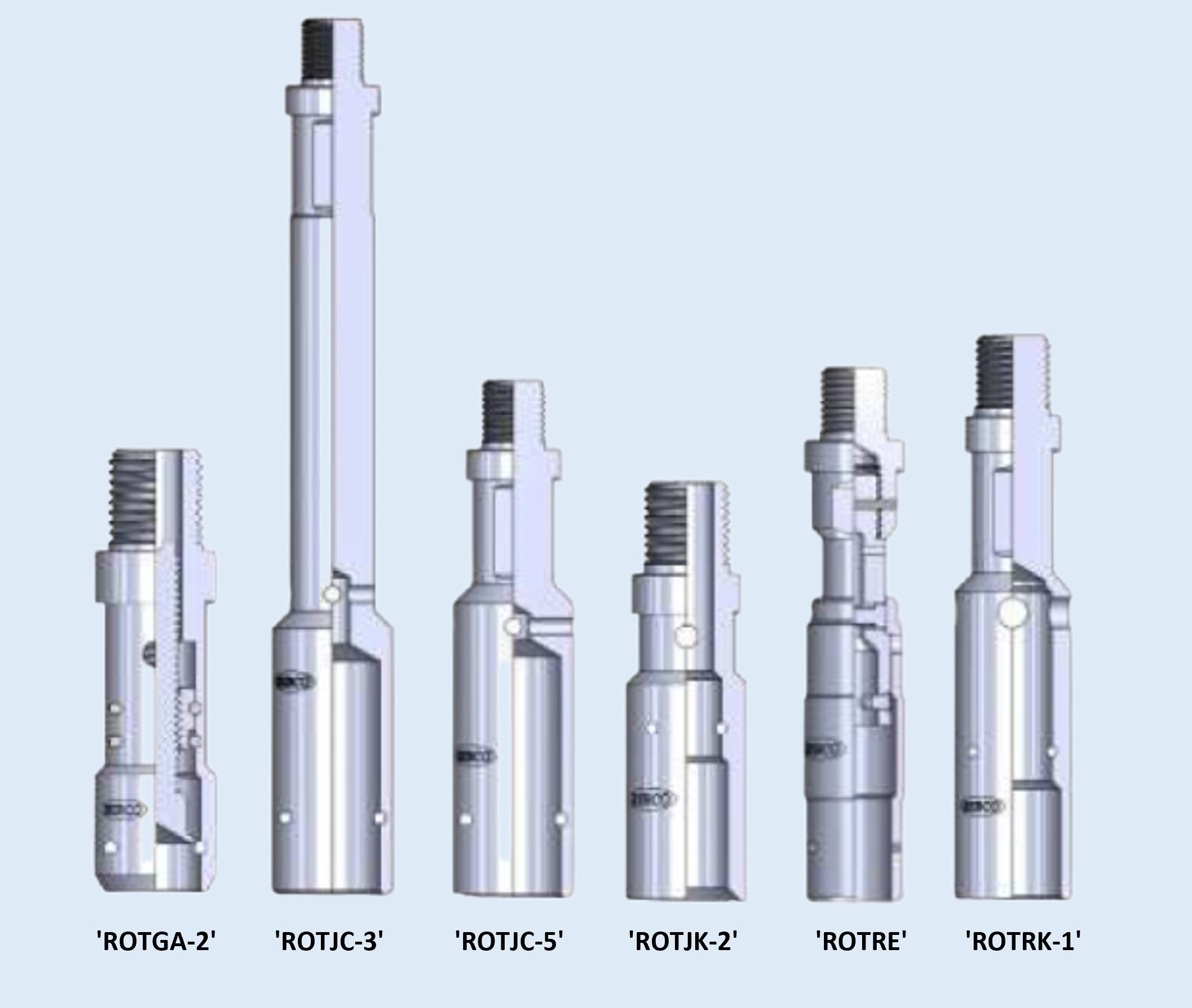

JKM Junk Mill

Also known as:

Coiled Tubing Downhole Tool, BHABuy

Made to Order

Manufacturer

New

API

Land Freight

Title:

Junk MillModel Number:

JKM-**US-A-B-01.1Availability:

Made to OrderDelivery Time (weeks):

2 - 4 WeeksIn Stock

Transaction Type

BuyCondition

NewWeight

Based on Specs lbsLocation

CanadaCompany Type

ManufacturerQuality Assurance

APIPrice

Request for QuoteMaterial

SteelBrand Name

Marlin Oil ToolsShipping

Land FreightNotes

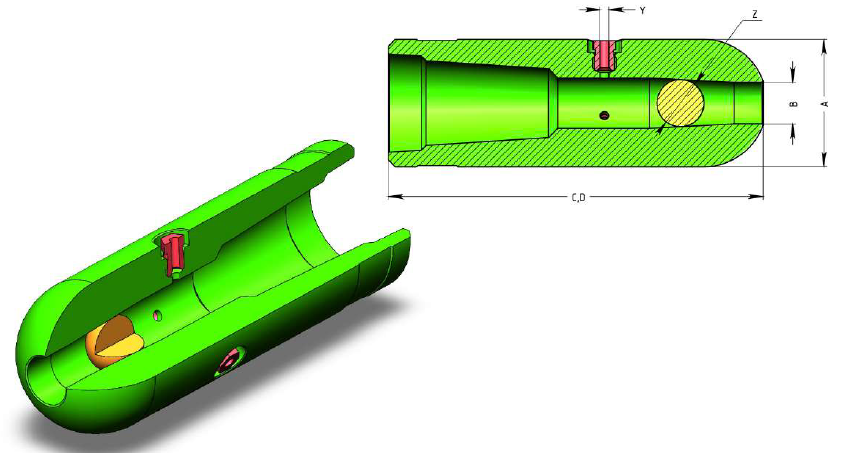

The mill consists of the body and carbide welded on the body.

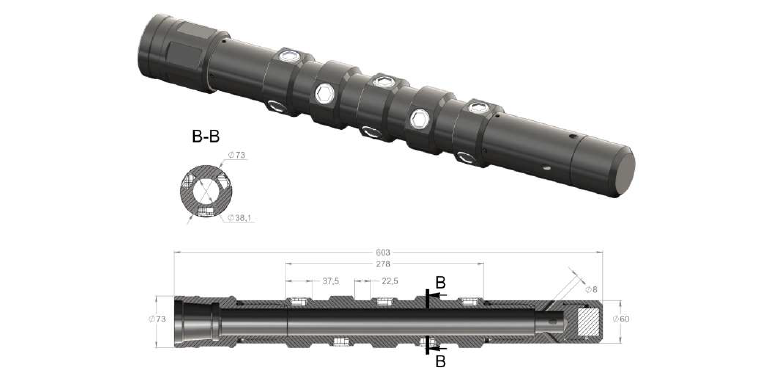

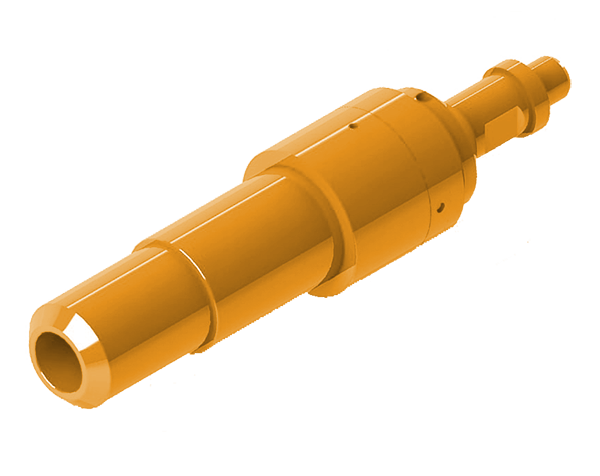

Internal Dimple Connector for Coiled Tubing

IDC Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

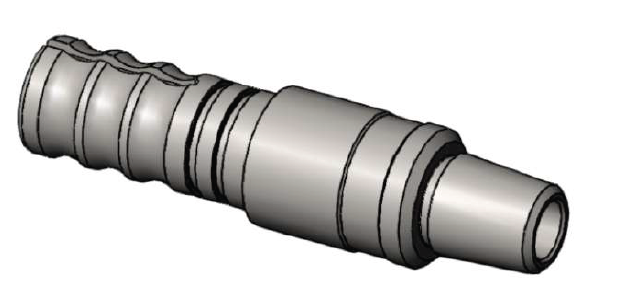

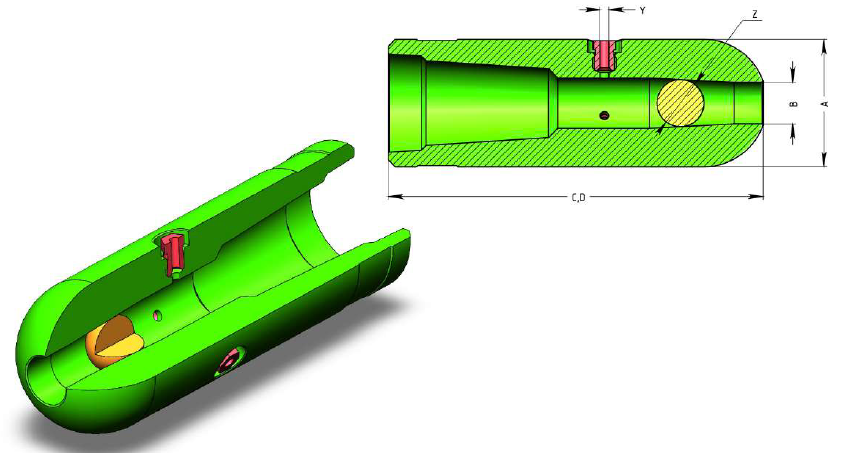

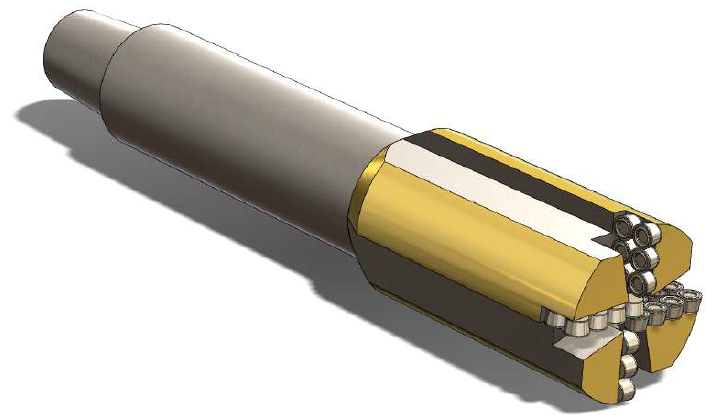

Introducing the IDC (Internal Dimple Connector) by Marlin Oil Tools: The Premier Solution for Secure Coiled Tubing Connections in Oil and Gas Well Interventions Marlin Oil Tools proudly unveils the IDC (Internal Dimple Connector), a breakthrough in coiled tubing connector technology, engineered to provide a seamless and secure connection between the smooth lower end of coiled tubing (CT) and various downhole tools essential for effective well intervention operations. Optimized for the oil and gas industry, the IDC ensures a robust link, enhancing operational efficiency and safety. Discover the unparalleled benefits of incorporating the IDC into your well intervention toolkit. Key Features of the IDC (Internal Dimple Connector): Optimized Connection Design: The IDC features innovative spherical recesses in its upper part, designed specifically for the precise and secure fixing of coiled tubing through mechanical or hydraulic pressing. This design ensures a tight and reliable connection, crucial for the demanding environments of well intervention jobs. Threaded Lower Part for Tool Attachment: The connector’s lower section is equipped with a thread to facilitate the easy attachment of downhole tools. This feature allows for a versatile use of the IDC across a wide range of well intervention activities, making it a staple in any operation. Enhanced Sealing with FKM 90 O-rings: Equipped with two O-rings made from the durable FKM 90 material, the IDC offers superior sealing capabilities. This design effectively isolates the internal space of the connector and the annulus, preventing fluid leakage and ensuring the integrity of well operations. Easy and Efficient Installation: The installation of the IDC is streamlined and efficient, compatible with dimple tools for both mechanical and hydraulic pressing. This ease of installation reduces operational downtime, enabling quicker transitions between tasks and enhancing overall productivity. Elevate your well intervention operations with the IDC (Internal Dimple Connector) from Marlin Oil Tools, a leading solution for coiled tubing applications in the oil and gas industry. Designed to securely link the smooth lower end of coiled tubing to downhole tools, the IDC features advanced spherical recesses for a reliable connection and a threaded lower part for easy tool attachment. With dual O-rings made from high-quality FKM 90 material, it offers exceptional sealing, protecting your operations from fluid leakage. Ideal for a variety of well intervention jobs, the IDC is engineered for easy installation with mechanical or hydraulic pressing, ensuring operational efficiency and safety. Choose the IDC for a trusted connection in your coiled tubing operations. Why Choose the IDC from Marlin Oil Tools? Reliability: Engineered for the harsh conditions of downhole operations, the IDC provides a secure and reliable connection, minimizing the risk of disconnections or failures during critical well intervention tasks. Versatility: The threaded lower part of the IDC makes it compatible with a broad array of downhole tools, offering unparalleled flexibility in well intervention operations. Operational Efficiency: Designed for quick and easy installation, the IDC reduces downtime and increases the efficiency of well intervention activities. Safety and Integrity: With its superior sealing capabilities, the IDC enhances the safety and integrity of well operations, ensuring a leak-free connection. Marlin Oil Tools is committed to advancing the efficiency and safety of oil and gas operations with innovative solutions like the IDC (Internal Dimple Connector). Contact us today to learn how our cutting-edge coiled tubing tools can optimize your well intervention strategies.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

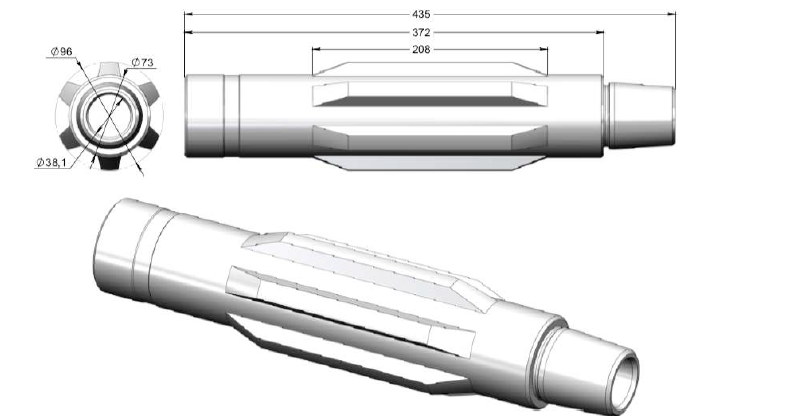

Introducing the MGN Radial Downhole Magnet from Marlin Oil Tools: Your Premier Solution for Well Cleaning and Metal Debris Removal Marlin Oil Tools is proud to unveil the MGN Radial Downhole Magnet, a highly efficient downhole tool designed specifically for the oil and gas industry to address the critical need for well cleaning and maintenance. Engineered to remove small metal debris, such as chips and scale, the MGN Radial Downhole Magnet is essential for maintaining well integrity and preventing operational complications. Key Features of the MGN Radial Downhole Magnet: Efficient Debris Removal: Utilizes a powerful radial magnetic field to capture and remove small metal debris accumulated during the operation of metal tools and milling operations. Prevention of Operational Complications: By extracting small metal parts and foreign objects, the MGN Radial Downhole Magnet minimizes the risk of well complications or accidents, ensuring smoother operations. Versatile Design: Features various designs with magnetic surfaces located along the tool body or from the end, tailored to maximize debris capture efficiency. Simultaneous Well Flushing Capability: Equipped with an internal passage hole, it allows for well flushing simultaneously with magnet operation, enhancing cleaning efficiency. Customizable Connections: Offers the flexibility to manufacture any connecting threads as per customer requirements, ensuring compatibility with existing downhole tool configurations. Crucial for Well Preparation: Acts as a vital step in well work preparation, ensuring a clean operational environment free from hazardous metal debris. Elevate your well maintenance regime with the MGN Radial Downhole Magnet from Marlin Oil Tools, a leading-edge solution crafted for the effective removal of metal debris in oil and gas wells. This downhole magnet, engineered for precision and efficiency, safeguards your well operations against potential complications caused by foreign metal objects and accumulated debris. With its versatile design and simultaneous well flushing capability, the MGN Radial Downhole Magnet is indispensable for any well intervention or maintenance activity. Opt for Marlin Oil Tools’ customizable and reliable downhole magnet to ensure your well remains clean, safe, and productive. Why Choose the MGN Radial Downhole Magnet from Marlin Oil Tools? Targeted Debris Removal: Optimized for capturing a wide range of metal debris, ensuring a clean wellbore. Operational Safety: Significantly reduces the risk of well operation complications and accidents. Enhanced Cleaning Efficiency: Simultaneous flushing feature streamlines well cleaning processes. Flexible and Compatible: Customizable thread options offer seamless integration into your BHA. Essential for Well Maintenance: A critical tool for preparing wells for intervention and maximizing operational longevity. The MGN Radial Downhole Magnet by Marlin Oil Tools represents the pinnacle of downhole cleaning technology, providing operators with a robust tool for ensuring well integrity and operational efficiency. Incorporate the MGN Radial Downhole Magnet into your well maintenance toolkit for a cleaner, safer, and more productive well operation.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the KNJ Knuckle Joint from Marlin Oil Tools: The Essential Downhole Tool for Enhanced Flexibility in Well Intervention Operations Marlin Oil Tools proudly presents the KNJ Knuckle Joint, a state-of-the-art downhole tool engineered to provide unparalleled flexibility to the Bottom Hole Assembly (BHA) during well intervention tasks. Designed to navigate through the most challenging sections of the well, including sharp narrows, thresholds, and various obstacles, the KNJ Knuckle Joint is an indispensable tool for ensuring the success and efficiency of well interventions. Key Features of the KNJ Knuckle Joint: Superior BHA Flexibility: The KNJ Knuckle Joint significantly enhances the flexibility of the BHA, enabling it to easily navigate through complex wellbore geometries. Overcomes Downhole Obstacles: Specifically designed to aid in overcoming difficult wellbore obstacles, the KNJ ensures smooth passage in areas that would otherwise pose significant challenges. Seamless Integration: The KNJ Knuckle Joint integrates seamlessly with other downhole tools within the BHA, providing a cohesive solution for well intervention operations. Optimized Well Intervention: By allowing for enhanced maneuverability and flexibility, the KNJ Knuckle Joint optimizes well intervention procedures, reducing the risk of tool sticking and minimizing the need for additional runs. SEO Optimized Description for Marlin Oil Tools’ KNJ Knuckle Joint: Elevate your well intervention capabilities with the KNJ Knuckle Joint from Marlin Oil Tools, a leading-edge solution designed to enhance the flexibility and maneuverability of the BHA in challenging wellbore environments. Tailored for navigating sharp narrows, thresholds, and other downhole obstacles, the KNJ Knuckle Joint is essential for any operation requiring advanced BHA adaptability. Its seamless integration with other downhole tools ensures a comprehensive approach to well intervention, making the KNJ Knuckle Joint a must-have for overcoming complex well geometries and optimizing intervention success. Why Choose the KNJ Knuckle Joint from Marlin Oil Tools? Enhanced Operational Flexibility: Maximizes BHA adaptability to navigate complex wellbore paths efficiently. Critical for Challenging Wellbores: Designed to tackle the most difficult downhole conditions, ensuring smooth operation. Increases Intervention Success: Reduces the likelihood of tool sticking and operational delays, enhancing overall success rates. Versatile and Reliable: A versatile tool that offers reliability and performance, crucial for a wide range of well intervention scenarios. The KNJ Knuckle Joint by Marlin Oil Tools represents the pinnacle of downhole tool innovation, offering operators the flexibility and reliability needed to tackle the most challenging well intervention tasks. Incorporate the KNJ Knuckle Joint into your well intervention toolkit to achieve superior performance and operational efficiency.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the JWN Jet Wash Nozzle from Marlin Oil Tools: A Revolution in Well Intervention and Perforation Technology Marlin Oil Tools is proud to unveil the JWN Jet Wash Nozzle, an advanced downhole tool specifically engineered for precision well intervention and perforation tasks. As a critical component of the Bottom Hole Assembly (BHA), the JWN Jet Wash Nozzle is designed to enhance the efficiency of perforating casing or tubing by utilizing a high-speed jet of a gel-sand mixture directed at the well's inner casing wall. Here’s why the JWN Jet Wash Nozzle is a game-changer in the oil and gas industry. Key Features of the JWN Jet Wash Nozzle: Precision Perforation: The JWN Jet Wash Nozzle delivers a high-velocity jet stream of a gel-sand mixture, enabling precise and efficient perforation of the casing or tubing. Abrasive-Resistant Materials: Constructed from materials that resist wear from abrasive particles, ensuring longevity and reliability under harsh downhole conditions. Versatile Design Options: Available in a basic design for continuous circulation or a ball-activated design that opens nozzles only after a ball drop, providing flexibility for specific operational needs. Enhanced Well Productivity: By performing abrasive cuts through metal, cement, and part of the surrounding rock, the JWN enhances well connectivity and productivity. Seamless BHA Integration: Designed to run in hole as part of the BHA alongside other downhole tools, the JWN Jet Wash Nozzle is compatible with a wide range of well intervention equipment. Elevate your well intervention and perforation operations with the JWN Jet Wash Nozzle from Marlin Oil Tools, a leading-edge solution designed for optimal efficiency and precision in the oil and gas sector. Featuring abrasive-resistant nozzles and a high-speed gel-sand mixture jet, the JWN Jet Wash Nozzle precisely perforates casing and tubing, improving well productivity. With options for continuous circulation or ball-activated operation, this tool offers unparalleled flexibility and durability for your well intervention needs. Choose the JWN Jet Wash Nozzle for a reliable, efficient, and versatile solution in enhancing well connectivity and output. Why Choose the JWN Jet Wash Nozzle from Marlin Oil Tools? Targeted Perforation: Achieves precise perforation for improved fluid flow and well performance. Durable Construction: Built to withstand the rigors of abrasive materials, ensuring tool integrity and operational longevity. Operational Flexibility: Adapts to various well intervention scenarios with basic and ball-activated designs. Improved Efficiency: Reduces downtime and enhances well productivity through efficient and effective perforation. The JWN Jet Wash Nozzle by Marlin Oil Tools represents the pinnacle of well intervention technology, providing operators with a powerful tool for enhancing well integrity and performance. Incorporate the JWN Jet Wash Nozzle into your operations to achieve superior results in well perforation and intervention tasks.

Buy

Made to Order

Manufacturer

New

API

Land Freight

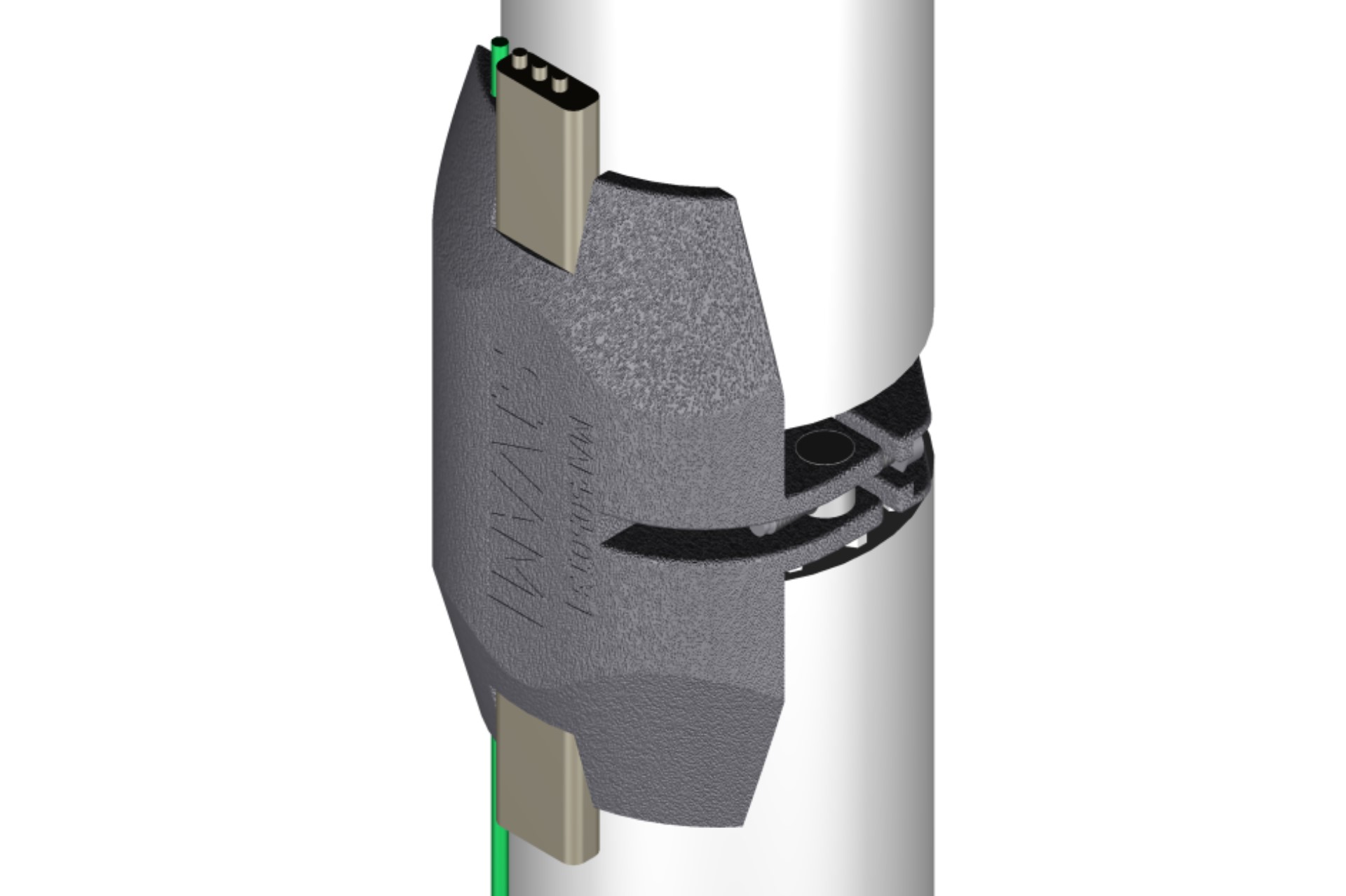

Anti-rotational internal Roll-on Connector for Coiled Tubing

Coiled Tubing Tools![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

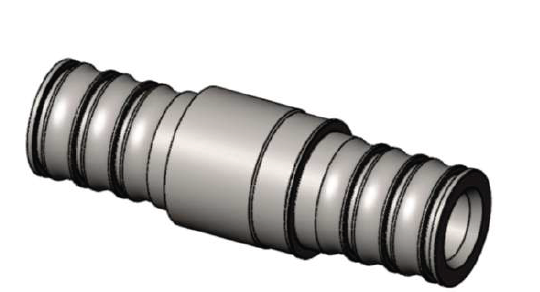

ARC Coiled Tubing Connector | Anti-Rotational Roll-On Tool | Marlin Oil Tools The ARC (Anti-rotational internal Roll-on Connector) from Marlin Oil Tools serves as the essential link between the smooth lower end of coiled tubing (CT) and any downstream downhole tool required for well intervention projects in the oil and gas industry. Featuring a unique design, the ARC seamlessly connects the smooth-walled CT with the threaded interface of downhole tools, ensuring efficient and reliable operations in challenging wellbore environments. Key Features: Three grooves in the upper part of the connector facilitate the secure attachment and rolling of the coiled tubing, enhancing stability and operational performance. The lower part of the ARC is equipped with a threaded interface, enabling seamless connection with various downhole tools featuring connecting threads. O-rings positioned below the grooves provide a robust barrier, effectively sealing against in-line working pressures and preventing leaks during operations. A strategically placed slot along the grooves offers a significant advantage, allowing for the internal welding seam of the coiled tubing to be securely locked during connector installation. This anti-rotational feature ensures the stability of the connector and minimizes the risk of rotation during operation. The ARC Coiled Tubing Connector from Marlin Oil Tools is engineered to deliver exceptional performance, reliability, and sealing capabilities in oil and gas coiled tubing applications. Experience enhanced efficiency and confidence in your well intervention projects with the ARC connector from Marlin Oil Tools.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Coiled Tubing Sliding Sleeve Activator

SSA Sliding SLeeve Actuator![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SSA (Sliding Sleeve Actuator) from Marlin Oil Tools: Revolutionizing Multistage Fracturing Operations Marlin Oil Tools proudly presents the SSA (Sliding Sleeve Actuator), a state-of-the-art downhole tool designed to optimize well intervention and multistage fracturing operations. Engineered to activate sliding sleeves with unparalleled efficiency and precision, the SSA is an essential tool for modern well completion strategies. By eliminating the need for traditional activation balls, the SSA streamlines fracturing operations, significantly reducing intervention times and enhancing overall well productivity. Key Features of the SSA (Sliding Sleeve Actuator): Efficient Sleeve Activation: The SSA is specifically designed to activate sliding sleeves in the liner of the well, targeting planned fracturing spots with accuracy. Simplifies Operations: Replaces the conventional method of dropping activation balls into the well, thereby simplifying the activation process. Rapid Deployment and Retrieval: Engineered for use with coil tubing, the SSA ensures quick deployment and retrieval, minimizing downtime in fracturing operations. Eliminates Milling or Catching: By using the SSA, the need to mill or catch activation balls post-fracturing is removed, enhancing operational safety and efficiency. Seamless Integration: Optimally designed to integrate with existing well completion setups, the SSA facilitates a smooth fracturing process. Precision in Fracturing: Offers precise control over the activation of sliding sleeves, ensuring effective multistage fracturing exactly where needed. Elevate your well intervention and fracturing operations with the SSA (Sliding Sleeve Actuator) from Marlin Oil Tools, a groundbreaking solution tailored for the oil and gas industry. This innovative downhole tool revolutionizes sliding sleeve activation during multistage fracturing, offering a more efficient and precise alternative to traditional activation balls. Designed for rapid deployment and retrieval via coil tubing, the SSA not only simplifies fracturing operations but also significantly enhances well productivity and safety. Choose the SSA for a streamlined, effective approach to modern well completions and fracturing. Why Choose the SSA from Marlin Oil Tools? Operational Efficiency: Dramatically reduces intervention times, allowing for faster and more efficient fracturing operations. Enhanced Safety and Simplicity: Removes the complexities and safety concerns associated with milling or catching traditional activation balls. Precision Activation: Ensures accurate activation of sliding sleeves, maximizing the effectiveness of multistage fracturing. Innovative Design: The SSA's design is optimized for ease of use with coil tubing, ensuring seamless operation and integration into fracturing workflows. The SSA (Sliding Sleeve Actuator) by Marlin Oil Tools represents the forefront of innovation in downhole tools, providing operators with an advanced solution to meet the challenges of today's fracturing operations. Incorporate the SSA into your well intervention toolkit to achieve superior efficiency, safety, and performance in multistage fracturing.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Back Pressure Valve for Coiled Tubing

BPV Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the BPV (Back Pressure Valve) from Marlin Oil Tools: The Essential Safety Barrier for Coiled Tubing Operations in the Oil and Gas Industry Marlin Oil Tools is proud to present our BPV (Back Pressure Valve), a paramount downhole tool designed to enhance safety and operational integrity during well intervention tasks. Engineered with precision and reliability, the BPV is an indispensable component for maintaining control over well pressure and ensuring the protection of coiled tubing (CT) from potential hazards. Here's a detailed look at the BPV's design, functionality, and benefits, making it a must-have tool for any oil and gas operation. Key Features of the BPV (Back Pressure Valve): Directional Fluid Flow Control: The BPV is designed to allow fluid flow exclusively in one direction—downwards. This capability is crucial for preventing backflow and maintaining operational control during well intervention processes. Dual Flapper Valve System: Equipped with two duplicate cartridges featuring reliable flapper valves, the BPV offers an enhanced level of safety and redundancy. This double flapper back pressure valve system ensures that even if one valve encounters an issue, the other can continue to function effectively, providing an uninterrupted safety barrier. Comprehensive Well Pressure Control: The primary function of the BPV is to act as a safety barrier, preventing well fluids from entering the coiled tubing through the bottom of the Bore Hole Assembly (BHA). This function is vital for the safety of operations and the preservation of equipment integrity. Protection Against Mechanical Particles and Aggressive Environments: In addition to controlling well pressure, the BPV serves an auxiliary role in protecting the coiled tubing from mechanical particles and potentially aggressive well environments, such as those containing H2S and CO2. These elements can cause significant damage to the CT if allowed entry, making the BPV's protective capability critical for long-term equipment durability. Essential Tool for Every Job: Given its crucial safety and protective functions, the BPV is typically run on each well intervention job, underscoring its importance in the toolkit of downhole operations. Elevate your well intervention safety and efficiency with the BPV (Back Pressure Valve) from Marlin Oil Tools, a leading solution in oil and gas coiled tubing tools. Designed for downhole applications, the BPV features a double flapper valve system to ensure fluid flows only downwards, creating an effective barrier against well pressure. This safety essential prevents well fluid backflow into the CT, offering protection from mechanical particles and harsh environments like H2S and CO2. With dual reliable cartridges, the BPV is a critical component for every well intervention job, safeguarding both personnel and equipment by maintaining operational integrity and preventing damage from aggressive well conditions. Why Choose the BPV from Marlin Oil Tools? Unparalleled Safety and Control: Provides a reliable safety barrier for well pressure control, crucial for operational safety. Dual Valve Redundancy: Ensures continued operation and safety even if one valve fails, thanks to its double flapper valve design. Comprehensive Protection: Guards coiled tubing against mechanical damage and corrosion from aggressive well environments. Operational Necessity: An indispensable tool for every well intervention job, highlighting its importance in maintaining a safe and efficient operation. The BPV (Back Pressure Valve) by Marlin Oil Tools represents the pinnacle of safety and efficiency in coiled tubing operations within the oil and gas industry. Incorporate the BPV into your operations to ensure the highest standards of safety and equipment integrity. Contact Marlin Oil Tools today to learn more about how our innovative solutions can support your operational needs.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Coiled Tubing Hydraulic Setting Tool

SST Hydraulic Setting Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SST Hydraulic Setting Tool from Marlin Oil Tools: The Ultimate Mechanical Solution for Downhole Equipment Setting Marlin Oil Tools is proud to present the SST Hydraulic Setting Tool, a fully mechanical downhole tool engineered to revolutionize the setting of bridge plugs and cement retainers within the well casing. Designed for versatility, the SST can be deployed via coil tubing or traditional tubing, making it a crucial component for enhancing well integrity and operational efficiency in oil and gas interventions. Key Features of the SST Hydraulic Setting Tool: Versatile Application: Compatible with both coil tubing and traditional tubing, offering flexible deployment options for various well intervention scenarios. Mechanical Activation: Utilizes a simple yet effective mechanical activation process, where a ball landing in the piston initiates the setting mechanism. Precise Setting Capability: Provides accurate and reliable setting of bridge plugs and cement retainers, crucial for wellbore stability and integrity. High-Pressure Performance: Engineered to withstand the shear pressure required to move the piston and secure the downhole equipment in place. Optimized for Well Interventions: Enhances the efficiency and safety of well interventions by ensuring the precise placement of downhole tools. Ease of Operation: The straightforward mechanical design ensures ease of use, minimizing potential operational complications. Elevate your well intervention and completion processes with the SST Hydraulic Setting Tool from Marlin Oil Tools, a premier mechanical solution designed for the oil and gas industry. This innovative tool simplifies the setting of bridge plugs and cement retainers, ensuring optimal well casing integrity. Compatible with both coil tubing and traditional tubing, the SST offers unparalleled versatility and reliability. With its mechanical activation mechanism and high-pressure performance, the SST Hydraulic Setting Tool is essential for achieving precise downhole equipment placement, enhancing operational efficiency and well integrity. Choose the SST for a streamlined, effective approach to well interventions. Why Choose the SST Hydraulic Setting Tool from Marlin Oil Tools? Flexible Deployment Options: Ensures compatibility with various intervention methods, increasing tool utility. Reliable Mechanical Activation: Simplifies the setting process, reducing the risk of operational errors. Precision in Downhole Settings: Guarantees the accurate placement of bridge plugs and cement retainers for improved well performance. Durability Under Pressure: Built to endure the rigorous conditions of downhole operations, offering lasting performance. The SST Hydraulic Setting Tool by Marlin Oil Tools represents the cutting edge in downhole mechanical solutions, providing operators with a powerful tool for enhancing well completion and intervention outcomes. Incorporate the SST into your operations to ensure efficient, accurate, and reliable downhole equipment setting.

Buy

Made to Order

Manufacturer

New

API

Land Freight

External Slip type Connector for Coiled Tubing

ESC Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the Innovative ESC (External Slip Type Connector) by Marlin Oil Tools: Your Solution for Reliable Coiled Tubing Connections in the Oil and Gas Industry Marlin Oil Tools is at the forefront of delivering cutting-edge solutions tailored for the dynamic needs of the oil and gas sector. Our latest innovation, the ESC (External Slip Type Connector), is designed to revolutionize well intervention operations by providing a secure and efficient method to connect the smooth lower end of coiled tubing (CT) to any downhole tool. Here’s why the ESC stands as a pivotal advancement in coiled tubing technology: Key Features of the ESC (External Slip Type Connector): Innovative Connection Design: The ESC boasts an internal collet mechanism with inward-pointing teeth, ensuring a tight grip on the smooth outer wall of the CT. This design guarantees a secure connection, vital for the successful execution of well intervention jobs. Enhanced Sealing Capabilities: Equipped with two O-rings made from the highly durable FKM 90 material, the ESC offers exceptional sealing, isolating the internal space of the connector from the annulus. This feature is crucial for maintaining the integrity of well operations and preventing fluid leakage. Robust and Reliable: The use of a trapezoidal thread in conjunction with high-quality metals provides a connection that is not only reliable but also capable of withstanding the rigorous demands of downhole activities. The ESC is built to ensure the safety and efficiency of well work. Versatile Tool Connection: The lower housing of the ESC features a standard working taper thread, making it compatible with a wide range of downhole tools. This versatility allows for seamless make-up and enhances the tool's utility across various well intervention scenarios. Marlin Oil Tools presents the ESC (External Slip Type Connector), an essential coiled tubing tool for oil and gas well intervention. Designed to securely link the smooth lower end of CT to threaded downhole tools, the ESC is engineered for reliability and efficiency. Featuring an internal collet with inward-pointing teeth for a firm grip, and dual O-rings made from FKM 90 for superior sealing, this connector ensures operational integrity. With its trapezoidal thread and high-quality metal construction, the ESC stands as a beacon of durability in harsh downhole environments. Its standard working taper thread accommodates various downhole tools, making it a versatile addition to your well intervention arsenal. Why Choose the ESC from Marlin Oil Tools? Security and Efficiency: The ESC’s innovative design ensures a secure connection between coiled tubing and downhole tools, optimizing well intervention operations. Superior Sealing: With its advanced sealing capabilities, the ESC prevents fluid leakage, protecting the well's integrity. Durability: Built with high-quality materials and a robust thread design, the ESC is designed to endure the toughest downhole conditions. Versatility: Its compatibility with a broad range of downhole tools makes it a flexible solution for various well intervention needs. Elevate your well intervention operations with the ESC (External Slip Type Connector) from Marlin Oil Tools. Contact us today to discover how our solutions can enhance your efficiency and operational success in the oil and gas industry.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SFF Surface Filter from Marlin Oil Tools: The Ultimate Solution for Protecting Your Downhole Equipment Marlin Oil Tools is proud to offer the SFF Surface Filter, a highly efficient tool designed to safeguard your downhole equipment by filtering mechanical particles from the liquid flow. Engineered with precision, the SFF Surface Filter is an essential addition to any oil and gas operation, ensuring the longevity and reliability of your valuable downhole tools. Key Features of the SFF Surface Filter: Advanced Filtration Technology: Utilizes a wire wound welded to the frame, creating gaps smaller than the permissible size of particles, thereby capturing and retaining mechanical impurities as the liquid flows through. Customizable Filtration Levels: Offers versatile filtration options with membrane fineness primarily available in 0.25 mm, 0.5 mm, and 0.9 mm, allowing operators to select the appropriate level of filtration for their specific well conditions. Durable and Reliable Design: Crafted for durability and long-term use, the SFF Surface Filter stands up to the demanding conditions of oil and gas extraction environments. Protects Sensitive Downhole Tools: Especially beneficial for tools that are highly sensitive to mechanical impurities, such as downhole mud motors with Metal-to-Metal power sections and downhole gas separators. Easy Installation: Designed for straightforward installation in the pipeline running from the pump to the well, ensuring seamless integration into your existing workflow. Enhanced Operational Efficiency: By preventing mechanical particle contamination, the SFF Surface Filter contributes to the smooth operation and reduced maintenance needs of downhole equipment, ultimately saving time and costs. Elevate the protection and efficiency of your oil and gas operations with the SFF Surface Filter from Marlin Oil Tools, a premier downhole tool solution engineered to filter mechanical particles from liquid flows. Featuring advanced filtration technology and customizable filtration levels, the SFF Surface Filter is designed to meet the rigorous demands of the oil and gas industry, ensuring the protection and longevity of sensitive downhole equipment. Whether you're dealing with downhole mud motors, gas separators, or other critical tools, the SFF Surface Filter offers a reliable, durable, and easy-to-install solution to maintain clean liquid flows and enhance operational efficiency. Opt for the SFF Surface Filter and invest in the safety and productivity of your downhole operations. Why Choose the SFF Surface Filter from Marlin Oil Tools? Superior Protection: Provides unmatched filtration to protect downhole equipment from mechanical impurities. Operational Versatility: Adaptable to a wide range of oil and gas operations with customizable filtration to suit diverse needs. Long-lasting Durability: Built to withstand the harsh conditions of oil and gas extraction, ensuring reliability and longevity. Cost-Efficient Maintenance: Reduces the need for frequent downhole tool maintenance, saving both time and operational costs. The SFF Surface Filter by Marlin Oil Tools represents the forefront of filtration technology in the oil and gas industry, providing a vital solution for maintaining the integrity and efficiency of your downhole equipment. Choose the SFF Surface Filter for an enhanced level of protection and operational excellence in your well interventions.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SBA Straight Bar from Marlin Oil Tools: The Essential Downhole Tool for Enhanced Well Intervention Precision Marlin Oil Tools proudly presents the SBA Straight Bar, a specially designed downhole tool that revolutionizes well intervention operations. As an integral part of the Bottom Hole Assembly (BHA), the SBA Straight Bar addresses the critical challenge of coil tubing deformation, ensuring a straighter and more effective pathway for well intervention tools. Key Features of the SBA Straight Bar: Enhanced BHA Stability: The SBA Straight Bar provides the necessary rigidity and straightness to the BHA, minimizing the risk of deformation and ensuring smoother operations. Improved Wellbore Navigation: By maintaining a straighter path, the SBA Straight Bar significantly reduces the chances of the BHA resting against the well walls or encountering obstacles during transitions. Optimal Centering: Its rigid and straight design aids in better centering of the BHA within the wellbore, crucial for the precision of well intervention tasks. Seamless Passage: The SBA Straight Bar facilitates seamless passage through wellbore expansions and recessions, including critical points like blowout preventers, enhancing operational safety and efficiency. Versatile Integration: Designed for easy integration into any BHA configuration, the SBA Straight Bar is suitable for a wide range of well intervention activities, offering unparalleled adaptability. Elevate your well intervention strategies with the SBA Straight Bar from Marlin Oil Tools, a leading-edge solution designed to combat coil tubing deformation and ensure precise downhole operations in the oil and gas industry. The SBA Straight Bar enhances BHA stability, improves wellbore navigation, and ensures optimal centering and seamless passage through wellbore transitions. This tool is an indispensable addition to your BHA, providing the rigidity and straightness necessary for effective well intervention. Choose the SBA Straight Bar for a reliable, efficient, and versatile solution to well intervention challenges. Why Choose the SBA Straight Bar from Marlin Oil Tools? Superior Operational Precision: Ensures straighter coil tubing pathways for enhanced precision in well intervention tasks. Increased Operational Safety: Minimizes the risk of BHA hang-ups and obstructions, ensuring safer operations. Adaptability to Well Conditions: Capable of navigating through complex well architectures, including areas of expansion and recession. Streamlined Well Intervention: Promotes smoother, faster, and more efficient well intervention procedures. The SBA Straight Bar by Marlin Oil Tools represents the forefront of downhole tool technology, providing operators with the means to enhance well intervention accuracy and operational success. Incorporate the SBA Straight Bar into your well intervention toolkit to achieve superior performance and outcomes.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Coiled Tubing Hydraulic Setting Tool

SST Hydraulic Setting Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SST Hydraulic Setting Tool from Marlin Oil Tools: The Ultimate Mechanical Solution for Downhole Equipment Setting Marlin Oil Tools is proud to present the SST Hydraulic Setting Tool, a fully mechanical downhole tool engineered to revolutionize the setting of bridge plugs and cement retainers within the well casing. Designed for versatility, the SST can be deployed via coil tubing or traditional tubing, making it a crucial component for enhancing well integrity and operational efficiency in oil and gas interventions. Key Features of the SST Hydraulic Setting Tool: Versatile Application: Compatible with both coil tubing and traditional tubing, offering flexible deployment options for various well intervention scenarios. Mechanical Activation: Utilizes a simple yet effective mechanical activation process, where a ball landing in the piston initiates the setting mechanism. Precise Setting Capability: Provides accurate and reliable setting of bridge plugs and cement retainers, crucial for wellbore stability and integrity. High-Pressure Performance: Engineered to withstand the shear pressure required to move the piston and secure the downhole equipment in place. Optimized for Well Interventions: Enhances the efficiency and safety of well interventions by ensuring the precise placement of downhole tools. Ease of Operation: The straightforward mechanical design ensures ease of use, minimizing potential operational complications. Elevate your well intervention and completion processes with the SST Hydraulic Setting Tool from Marlin Oil Tools, a premier mechanical solution designed for the oil and gas industry. This innovative tool simplifies the setting of bridge plugs and cement retainers, ensuring optimal well casing integrity. Compatible with both coil tubing and traditional tubing, the SST offers unparalleled versatility and reliability. With its mechanical activation mechanism and high-pressure performance, the SST Hydraulic Setting Tool is essential for achieving precise downhole equipment placement, enhancing operational efficiency and well integrity. Choose the SST for a streamlined, effective approach to well interventions. Why Choose the SST Hydraulic Setting Tool from Marlin Oil Tools? Flexible Deployment Options: Ensures compatibility with various intervention methods, increasing tool utility. Reliable Mechanical Activation: Simplifies the setting process, reducing the risk of operational errors. Precision in Downhole Settings: Guarantees the accurate placement of bridge plugs and cement retainers for improved well performance. Durability Under Pressure: Built to endure the rigorous conditions of downhole operations, offering lasting performance. The SST Hydraulic Setting Tool by Marlin Oil Tools represents the cutting edge in downhole mechanical solutions, providing operators with a powerful tool for enhancing well completion and intervention outcomes. Incorporate the SST into your operations to ensure efficient, accurate, and reliable downhole equipment setting.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Coiled Tubing Sliding Sleeve Activator

SSA Sliding SLeeve Actuator![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SSA (Sliding Sleeve Actuator) from Marlin Oil Tools: Revolutionizing Multistage Fracturing Operations Marlin Oil Tools proudly presents the SSA (Sliding Sleeve Actuator), a state-of-the-art downhole tool designed to optimize well intervention and multistage fracturing operations. Engineered to activate sliding sleeves with unparalleled efficiency and precision, the SSA is an essential tool for modern well completion strategies. By eliminating the need for traditional activation balls, the SSA streamlines fracturing operations, significantly reducing intervention times and enhancing overall well productivity. Key Features of the SSA (Sliding Sleeve Actuator): Efficient Sleeve Activation: The SSA is specifically designed to activate sliding sleeves in the liner of the well, targeting planned fracturing spots with accuracy. Simplifies Operations: Replaces the conventional method of dropping activation balls into the well, thereby simplifying the activation process. Rapid Deployment and Retrieval: Engineered for use with coil tubing, the SSA ensures quick deployment and retrieval, minimizing downtime in fracturing operations. Eliminates Milling or Catching: By using the SSA, the need to mill or catch activation balls post-fracturing is removed, enhancing operational safety and efficiency. Seamless Integration: Optimally designed to integrate with existing well completion setups, the SSA facilitates a smooth fracturing process. Precision in Fracturing: Offers precise control over the activation of sliding sleeves, ensuring effective multistage fracturing exactly where needed. Elevate your well intervention and fracturing operations with the SSA (Sliding Sleeve Actuator) from Marlin Oil Tools, a groundbreaking solution tailored for the oil and gas industry. This innovative downhole tool revolutionizes sliding sleeve activation during multistage fracturing, offering a more efficient and precise alternative to traditional activation balls. Designed for rapid deployment and retrieval via coil tubing, the SSA not only simplifies fracturing operations but also significantly enhances well productivity and safety. Choose the SSA for a streamlined, effective approach to modern well completions and fracturing. Why Choose the SSA from Marlin Oil Tools? Operational Efficiency: Dramatically reduces intervention times, allowing for faster and more efficient fracturing operations. Enhanced Safety and Simplicity: Removes the complexities and safety concerns associated with milling or catching traditional activation balls. Precision Activation: Ensures accurate activation of sliding sleeves, maximizing the effectiveness of multistage fracturing. Innovative Design: The SSA's design is optimized for ease of use with coil tubing, ensuring seamless operation and integration into fracturing workflows. The SSA (Sliding Sleeve Actuator) by Marlin Oil Tools represents the forefront of innovation in downhole tools, providing operators with an advanced solution to meet the challenges of today's fracturing operations. Incorporate the SSA into your well intervention toolkit to achieve superior efficiency, safety, and performance in multistage fracturing.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the JWN Jet Wash Nozzle from Marlin Oil Tools: A Revolution in Well Intervention and Perforation Technology Marlin Oil Tools is proud to unveil the JWN Jet Wash Nozzle, an advanced downhole tool specifically engineered for precision well intervention and perforation tasks. As a critical component of the Bottom Hole Assembly (BHA), the JWN Jet Wash Nozzle is designed to enhance the efficiency of perforating casing or tubing by utilizing a high-speed jet of a gel-sand mixture directed at the well's inner casing wall. Here’s why the JWN Jet Wash Nozzle is a game-changer in the oil and gas industry. Key Features of the JWN Jet Wash Nozzle: Precision Perforation: The JWN Jet Wash Nozzle delivers a high-velocity jet stream of a gel-sand mixture, enabling precise and efficient perforation of the casing or tubing. Abrasive-Resistant Materials: Constructed from materials that resist wear from abrasive particles, ensuring longevity and reliability under harsh downhole conditions. Versatile Design Options: Available in a basic design for continuous circulation or a ball-activated design that opens nozzles only after a ball drop, providing flexibility for specific operational needs. Enhanced Well Productivity: By performing abrasive cuts through metal, cement, and part of the surrounding rock, the JWN enhances well connectivity and productivity. Seamless BHA Integration: Designed to run in hole as part of the BHA alongside other downhole tools, the JWN Jet Wash Nozzle is compatible with a wide range of well intervention equipment. Elevate your well intervention and perforation operations with the JWN Jet Wash Nozzle from Marlin Oil Tools, a leading-edge solution designed for optimal efficiency and precision in the oil and gas sector. Featuring abrasive-resistant nozzles and a high-speed gel-sand mixture jet, the JWN Jet Wash Nozzle precisely perforates casing and tubing, improving well productivity. With options for continuous circulation or ball-activated operation, this tool offers unparalleled flexibility and durability for your well intervention needs. Choose the JWN Jet Wash Nozzle for a reliable, efficient, and versatile solution in enhancing well connectivity and output. Why Choose the JWN Jet Wash Nozzle from Marlin Oil Tools? Targeted Perforation: Achieves precise perforation for improved fluid flow and well performance. Durable Construction: Built to withstand the rigors of abrasive materials, ensuring tool integrity and operational longevity. Operational Flexibility: Adapts to various well intervention scenarios with basic and ball-activated designs. Improved Efficiency: Reduces downtime and enhances well productivity through efficient and effective perforation. The JWN Jet Wash Nozzle by Marlin Oil Tools represents the pinnacle of well intervention technology, providing operators with a powerful tool for enhancing well integrity and performance. Incorporate the JWN Jet Wash Nozzle into your operations to achieve superior results in well perforation and intervention tasks.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Fixed Blade Stabilizer for Coiled Tubing

FBS Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the FBS (Fixed Blade Stabilizer) from Marlin Oil Tools: The Optimal Solution for Coiled Tubing Stability in Oil and Gas Well Interventions Marlin Oil Tools proudly presents the FBS (Fixed Blade Stabilizer), a cutting-edge downhole tool meticulously designed to enhance the stability and efficiency of well intervention operations. As part of the borehole assembly (BHA), the FBS plays a crucial role in centering the BHA relative to the well's axis, ensuring optimal performance during critical interventions, especially in wells with significant inclination or when coiled tubing (CT) exhibits residual bending. Here’s why the FBS is an indispensable tool for your operations. Key Features of the FBS (Fixed Blade Stabilizer): Precision Centering: Engineered to center the BHA within the well, the FBS ensures that tools like mills or perforators operate effectively at the heart of the wellbore, crucial for tasks requiring precise positioning such as milling or perforation. Versatile Application: Ideal for use in wells with various inclinations, up to 90 degrees, where the BHA tends to lie against the well wall, the FBS provides the necessary support to maintain the BHA in the optimal position. Enhanced Stability: By preventing the eccentric location of the CT BHA within the well, the FBS significantly reduces the risk of operational issues, ensuring smoother, more efficient well interventions. Robust Design: The fixed blades of the FBS are designed to withstand the harsh downhole conditions, offering durability and reliability throughout the operation. Elevate your well intervention strategies with the FBS (Fixed Blade Stabilizer) from Marlin Oil Tools, a premier downhole tool designed for maximum BHA stability and efficiency in oil and gas operations. The FBS excels in centering the BHA relative to the well's axis, ensuring accurate positioning for milling, perforation, and other precision-dependent tasks. With its ability to accommodate wells of up to 90 degrees inclination and correct CT BHA eccentricity, the FBS is your solution for enhancing operational effectiveness and reducing risks in challenging well conditions. Choose the FBS for unparalleled support and stability in your coiled tubing operations. Why Choose the FBS from Marlin Oil Tools? Optimized Well Intervention: Improves the accuracy and efficiency of milling and perforation tasks by centering the BHA. Adaptable to Various Well Inclinations: Provides consistent performance in wells with up to 90 degrees of inclination. Reliable Stability: Reduces operational complications by preventing the CT BHA from lying eccentrically in the well. Durable Construction: Built to endure the rigors of downhole environments, ensuring longevity and reliability. The FBS (Fixed Blade Stabilizer) by Marlin Oil Tools represents the forefront of downhole stabilization technology, ensuring that your well intervention operations are performed with the highest level of precision and efficiency. Incorporate the FBS into your coiled tubing operations to achieve optimal outcomes in well stability and intervention success.

Buy

Made to Order

Manufacturer

New

API

Land Freight

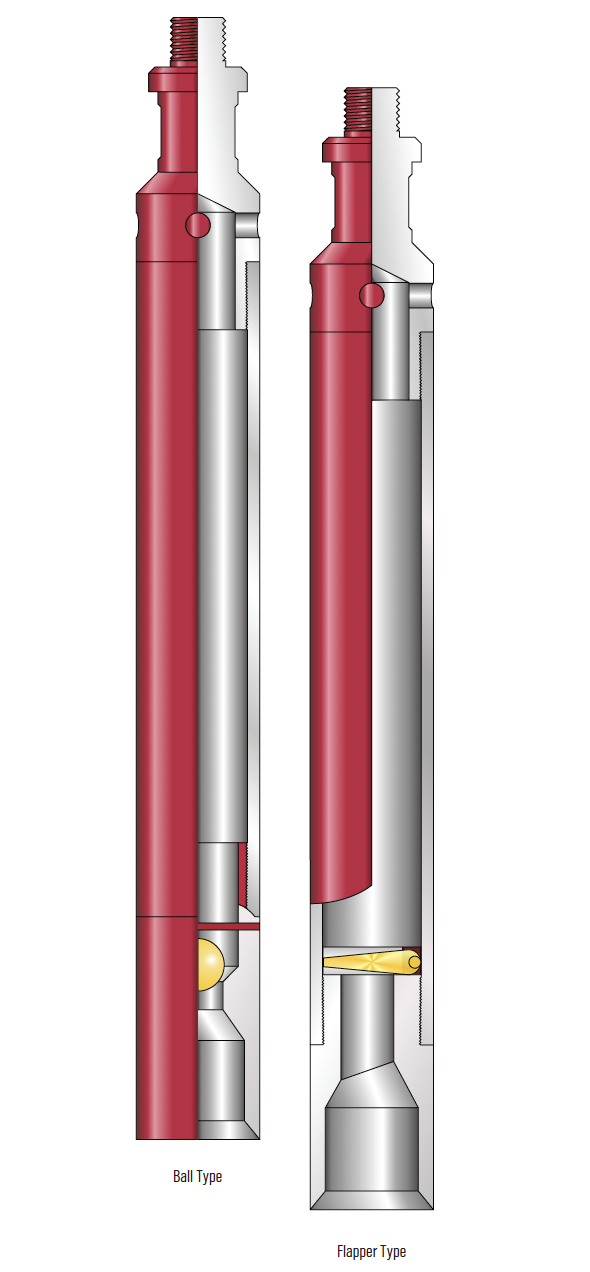

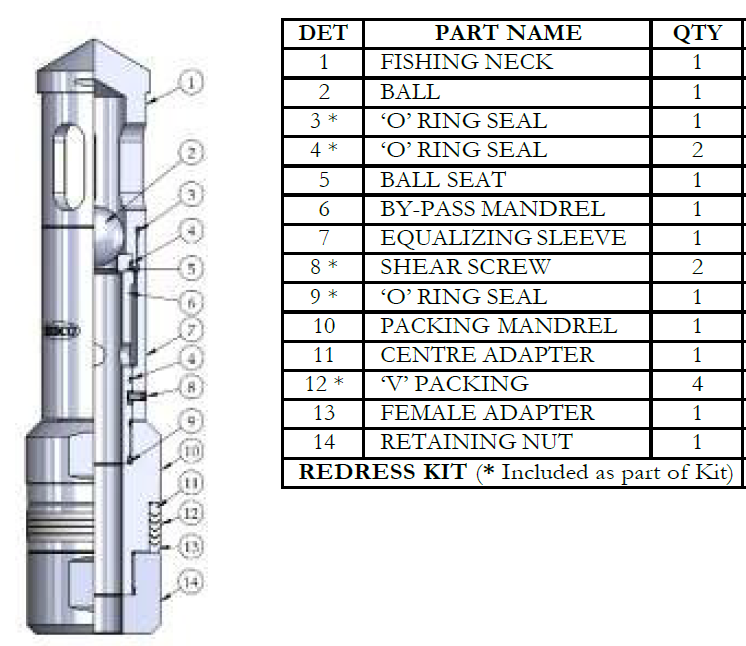

Introducing the JKM Junk Mill from Marlin Oil Tools: The Ultimate Downhole Tool for Efficient Well Intervention and Milling Operations Marlin Oil Tools proudly presents the JKM Junk Mill, a premier downhole tool designed to optimize well intervention jobs by efficiently grinding and removing unwanted objects from the wellbore. Whether you're dealing with intentionally placed equipment such as bridge plugs or facing challenges with emergency lost equipment, the JKM Junk Mill is engineered to handle a variety of downhole obstacles with unmatched efficiency. Key Features of the JKM Junk Mill: Superior Milling Performance: Capable of grinding and washing out any object softer than the mill's cutters, ensuring clean and clear wellbores. Effective Debris Removal: Features multiple flushing holes for drilling fluid circulation, efficiently removing milled particles and cooling the cutting edge. Durable Carbide Construction: Equipped with carbide welded onto the body for robust milling action, available in crushed carbide and various insert designs to suit different milling needs. Customizable Milling Solutions: Offers a range of carbide welding designs including flat, concave, and convex bottoms, as well as top and side carbide surfacing, providing versatility for specific well intervention requirements. Extended Service Life: The durability of the carbide elements depends on the milling conditions, with Marlin Oil Tools providing redress services for worn carbide to ensure continued high performance. Powered by Downhole Motors: Rotation of the mill is performed by a downhole motor, enhancing milling efficiency and effectiveness. Elevate your well intervention strategies with the JKM Junk Mill from Marlin Oil Tools, a cutting-edge solution designed for the efficient removal of downhole obstacles in the oil and gas industry. Featuring advanced milling capabilities, effective debris removal, and durable carbide construction, the JKM Junk Mill ensures your wellbore is free from unwanted materials, enhancing operational efficiency and well productivity. With customizable carbide designs and comprehensive redress services, Marlin Oil Tools provides a versatile and reliable tool for tackling a wide range of milling challenges. Choose the JKM Junk Mill for its superior performance, durability, and adaptability, making it an essential component of your well intervention toolkit. Why Choose the JKM Junk Mill from Marlin Oil Tools? Enhanced Milling Efficiency: Delivers unparalleled performance in grinding down and removing wellbore obstructions. Versatile Application: Adaptable to various well intervention scenarios, from routine cleanouts to emergency equipment retrieval. Long-Term Durability: Constructed with high-quality carbide for extended tool life, even in the most challenging milling operations. Tailored to Your Needs: Offers customization options to match your specific well intervention requirements, maximizing tool effectiveness. The JKM Junk Mill by Marlin Oil Tools represents the forefront of downhole milling technology, offering oil and gas operators a powerful solution for enhancing well intervention outcomes. Incorporate the JKM Junk Mill into your operations for smoother, more effective wellbore preparation and obstacle management.

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The FXE wireline-retrievable flapper valve, which is normally closed, is held open by hydraulic control pressure from the surface. The valve operates on a hydraulic piston principle. To open, hydraulic pressure slightly higher than the well pressure is applied to move the piston downward. This pressure unseats the secondary seat, allowing pressure to enter through equalizing ports. Then, as additional hydraulic pressure is applied to the piston, it continues downward movement, pushing the flapper open. The flapper hinge assembly is designed such that the force on the piston is not applied directly on the hinge pin. Upon loss of hydraulic pressure in the control line, the valve’s large spring serves to lift the hydrostatic head of the control fluid. The flapper spring is designed to close the valve when the piston moves up past the flapper. Opening Prong Nose Seal The FXE valve uses the valve housing as the downstop for the opening prong. This metal-to-metal (MTM) interface is designed to prevent flow from passing between the valve housing and the opening prong. The MTM interface isolates the flapper and seat from fluid flow while the valve is open. This design creates an MTM interface with the full force exerted by the hydraulic piston, minus the spring compression force, holding the two metal faces in contact. Radius of Curvature at Flow Entrance Halliburton conducted a study with various curvatures on the entrance to the valve. The study tested abrasive fluids flowing through different test subs and examined the resulting wear patterns. As a result, an optimum radius of curvature was determined and implemented on the valve housings of all wireline-retrievable safety valves. Applications » General production completions Features » Equalizing-type flapper closure » Solid construction flapper made from bar stock » Spherical radius seat on flapper improves seal reliability » Sealing and seating surfaces are out of the well production flow path when valve is in the open position *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

Rod Pump of various diameters and stroke lengths to optimize oil production

Rod Pump![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

Sucker rod pumping systems are the oldest and most widely used type of artificial lifting system for oil wells. Sucker-rod pumping is the most widely used artificial lift method for onshore oil wells. Sucker-rod strings transfer the motion from the driving machine on the wellhead to the downhole oil pump. Pump diagnoses are generally conducted through an interpretation of the pump dynamometer graph (pump card).

Buy

Made to Order

Product

New

API

Sea Freight

DeltaV Backbone Infrastructure

![]() Nulux Networks in Edmonton

Nulux Networks in Edmonton

Navigating Through the Digital Veins of the Oil and Gas Industry: Introducing DeltaV Backbone Infrastructure by Nulux Network Solutions In the ever-evolving arena of the oil and gas industry, where massive volumes of data traverse through the intricate digital veins of complex operational networks, the prowess of a robust, secure, and efficient backbone infrastructure stands undisputed. At Nulux Network Solutions, we comprehend the pulse of this digital heartbeat, presenting a bespoke service for engineering professionals in the sector: The DeltaV Backbone Infrastructure. A Symphony of Sustainable Solutions: Lighting the Path with Fiber Optics In an era where sustainability intertwines with technological advancements, Nulux unfurls a spectrum of products, solutions, and services across the comprehensive energy value chain. Endeavoring to illuminate your journey toward a sustainable future, our Fiber Optic solutions embody the quintessence of high-speed, reliable, and secure data transmission across your operational ecosystems, ensuring that your digital operations move with an unparalleled rhythm of coherence and efficiency. The DeltaV Backbone Infrastructure: Navigating through the Digital Nexus Our DeltaV Backbone Infrastructure is not merely a service but an orchestrated amalgamation of technology, expertise, and reliability, ensuring your operations in the oil and gas sectors are streamlined, secure, and synergistically attuned to the digital transformations permeating the industry. Robust Data Transmission: Ensuring that your operational data, ranging from real-time analytics to predictive maintenance insights, traverse securely and efficiently across the digital pathways. Enhanced Reliability: With a fiber-optic backbone, experience a network with minimal downtime and robust resistance against physical wear and tear, providing a perennial flow of vital operational data. Scalable Solutions: As your operations expand, so does our DeltaV Backbone Infrastructure, ensuring that your growing data demands are met with equal vigor and capacity. Intricate Weaving of Data and Operations The DeltaV Backbone Infrastructure meticulously intertwines with your operational nodes, ensuring that the massive data generated at every point is seamlessly integrated, analyzed, and utilized, providing a foundation upon which strategic decisions can be formulated and executed with precision. Safeguarding your Digital Pathways Ensuring that your data pathways are not just operationally optimized but also securely fortified, the DeltaV Backbone Infrastructure is built upon stringent security protocols, ensuring a secure digital environment wherein your data is shielded against potential cyber vulnerabilities. Embark on a Journey with Nulux Traverse through the digital corridors of the oil and gas industry with Nulux Network Solutions, where your data is not merely transmitted but is secured, analyzed, and utilized to sculpt a future where your operations resonate with sustainability, efficiency, and innovative prowess. With the DeltaV Backbone Infrastructure, you navigate through a digital nexus, where every byte of data, every decision and every operational stride is backed by the robust reliability, unparalleled speed, and secure pathways of our state-of-the-art fiber-optic solutions. Ensuring a Future where Data Drives Decision In an operational universe where data is the catalyst for decisions, ensuring its secure, reliable, and efficient transmission becomes paramount. Navigate with Nulux, where your data doesn’t just traverse; it drives your operations towards a future where every decision is data-driven, every operation is efficient, and where your journey towards sustainability is always illuminated by the reliable glow of our solutions. Your journey through the digital and operational landscapes of the oil and gas industry begins with Nulux – where your data finds its true pathway, and where your operations find their true rhythm. Let's sculpt a future, together, navigating through the digital veins of innovation, sustainability, and operational excellence.

Service

In Stock

Service

New

ISO

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The WL™packer is a new wireline-set, retrievable, high-performance production packer, run in combination with the L-10 on/off tool. The WL can be run as a temporary bridge plug by installing a blanking plug in the L-10 seal nipple, above the packer. This enables remedial or stimulation work above the packer. The plug can then be removed with conventional wireline methods, allowing production of the well to be resumed.

Buy

Made to Order

Product

New

API

Sea Freight

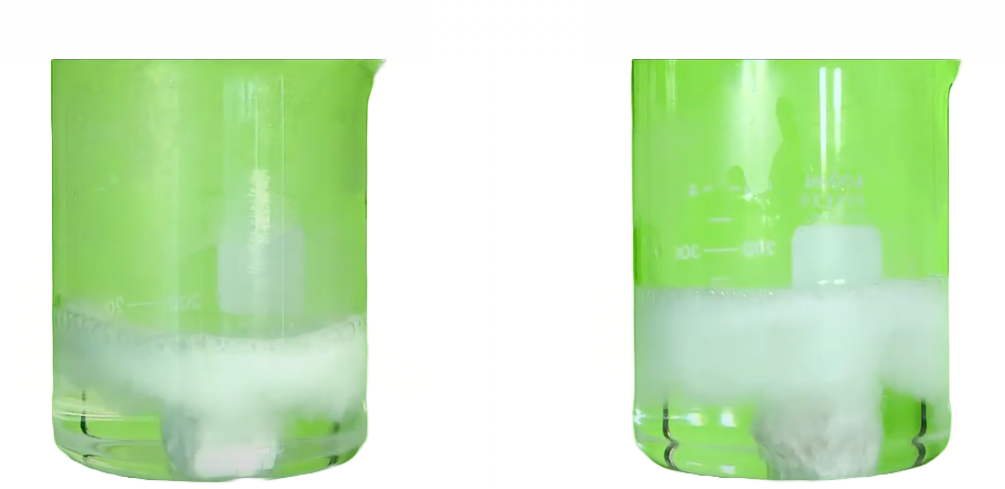

![]() Cleanstream B.V. in Ter Apel

Cleanstream B.V. in Ter Apel

Introducing HCR-6000, the latest addition to Cleanstream's ‘Environmentally Responsible’ modified acid product line. HCR-6000 is a powerful, low fuming Modified acid that has solubilizing abilities of 15%-25% HCI (concentrate). It's the perfect solution for minimizing the hazardous exposure levels and fuming properties of Hydrochloric acid. HCR-6000 is specifically designed to cater to the needs of the oil and gas industry, where the use of mineral acids is common practice. But unlike traditional hydrochloric acid, HCR-6000 is a clear, low-fuming acid with a low vapor pressure. This means that it poses less of a risk to human health and the environment. One of the standout features of HCR-6000 is its comprehensive spending nature. It is more than two times slower to spend than conventional HCl acid, making it an economical choice for your operations. And if that's not enough, HCR-6000 is also classed as a Class 1 acid package, making it easy to transport and handle. HCR-6000 is also highly customizable. It can be enhanced with conventional oilfield chemistry to cater to the specific needs of your operations. It offers high thermal stability, no precipitation from spent fluids, and iron stabilization effect (nano particles), making it a versatile solution for various applications such as spearhead acid, fracturing/matrix, production, injection wells, and scale treatment. HCR-6000 is also oil compatible, making it an excellent choice for your oil and gas production. Its high spent pH of over 4.5 makes it easy to dispose of, reducing plant interruptions and making it an environmentally responsible choice. At Cleanstream, we are committed to providing our customers with the best possible solutions that are both environmentally responsible and efficient. With HCR-6000, we are taking another step towards a cleaner and safer future for the oil and gas industry. Contact us today to learn more about HCR-6000 and our other ‘Environmentally Responsible’ products.

Buy

In Stock

Manufacturer

New

ISO

Land Freight

![]() AMS Hydro in Vancouver

AMS Hydro in Vancouver

A SIMPLE WATER-TO-WIRE SOLUTION This micro hydro solution is based on both proprietary designs in the turbine and drivetrain, and off-the-shelf components, to deliver a complete water-to-wire system. This solution is a self-contained module made of single or twin turbines, generators, electrical cabinet, and is connectable to BOP/Grid. They are assembled and mounted in a self-stabilized concrete structure requiring no civil works. The system power output is 480 V, 3-phase AC, 50 Hz & 60 Hz. This new, highly cost-effective, renewable energy solution, capable of capturing most of the untapped energy on your site, has many assets. Its performance levels have been tested both in laboratory and on site. Actual power rating and instantaneous output depend mainly on water velocity (>1 m/s). In our catalogue of product, we can select the best options to suit a particular site. This technology is scalable by equipping an existing canal with dozens or hundreds of 5 to 15 kw modules. Land usage Turbines are installed on existing, untapped water infrastructures. No land planning is needed, with no modification required on existing assets. Predictable and available Permanent, predictable and controllable production with 95% availability. *information from manufacturer

Buy

Made to Order

Product

New

ASTM

Land Freight

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The T, T-CL, C-SRL-CL and CXS Tubing Hangers are all single completion, mandrel-type hangers for use in either the C Tubing Spool or the CD-2 Tubing Spool. T Tubing Hanger The T Tubing Hanger withstands stress of high pressure, corrosive/erosive elements associated with well flow. Its flexible neck maintains the metal seal despite thermal or pressure cycling. T-CL Tubing Hanger The T-CL Tubing Hanger withstands stress of high pressure, corrosive/erosive elements associated with well flow. A control line exit block is available in either a bull plug style or block needle valve style. C-SRL-CL Tubing Hanger The C-SRL-CL Tubing Hanger incorporates a pressure energized SRL neck seal which accommodates vertical movement in the tubing hanger during BOP testing. A control line exit block is available in either a bull plug style or block needle valve style. The C-SRL-CL hanger should be used in 7-1/16” 10,000 psi Type C Tubing Spools. CXS Tubing Hanger The CXS Tubing Hanger includes two neck seals which may be used to isolate one control line.

Buy

In Stock

Product

Used

API

Air Freight

![]() PipeDNA in Houston

PipeDNA in Houston

Streamlining OCTG Tubular Goods Management with PipeDNA: Boosting Efficiency and Reliability Efficient management of OCTG (Oil Country Tubular Goods) is critical in the oil and gas industry to ensure the success of drilling and production operations. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage their OCTG tubular goods, increase visibility, and optimize their operations for enhanced efficiency and reliability. Comprehensive Inventory Management and Tracking: PipeDNA offers a comprehensive inventory management and tracking system specifically tailored for OCTG tubular goods. Gain full visibility into your OCTG inventory, including utilization, activity, and trends. By monitoring the status and location of each OCTG pipe, stakeholders can proactively plan for upcoming drilling projects, streamline logistics, and optimize inventory levels. PipeDNA enables accurate tracking, reducing the risk of stockouts, minimizing downtime, and maximizing operational efficiency. Efficient Logistics Management: With PipeDNA, stakeholders can efficiently manage all aspects of logistics operations related to OCTG tubular goods. From shipments to status tracking and documentation, PipeDNA simplifies the entire process, ensuring seamless coordination across multiple locations and parties involved. Furthermore, the platform facilitates pipe bundling, enabling stakeholders to optimize transportation and storage, minimizing costs and improving overall efficiency. Streamlined Inspection Management: PipeDNA's inspection management feature provides a centralized platform to manage inspection jobs for OCTG tubular goods across multiple sites. With real-time tracking and status updates, stakeholders can monitor the progress of inspection jobs, ensuring timely completion and adherence to quality standards. Additionally, the platform enables the management of inspection profiles, allowing for efficient scheduling, tracking, and reporting of inspection activities. Automated Tally Operations: Pipe tallying is a crucial process in OCTG tubular goods management, and PipeDNA simplifies this operation with automated tally operations. Stakeholders can create and manage tally operations within the platform, streamlining the process and eliminating manual calculations. By automating pipe tally jobs and workflows, PipeDNA saves time, reduces errors, and ensures accurate and up-to-date tally results, enhancing overall operational efficiency. Enhanced Identification and Traceability: PipeDNA offers quick and accurate identification of OCTG tubular goods, providing stakeholders with essential pipe details, activity history, and traceability documentation. With seamless integration of popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables easy identification and tracking of each pipe, ensuring precise inventory control and reducing the risk of misplaced or misused OCTG tubular goods. This enhanced traceability minimizes downtime and improves resource allocation. Designed for the Oil and Gas Industry: PipeDNA was specifically designed for stakeholders across drilling, manufacturing, and oilfield services, catering to their unique needs in OCTG tubular goods management. Whether you are a drilling contractor, oilfield rental company, oilfield and inspection service provider, steel pipe manufacturer, or pipe distribution and storage provider, PipeDNA offers tailored solutions to streamline your OCTG operations and drive efficiency. Leveraging Emerging Technologies: At its core, PipeDNA harnesses the power of today's emerging technologies to optimize OCTG tubular goods management processes. The platform seamlessly integrates with popular barcode standards, such as UPC, EAN, and QR codes, enabling efficient barcoding and labeling. Moreover, PipeDNA is RFID ready, supporting the integration of RFID technologies for accurate asset tracking. The platform also facilitates IoT data integration using the MQTT standard, enabling fast and reliable sensor data integration for enhanced decision-making. PipeDNA revolutionizes OCTG tubular goods management in the oil and gas industry, providing a smart cloud-based platform that enhances efficiency, reliability, and visibility. With its comprehensive inventory management, streamlined logistics operations, automated tallying, and robust identification and traceability features, PipeDNA empowers stakeholders to optimize their OCTG operations and make informed decisions based on real-time data. Leverage the power of PipeDNA and take your OCTG tubular goods management to new heights of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

Bearings are "parts that assist objects' rotation". They support the shaft that rotates inside the machinery. Machines that use bearings include automobiles, airplanes, electric generators and so on.

Buy

Made to Order

Product

New

ISO

Sea Freight

Circulating Type Chokes for Nipples

Downhole Tools![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

HOCA Oil Tools: Mastering Flow Control with Circulating Type Chokes for Nipples In the specialized field of downhole operations, mastering the control of fluid flow within the wellbore is critical for operational success and efficiency. HOCA Oil Tools is at the forefront of this challenge, offering advanced solutions with our Circulating Type Chokes for Nipples. Designed to integrate seamlessly with landing nipples in the wellbore, these tools are essential for precise flow control and well management during various downhole activities. HOCA’s Circulating Type Chokes for Nipples: Precision Engineered for Optimal Flow Control Our Circulating Type Chokes for Nipples are designed for operators seeking to maintain precise control over fluid flow in their downhole operations. Whether for circulation, testing, or intervention tasks, our chokes provide the versatility and reliability needed in today’s diverse well environments. Constructed with the highest quality materials and engineered to withstand harsh downhole conditions, HOCA’s chokes ensure optimal performance and durability. Experience the HOCA Oil Tools Difference Choosing HOCA Oil Tools’ Circulating Type Chokes for Nipples means opting for a solution that embodies innovation, quality, and operational excellence. Our commitment to providing cutting-edge downhole solutions ensures that our products meet the complex demands of modern oil and gas operations, delivering performance that exceeds expectations. Incorporating our Circulating Type Chokes into your downhole toolkit signifies a step toward enhanced operational control, efficiency, and safety. With HOCA Oil Tools, you gain not just a supplier but a dedicated partner committed to supporting your downhole challenges with advanced solutions and expert service. Opt for HOCA Oil Tools for your downhole needs and unlock the full potential of your operations with our Circulating Type Chokes for Nipples. Partner with us, and elevate your downhole flow control to new levels of precision and reliability. With HOCA Oil Tools, enhance your downhole operations with tools that redefine efficiency, safety, and performance in the demanding oil and gas industry.

Buy

In Stock

Product & Service

New

API

Air Freight

Storm Choke WI Valve 3.97 inch

Water Injection Valve![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

Partnered with Microsoft Business Voice

Cybersecurity![]() ALCiT in Mississauga

ALCiT in Mississauga

Elevate Your Communications with ALCiT's Microsoft 365 Business Voice Partnership In the world of innovation, one name shines brighter than the rest: Microsoft. Since its inception in 1975, Microsoft has been synonymous with technological prowess, transforming the landscape of modern business. ALCiT proudly joins forces with Microsoft 365 Business Voice, introducing a cloud-based, integrated phone system that redefines how you communicate, collaborate, and connect. Microsoft: A Legacy of Innovation Microsoft's legacy is etched in innovation. For decades, they've sculpted the digital future, revolutionizing industries and empowering businesses. ALCiT is thrilled to be a part of this legacy, bringing you Microsoft 365 Business Voice – a solution that transcends communication barriers. Resource Unification, Powered by the Cloud Imagine a realm where your resources converge seamlessly. With Microsoft 365 Business Voice, you can bid adieu to scattered communication tools. This cloud-based, integrated phone system places your entire arsenal in one place, fostering collaboration and calling no matter where you work. Effortless Communication, Elevated Flexibility ALCiT's Microsoft 365 Business Voice empowers you in two pivotal ways: Customer Connection Amplified: Responding to customers becomes a breeze, with unmatched ease and flexibility. Answering the phone transforms from a task into a seamless interaction. Infinite Collaboration: Breaking boundaries within your team and business is no longer a challenge. Seamlessly communicate, collaborate, and create, regardless of physical barriers. Grow with Confidence Designed with small-to-medium businesses in mind, Microsoft 365 Business Voice is your compass to growth. ALCiT's partnership ensures that the system is not just a tool, but an engine of expansion, enabling businesses to rise to new heights. Shape the Future of Communication Today ALCiT's Microsoft 365 Business Voice partnership redefines communication. Experience the cloud-based revolution that connects you with your customers, your team, and your growth journey. Experience the power of ALCiT's partnership with Microsoft 365 Business Voice.

Service

Made to Order

Service

New

ISO

Knuckle Joint for Wireline Toolstring

Knuckle Joint![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer