Gas Check Valve for LM2500 Gas Turbine

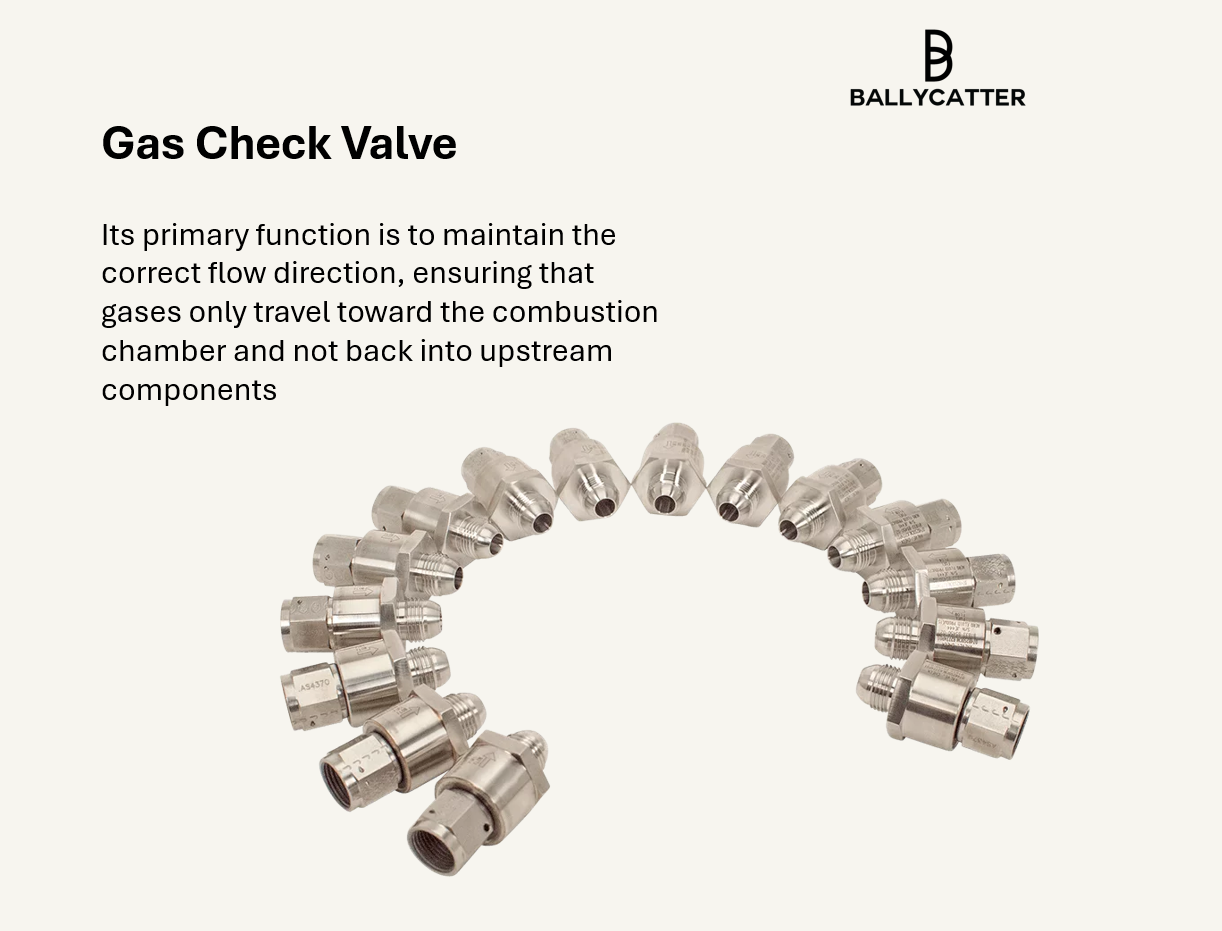

Gas Check Valve

Also known as:

Check Valve, Reflux Valve, Retention Valve

Gas Check Valve for LM2500 Gas Turbine

Gas Check Valve

Also known as:

Check Valve, Reflux Valve, Retention ValveBuy

Made to Order

Product

Price:

Request for QuoteShipping:

Air freightNote:

The gas check valve is used in LM2500 gas turbines to prevent combustion gases from flowing back into oil or fuel lines.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The Gas Check Valve is used in LM2500 gas turbines to control flow direction within fuel and oil systems. It prevents combustion gases from flowing backward into lines where reverse flow could compromise system performance or safety. This one-way valve supports reliable turbine operation, particularly in high-demand environments like oil and gas or power generation, where maintaining proper flow direction is essential to protect components and ensure consistent functionality.

Technical Specifications

| Part Number | L62774P02 |

| Valve Type | Gas check valve |

| Power Requirement | Passive (no external actuation required) |

| Turbine Compatibility | LM2500 aero-derivative gas turbines |

Features and Benefits

- One-way (non-return) design.

- Compact size.

- Engineered for LM2500.

- Improves turbine safety.

- High-temperature compatibility.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The Gas Check Valve is a unidirectional valve used in LM2500 gas turbine systems to prevent the reverse flow of combustion gases into critical fuel and oil lines. Its primary function is to maintain the correct flow direction, ensuring that gases only travel toward the combustion chamber and not back into upstream components, where reverse flow could cause damage, safety risks, or system inefficiencies.

This check valve is engineered to operate under the high-pressure and high-temperature conditions typical of industrial gas turbine environments. It serves as a passive safety component, requiring no external power to function, and contributes to the overall reliability and integrity of the turbine system.

Commonly found in aero-derivative gas turbines used in oil and gas applications, the check valve is essential for maintaining proper system performance. Its inclusion in the turbine’s gas path helps ensure safe operation by minimizing the risk of combustion gas contamination in auxiliary systems.

Engineering Data