Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

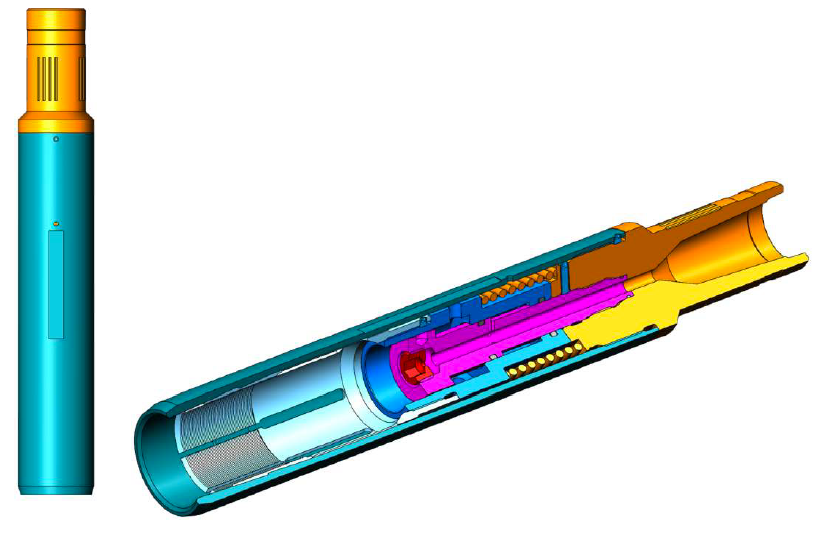

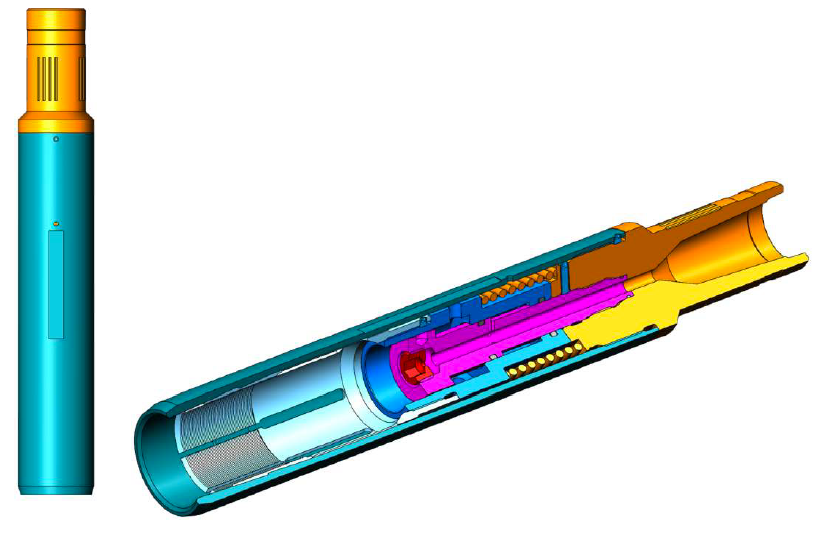

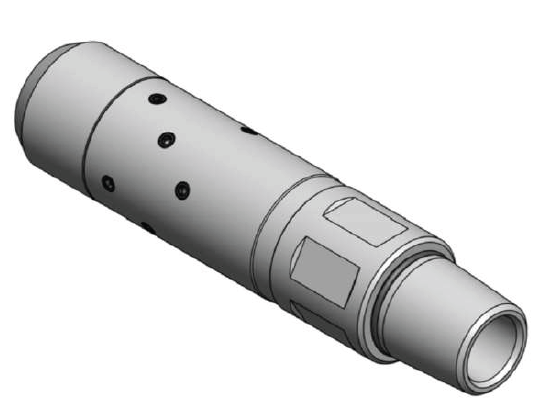

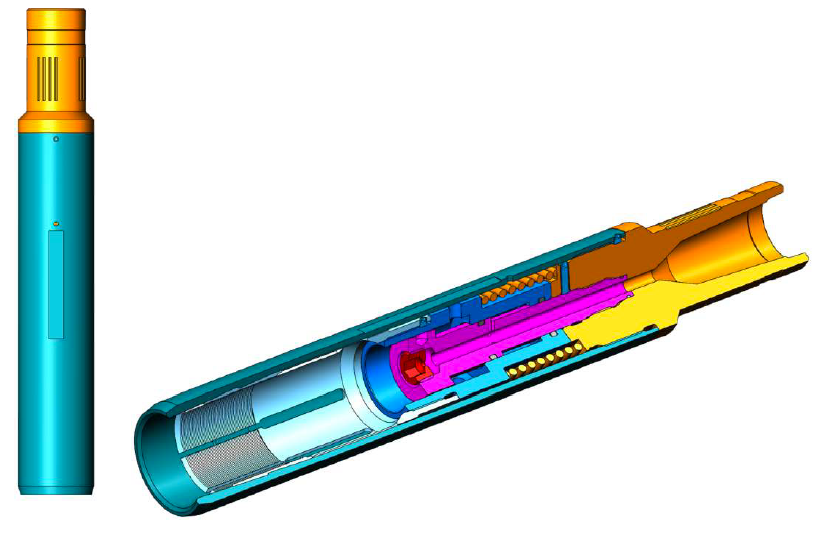

FRO Coiled Tubing Tool

Also known as:

Coiled Tubing Downhole ToolBuy

Made to Order

Manufacturer

New

API

Land Freight

Title:

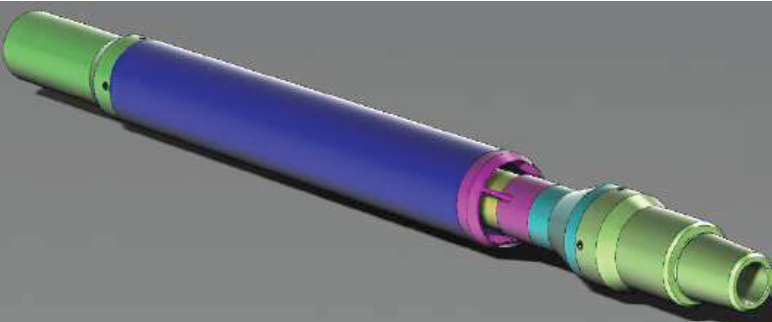

Flow Release Overshot for Coiled TubingModel Number:

FRO-69-01.1Availability:

Made to OrderDelivery Time (weeks):

2 - 4 WeeksIn Stock

Transaction Type

BuyCondition

NewWeight

Based on Specs lbsLocation

CanadaCompany Type

ManufacturerQuality Assurance

APIPrice

Request for QuoteMaterial

SteelBrand Name

Marlin Oil ToolsShipping

Land FreightNotes

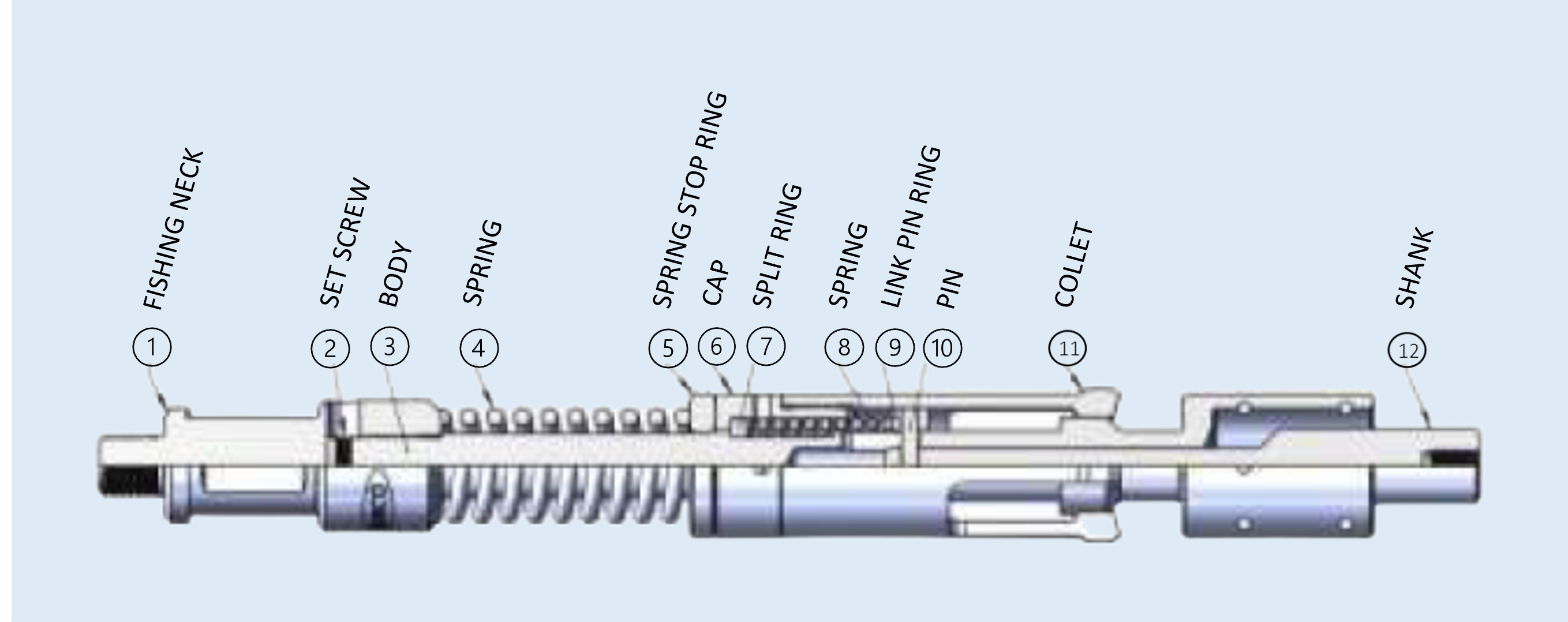

This is a downhole tool used well intervention for fishing operations. The overshot has a replaceable collet to catch a smooth surface. The collet covers a range of fish outer diameters from 1.0” to 2-1/8”

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the TPM Tapered Mill from Marlin Oil Tools: The Essential Downhole Tool for Precision Well Intervention Marlin Oil Tools is proud to offer the TPM Tapered Mill, a specialized downhole tool crafted for superior performance in well intervention tasks. Designed to navigate and resolve wellbore challenges efficiently, the TPM Tapered Mill excels in grinding and washing out objects that are softer than the mill's cutters, from intentionally placed equipment like bridge plugs to unexpectedly lost tools. Key Features of the TPM Tapered Mill: Versatile Milling Capabilities: Engineered to remove a wide array of downhole obstructions, ensuring a clear path for well operations. Optimized Debris Removal: Equipped with multiple flushing holes, the TPM facilitates the circulation of drilling fluid, efficiently clearing milled particles from the well and cooling the cutting edge. Durable Carbide Construction: Features a robust body with carbide welded on, available in crushed carbide and various insert designs to match milling requirements against different materials. Customizable Geometry: The tapered design is tailored to enhance the ID of wellbore restrictions, with customizable geometry including the length of the cone, minimal OD, and maximal OD based on client specifications. Extended Service Life: The longevity of the carbide components is maximized through optimal milling modes and can be further extended with Marlin Oil Tools' comprehensive redress services for worn carbide. Powered by Downhole Motors: Rotation facilitated by a downhole motor enhances the milling efficiency, making the TPM an integral part of the well intervention toolkit. Elevate your well intervention operations with the TPM Tapered Mill from Marlin Oil Tools, a leading-edge solution designed for the efficient removal of downhole obstructions in the oil and gas industry. This downhole tool combines advanced milling technology with a tapered design to effectively increase the ID of wellbore restrictions, ensuring operational success. With its durable construction, customizable geometry, and optimized debris removal capabilities, the TPM Tapered Mill is essential for achieving a clear and operational wellbore. Whether addressing emergency lost equipment or routine well maintenance, the TPM Tapered Mill offers precision, efficiency, and reliability. Trust Marlin Oil Tools for your well intervention needs and experience unparalleled performance and service life with the TPM Tapered Mill. Why Choose the TPM Tapered Mill from Marlin Oil Tools? Precision Milling: Delivers unmatched efficiency in grinding down and removing wellbore obstructions. Customization to Fit Operational Needs: Offers tailored solutions to meet specific well intervention challenges. Robust and Reliable: Built to withstand the harsh downhole environment and ensure prolonged tool effectiveness. Expert Support and Services: Backed by Marlin Oil Tools' commitment to quality and customer support, including redress services for extended tool life. The TPM Tapered Mill by Marlin Oil Tools represents the pinnacle of downhole milling innovation, providing a versatile, durable, and efficient solution for well intervention and maintenance operations. Incorporate the TPM Tapered Mill into your toolkit for smoother, more effective well interventions.

Buy

Made to Order

Manufacturer

New

API

Land Freight

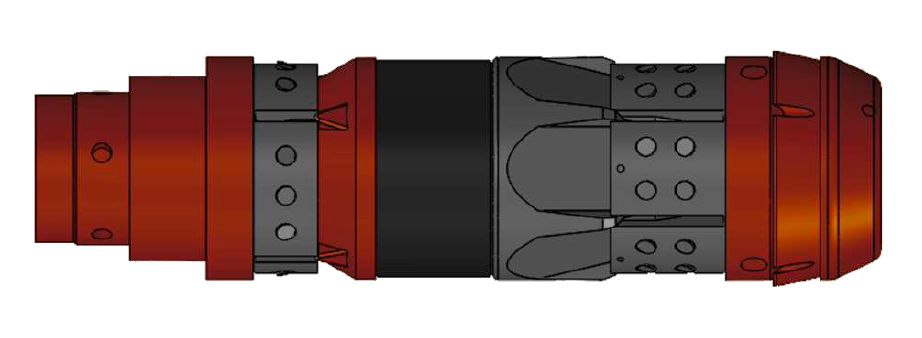

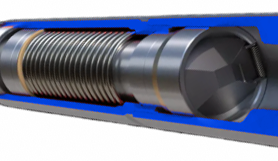

Coiled Tubing Hydraulic Setting Tool

SST Hydraulic Setting Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

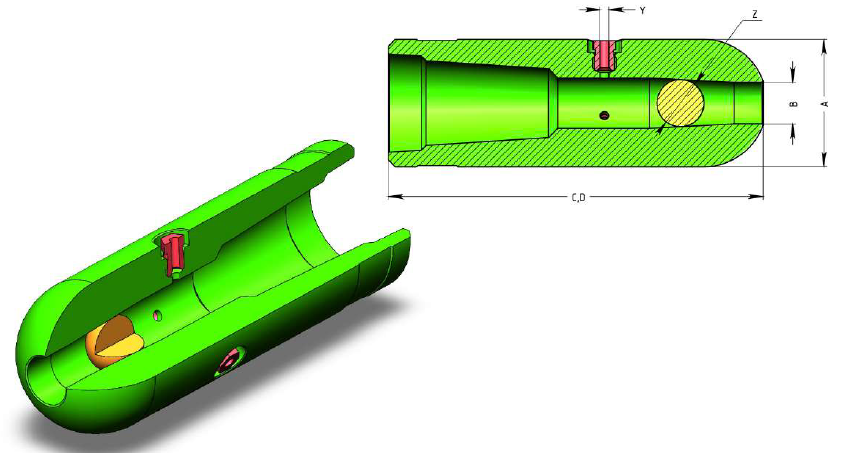

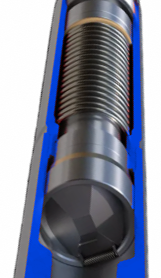

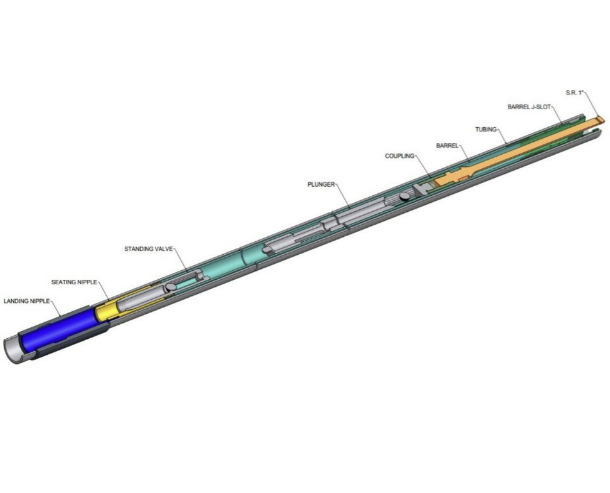

Introducing the SST Hydraulic Setting Tool from Marlin Oil Tools: The Ultimate Mechanical Solution for Downhole Equipment Setting Marlin Oil Tools is proud to present the SST Hydraulic Setting Tool, a fully mechanical downhole tool engineered to revolutionize the setting of bridge plugs and cement retainers within the well casing. Designed for versatility, the SST can be deployed via coil tubing or traditional tubing, making it a crucial component for enhancing well integrity and operational efficiency in oil and gas interventions. Key Features of the SST Hydraulic Setting Tool: Versatile Application: Compatible with both coil tubing and traditional tubing, offering flexible deployment options for various well intervention scenarios. Mechanical Activation: Utilizes a simple yet effective mechanical activation process, where a ball landing in the piston initiates the setting mechanism. Precise Setting Capability: Provides accurate and reliable setting of bridge plugs and cement retainers, crucial for wellbore stability and integrity. High-Pressure Performance: Engineered to withstand the shear pressure required to move the piston and secure the downhole equipment in place. Optimized for Well Interventions: Enhances the efficiency and safety of well interventions by ensuring the precise placement of downhole tools. Ease of Operation: The straightforward mechanical design ensures ease of use, minimizing potential operational complications. Elevate your well intervention and completion processes with the SST Hydraulic Setting Tool from Marlin Oil Tools, a premier mechanical solution designed for the oil and gas industry. This innovative tool simplifies the setting of bridge plugs and cement retainers, ensuring optimal well casing integrity. Compatible with both coil tubing and traditional tubing, the SST offers unparalleled versatility and reliability. With its mechanical activation mechanism and high-pressure performance, the SST Hydraulic Setting Tool is essential for achieving precise downhole equipment placement, enhancing operational efficiency and well integrity. Choose the SST for a streamlined, effective approach to well interventions. Why Choose the SST Hydraulic Setting Tool from Marlin Oil Tools? Flexible Deployment Options: Ensures compatibility with various intervention methods, increasing tool utility. Reliable Mechanical Activation: Simplifies the setting process, reducing the risk of operational errors. Precision in Downhole Settings: Guarantees the accurate placement of bridge plugs and cement retainers for improved well performance. Durability Under Pressure: Built to endure the rigorous conditions of downhole operations, offering lasting performance. The SST Hydraulic Setting Tool by Marlin Oil Tools represents the cutting edge in downhole mechanical solutions, providing operators with a powerful tool for enhancing well completion and intervention outcomes. Incorporate the SST into your operations to ensure efficient, accurate, and reliable downhole equipment setting.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the STM Step Mill from Marlin Oil Tools: Your Go-To Solution for Advanced Well Intervention and Milling Operations Marlin Oil Tools is excited to offer the STM Step Mill, a cutting-edge downhole tool specifically designed to enhance the efficiency of well intervention jobs. Whether you're dealing with bridge plugs, emergency lost equipment, or any obstruction softer than the mill's cutter, the STM Step Mill is engineered to grind and wash out these objects with unmatched efficiency. Key Features of the STM Step Mill: Superior Milling Performance: Designed to navigate and mill through downhole obstructions effectively, ensuring a clear wellbore for optimal production. Reduced Friction Surface: The STM Step Mill features a unique design with less friction surface, enabling it to mill out harder materials more efficiently than traditional tapered mills. Enhanced Weight-on-Bit Application: Its innovative design allows for higher weight on bit without the risk of stalling the downhole motor, maximizing milling effectiveness. Optimal Debris Removal: Equipped with multiple flushing holes, the STM ensures the efficient circulation of drilling fluid to remove milled particles from the well and cool the cutting edge. Durable Carbide Construction: Built with carbide welded onto the body, including options for crushed carbide and various insert designs, the STM Step Mill is designed for longevity and performance in challenging milling conditions. Comprehensive Redress Services: Marlin Oil Tools offers redress services for worn carbide, ensuring your STM Step Mill maintains peak performance throughout its service life. Elevate your well intervention strategies with the STM Step Mill from Marlin Oil Tools, a premier downhole tool designed for the oil and gas industry. Tailored for efficient grinding and removal of downhole obstructions, the STM Step Mill stands out with its reduced friction surface and ability to tackle harder materials without stalling the downhole motor. With its advanced carbide construction, optimal debris removal capabilities, and customizable insert options, the STM Step Mill is the ideal choice for increasing the ID of well restrictions and ensuring smooth wellbore conditions. Opt for Marlin Oil Tools’ STM Step Mill for enhanced well intervention and milling operations, backed by comprehensive redress services to extend tool life and performance. Why Choose the STM Step Mill from Marlin Oil Tools? Advanced Milling Efficiency: Offers unmatched efficiency in grinding down wellbore obstructions. Capability to Mill Harder Materials: Designed to tackle harder materials with greater ease compared to conventional mills. Higher Weight-on-Bit Flexibility: Enhances milling operations by allowing higher weight on bit without compromising tool performance. Customization and Longevity: Provides various carbide insert designs and redress services, ensuring a long service life tailored to your specific operational needs. The STM Step Mill by Marlin Oil Tools represents the forefront of downhole milling technology, offering a powerful solution for oil and gas operators focused on optimizing well intervention outcomes. Incorporate the STM Step Mill into your operations for smoother, more efficient wellbore preparation and obstacle management.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SBA Straight Bar from Marlin Oil Tools: The Essential Downhole Tool for Enhanced Well Intervention Precision Marlin Oil Tools proudly presents the SBA Straight Bar, a specially designed downhole tool that revolutionizes well intervention operations. As an integral part of the Bottom Hole Assembly (BHA), the SBA Straight Bar addresses the critical challenge of coil tubing deformation, ensuring a straighter and more effective pathway for well intervention tools. Key Features of the SBA Straight Bar: Enhanced BHA Stability: The SBA Straight Bar provides the necessary rigidity and straightness to the BHA, minimizing the risk of deformation and ensuring smoother operations. Improved Wellbore Navigation: By maintaining a straighter path, the SBA Straight Bar significantly reduces the chances of the BHA resting against the well walls or encountering obstacles during transitions. Optimal Centering: Its rigid and straight design aids in better centering of the BHA within the wellbore, crucial for the precision of well intervention tasks. Seamless Passage: The SBA Straight Bar facilitates seamless passage through wellbore expansions and recessions, including critical points like blowout preventers, enhancing operational safety and efficiency. Versatile Integration: Designed for easy integration into any BHA configuration, the SBA Straight Bar is suitable for a wide range of well intervention activities, offering unparalleled adaptability. Elevate your well intervention strategies with the SBA Straight Bar from Marlin Oil Tools, a leading-edge solution designed to combat coil tubing deformation and ensure precise downhole operations in the oil and gas industry. The SBA Straight Bar enhances BHA stability, improves wellbore navigation, and ensures optimal centering and seamless passage through wellbore transitions. This tool is an indispensable addition to your BHA, providing the rigidity and straightness necessary for effective well intervention. Choose the SBA Straight Bar for a reliable, efficient, and versatile solution to well intervention challenges. Why Choose the SBA Straight Bar from Marlin Oil Tools? Superior Operational Precision: Ensures straighter coil tubing pathways for enhanced precision in well intervention tasks. Increased Operational Safety: Minimizes the risk of BHA hang-ups and obstructions, ensuring safer operations. Adaptability to Well Conditions: Capable of navigating through complex well architectures, including areas of expansion and recession. Streamlined Well Intervention: Promotes smoother, faster, and more efficient well intervention procedures. The SBA Straight Bar by Marlin Oil Tools represents the forefront of downhole tool technology, providing operators with the means to enhance well intervention accuracy and operational success. Incorporate the SBA Straight Bar into your well intervention toolkit to achieve superior performance and outcomes.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SFF Surface Filter from Marlin Oil Tools: The Ultimate Solution for Protecting Your Downhole Equipment Marlin Oil Tools is proud to offer the SFF Surface Filter, a highly efficient tool designed to safeguard your downhole equipment by filtering mechanical particles from the liquid flow. Engineered with precision, the SFF Surface Filter is an essential addition to any oil and gas operation, ensuring the longevity and reliability of your valuable downhole tools. Key Features of the SFF Surface Filter: Advanced Filtration Technology: Utilizes a wire wound welded to the frame, creating gaps smaller than the permissible size of particles, thereby capturing and retaining mechanical impurities as the liquid flows through. Customizable Filtration Levels: Offers versatile filtration options with membrane fineness primarily available in 0.25 mm, 0.5 mm, and 0.9 mm, allowing operators to select the appropriate level of filtration for their specific well conditions. Durable and Reliable Design: Crafted for durability and long-term use, the SFF Surface Filter stands up to the demanding conditions of oil and gas extraction environments. Protects Sensitive Downhole Tools: Especially beneficial for tools that are highly sensitive to mechanical impurities, such as downhole mud motors with Metal-to-Metal power sections and downhole gas separators. Easy Installation: Designed for straightforward installation in the pipeline running from the pump to the well, ensuring seamless integration into your existing workflow. Enhanced Operational Efficiency: By preventing mechanical particle contamination, the SFF Surface Filter contributes to the smooth operation and reduced maintenance needs of downhole equipment, ultimately saving time and costs. Elevate the protection and efficiency of your oil and gas operations with the SFF Surface Filter from Marlin Oil Tools, a premier downhole tool solution engineered to filter mechanical particles from liquid flows. Featuring advanced filtration technology and customizable filtration levels, the SFF Surface Filter is designed to meet the rigorous demands of the oil and gas industry, ensuring the protection and longevity of sensitive downhole equipment. Whether you're dealing with downhole mud motors, gas separators, or other critical tools, the SFF Surface Filter offers a reliable, durable, and easy-to-install solution to maintain clean liquid flows and enhance operational efficiency. Opt for the SFF Surface Filter and invest in the safety and productivity of your downhole operations. Why Choose the SFF Surface Filter from Marlin Oil Tools? Superior Protection: Provides unmatched filtration to protect downhole equipment from mechanical impurities. Operational Versatility: Adaptable to a wide range of oil and gas operations with customizable filtration to suit diverse needs. Long-lasting Durability: Built to withstand the harsh conditions of oil and gas extraction, ensuring reliability and longevity. Cost-Efficient Maintenance: Reduces the need for frequent downhole tool maintenance, saving both time and operational costs. The SFF Surface Filter by Marlin Oil Tools represents the forefront of filtration technology in the oil and gas industry, providing a vital solution for maintaining the integrity and efficiency of your downhole equipment. Choose the SFF Surface Filter for an enhanced level of protection and operational excellence in your well interventions.

Buy

Made to Order

Manufacturer

New

API

Land Freight

External Slip type Connector for Coiled Tubing

ESC Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the Innovative ESC (External Slip Type Connector) by Marlin Oil Tools: Your Solution for Reliable Coiled Tubing Connections in the Oil and Gas Industry Marlin Oil Tools is at the forefront of delivering cutting-edge solutions tailored for the dynamic needs of the oil and gas sector. Our latest innovation, the ESC (External Slip Type Connector), is designed to revolutionize well intervention operations by providing a secure and efficient method to connect the smooth lower end of coiled tubing (CT) to any downhole tool. Here’s why the ESC stands as a pivotal advancement in coiled tubing technology: Key Features of the ESC (External Slip Type Connector): Innovative Connection Design: The ESC boasts an internal collet mechanism with inward-pointing teeth, ensuring a tight grip on the smooth outer wall of the CT. This design guarantees a secure connection, vital for the successful execution of well intervention jobs. Enhanced Sealing Capabilities: Equipped with two O-rings made from the highly durable FKM 90 material, the ESC offers exceptional sealing, isolating the internal space of the connector from the annulus. This feature is crucial for maintaining the integrity of well operations and preventing fluid leakage. Robust and Reliable: The use of a trapezoidal thread in conjunction with high-quality metals provides a connection that is not only reliable but also capable of withstanding the rigorous demands of downhole activities. The ESC is built to ensure the safety and efficiency of well work. Versatile Tool Connection: The lower housing of the ESC features a standard working taper thread, making it compatible with a wide range of downhole tools. This versatility allows for seamless make-up and enhances the tool's utility across various well intervention scenarios. Marlin Oil Tools presents the ESC (External Slip Type Connector), an essential coiled tubing tool for oil and gas well intervention. Designed to securely link the smooth lower end of CT to threaded downhole tools, the ESC is engineered for reliability and efficiency. Featuring an internal collet with inward-pointing teeth for a firm grip, and dual O-rings made from FKM 90 for superior sealing, this connector ensures operational integrity. With its trapezoidal thread and high-quality metal construction, the ESC stands as a beacon of durability in harsh downhole environments. Its standard working taper thread accommodates various downhole tools, making it a versatile addition to your well intervention arsenal. Why Choose the ESC from Marlin Oil Tools? Security and Efficiency: The ESC’s innovative design ensures a secure connection between coiled tubing and downhole tools, optimizing well intervention operations. Superior Sealing: With its advanced sealing capabilities, the ESC prevents fluid leakage, protecting the well's integrity. Durability: Built with high-quality materials and a robust thread design, the ESC is designed to endure the toughest downhole conditions. Versatility: Its compatibility with a broad range of downhole tools makes it a flexible solution for various well intervention needs. Elevate your well intervention operations with the ESC (External Slip Type Connector) from Marlin Oil Tools. Contact us today to discover how our solutions can enhance your efficiency and operational success in the oil and gas industry.

Buy

Made to Order

Manufacturer

New

API

Land Freight

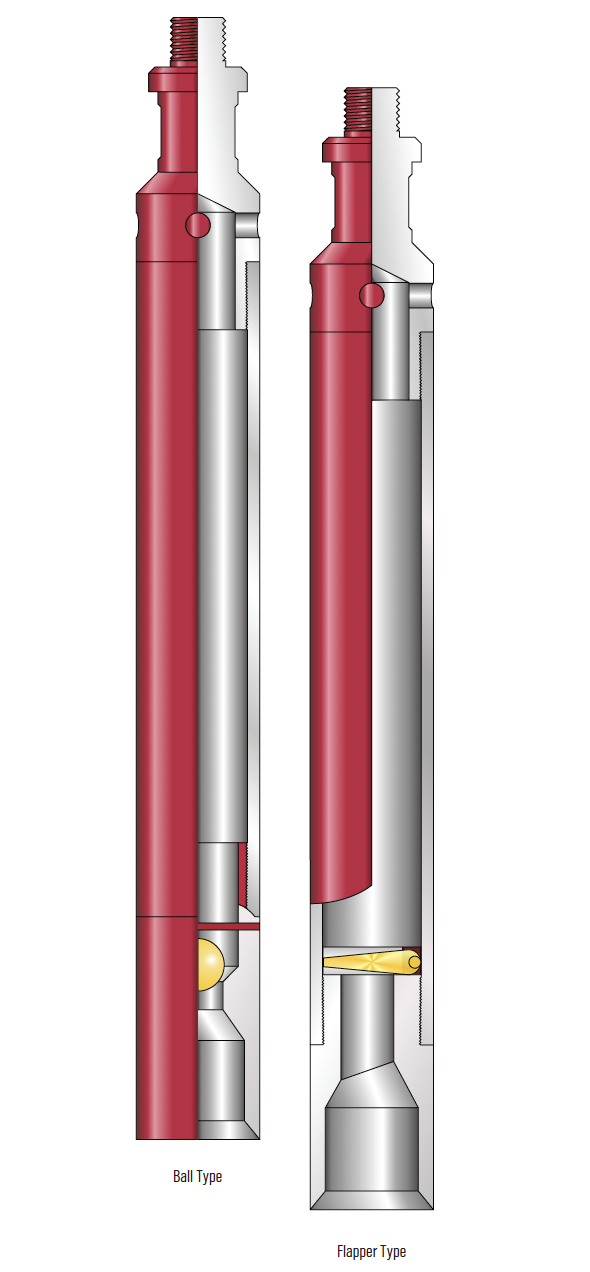

Back Pressure Valve for Coiled Tubing

BPV Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

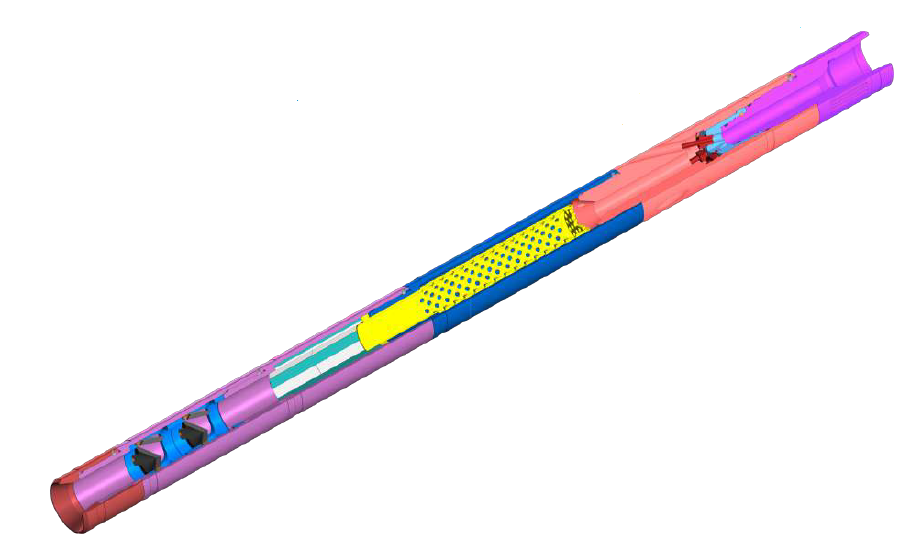

Introducing the BPV (Back Pressure Valve) from Marlin Oil Tools: The Essential Safety Barrier for Coiled Tubing Operations in the Oil and Gas Industry Marlin Oil Tools is proud to present our BPV (Back Pressure Valve), a paramount downhole tool designed to enhance safety and operational integrity during well intervention tasks. Engineered with precision and reliability, the BPV is an indispensable component for maintaining control over well pressure and ensuring the protection of coiled tubing (CT) from potential hazards. Here's a detailed look at the BPV's design, functionality, and benefits, making it a must-have tool for any oil and gas operation. Key Features of the BPV (Back Pressure Valve): Directional Fluid Flow Control: The BPV is designed to allow fluid flow exclusively in one direction—downwards. This capability is crucial for preventing backflow and maintaining operational control during well intervention processes. Dual Flapper Valve System: Equipped with two duplicate cartridges featuring reliable flapper valves, the BPV offers an enhanced level of safety and redundancy. This double flapper back pressure valve system ensures that even if one valve encounters an issue, the other can continue to function effectively, providing an uninterrupted safety barrier. Comprehensive Well Pressure Control: The primary function of the BPV is to act as a safety barrier, preventing well fluids from entering the coiled tubing through the bottom of the Bore Hole Assembly (BHA). This function is vital for the safety of operations and the preservation of equipment integrity. Protection Against Mechanical Particles and Aggressive Environments: In addition to controlling well pressure, the BPV serves an auxiliary role in protecting the coiled tubing from mechanical particles and potentially aggressive well environments, such as those containing H2S and CO2. These elements can cause significant damage to the CT if allowed entry, making the BPV's protective capability critical for long-term equipment durability. Essential Tool for Every Job: Given its crucial safety and protective functions, the BPV is typically run on each well intervention job, underscoring its importance in the toolkit of downhole operations. Elevate your well intervention safety and efficiency with the BPV (Back Pressure Valve) from Marlin Oil Tools, a leading solution in oil and gas coiled tubing tools. Designed for downhole applications, the BPV features a double flapper valve system to ensure fluid flows only downwards, creating an effective barrier against well pressure. This safety essential prevents well fluid backflow into the CT, offering protection from mechanical particles and harsh environments like H2S and CO2. With dual reliable cartridges, the BPV is a critical component for every well intervention job, safeguarding both personnel and equipment by maintaining operational integrity and preventing damage from aggressive well conditions. Why Choose the BPV from Marlin Oil Tools? Unparalleled Safety and Control: Provides a reliable safety barrier for well pressure control, crucial for operational safety. Dual Valve Redundancy: Ensures continued operation and safety even if one valve fails, thanks to its double flapper valve design. Comprehensive Protection: Guards coiled tubing against mechanical damage and corrosion from aggressive well environments. Operational Necessity: An indispensable tool for every well intervention job, highlighting its importance in maintaining a safe and efficient operation. The BPV (Back Pressure Valve) by Marlin Oil Tools represents the pinnacle of safety and efficiency in coiled tubing operations within the oil and gas industry. Incorporate the BPV into your operations to ensure the highest standards of safety and equipment integrity. Contact Marlin Oil Tools today to learn more about how our innovative solutions can support your operational needs.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Coiled Tubing Hydraulic Disconnect

HDI Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the HDI (Hydraulic Disconnect) from Marlin Oil Tools: The Ultimate Safety and Efficiency Tool for Coiled Tubing Operations in Oil and Gas Marlin Oil Tools proudly presents the HDI (Hydraulic Disconnect), a sophisticated downhole tool designed to enhance safety and operational efficiency during workover and other well jobs. As a critical component of the borehole assembly (BHA), the HDI facilitates a controlled split of the BHA, offering a reliable solution for managing challenging downhole conditions. Discover the unparalleled benefits and features of the HDI, making it an indispensable tool for your coiled tubing operations. Key Features of the HDI (Hydraulic Disconnect): Controlled BHA Splitting: The HDI is engineered to perform a precise and controlled split of the BHA, separating the upper part from the lower part on demand. This feature is invaluable for targeted intervention and mitigating risks associated with BHA retrieval. Simple Activation Mechanism: Activation of the HDI is achieved by dropping a steel ball through the coil tubing from the surface. The ball travels down the length of the CT, seating in the piston within the HDI, initiating the disconnect process. Pressure-Activated Release: Upon the ball seating, downward flow ceases, allowing pressure to build above the ball. Once the pressure reaches a specific shear level, shear screws are cut, enabling the top and bottom housings of the HDI to disconnect smoothly. Versatile Utility: The HDI is suitable for any operation where there is a risk of the BHA becoming stuck in the well. It provides a safer and more controlled alternative to overpulling, significantly reducing the risks of equipment loss or damage. Elevate your well intervention strategies with the HDI (Hydraulic Disconnect) from Marlin Oil Tools, a leading-edge solution designed for maximum operational safety and efficiency in the oil and gas sector. The HDI ensures a controlled, precise separation of the BHA, utilizing a simple yet effective steel ball activation mechanism for hassle-free operation. Ideal for workover and other critical well jobs, the HDI's pressure-activated release system offers a reliable disconnect in situations where BHA sticking poses a risk. Choose the HDI for a safer, more efficient approach to managing downhole challenges, minimizing downtime, and enhancing overall operational success. Why Choose the HDI from Marlin Oil Tools? Enhanced Operational Safety: Minimizes risks associated with stuck BHA, providing a controlled disengagement method. Streamlined Activation: The steel ball activation mechanism simplifies the disconnect process, enhancing ease of use. Operational Flexibility: Adaptable to a wide range of well jobs, the HDI is essential for operations prone to BHA sticking. Risk Mitigation: Offers a safer alternative to overpulling, reducing the likelihood of equipment damage and operational delays. The HDI (Hydraulic Disconnect) by Marlin Oil Tools represents the forefront of innovation in downhole safety and efficiency, ensuring your coiled tubing operations are supported by the highest standards of reliability and control. Incorporate the HDI into your coiled tubing operations to achieve optimal outcomes in well intervention and maintenance tasks.

Buy

Made to Order

Manufacturer

New

API

Land Freight

External Dimple Connector for Coiled Tubing

EDC Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

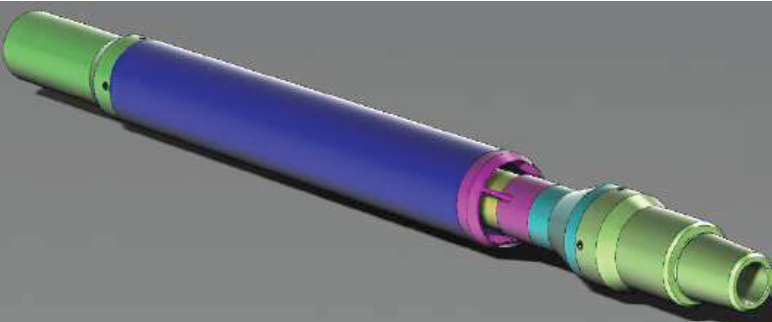

Introducing the Revolutionary EDC (External Dimple Connector) from Marlin Oil Tools: The Essential Link for Coiled Tubing Applications in the Oil and Gas Industry Marlin Oil Tools proudly presents our state-of-the-art EDC (External Dimple Connector), a groundbreaking solution designed to seamlessly integrate the smooth lower end of coiled tubing (CT) with any requisite downhole tool for efficient well intervention operations. The EDC stands out in the oil and gas sector for its innovative design and unparalleled reliability, making it a must-have for your well intervention toolkit. Key Features of the EDC (External Dimple Connector): Seamless Integration: The EDC provides a flawless connection between the smooth-walled end of the CT and the threaded interface of downhole tools, ensuring a secure and efficient link for well intervention jobs. Advanced Connection Mechanism: Equipped with a unique holes matrix in the upper housing, the EDC utilizes set screws installed in precision-pressed dimples, offering a robust and reliable connection without compromising the integrity of the coiled tubing. Threaded Lower Part: The connector's lower portion features a meticulously designed thread for attaching any downhole tool, facilitating a versatile and adaptable solution for various well intervention needs. High-Performance Sealing: Installation of the EDC is enhanced with two O-rings made from the durable FKM 90 material, providing a high-integrity seal between the internal space of the connector and the annulus, ensuring operational safety and efficiency. Effortless Installation: The EDC can be effortlessly installed using a dimple tool, capable of mechanical or hydraulic pressing, simplifying the assembly process and minimizing downtime during critical operations. At Marlin Oil Tools, we understand the complexities and challenges of well intervention in the oil and gas industry. Our EDC (External Dimple Connector) is designed to address these challenges, offering a reliable, efficient, and high-quality connection solution for coiled tubing operations. Whether you are conducting routine maintenance, stimulation, or any other well intervention job, the EDC ensures a seamless, secure, and effective operation. Why Choose Marlin Oil Tools' EDC? Unmatched Reliability: Engineered for durability and performance, the EDC withstands the harsh conditions of downhole operations, ensuring reliability when it matters most. Versatility: Compatible with a wide range of downhole tools, the EDC offers unparalleled flexibility for your well intervention needs. Quality Assurance: At Marlin Oil Tools, quality is at the forefront of everything we do. The EDC is manufactured to the highest industry standards, ensuring peak performance and safety. Elevate your coiled tubing operations with the EDC (External Dimple Connector) from Marlin Oil Tools. Contact us today to learn more about how our innovative solutions can enhance your well intervention strategies and drive operational success.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the CBP Composite Bridge Plug from Marlin Oil Tools: The Cutting-Edge Solution for Temporary Well Barrier Operations Marlin Oil Tools is proud to present the CBP Composite Bridge Plug, a state-of-the-art downhole tool designed for optimal performance in oil and gas well operations. Engineered for easy installation using a hydraulic Setting Tool (STT), the CBP Composite Bridge Plug provides an effective temporary barrier within the well, isolating underlying intervals for enhanced operational control and safety. Key Features of the CBP Composite Bridge Plug: Efficient Installation: Utilizes a hydraulic Setting Tool (STT) for quick and secure deployment in oil and gas wells. Reliable Well Isolation: Designed to create a temporary barrier, effectively cutting off underlying intervals to manage wellbore integrity. Easy Removal Process: The composite bridge plug can be easily milled away using standard milling BHA, facilitating straightforward removal. Durable and Reliable Construction: Features collets with an easily drilled design, made from high-quality composite materials and reinforced with ceramic cylinders for increased durability. Proven Field Performance: The reliability and effectiveness of the CBP Composite Bridge Plug have been validated through extensive field work, ensuring dependable well isolation. Maximize your well intervention and maintenance operations with the CBP Composite Bridge Plug from Marlin Oil Tools, a premier solution for establishing temporary barriers in oil and gas wells. Engineered with advanced composite materials and ceramic cylinders, the CBP offers unmatched reliability and ease of installation using a hydraulic Setting Tool (STT). Whether you need to isolate wellbore intervals or ensure operational safety, the CBP Composite Bridge Plug's field-proven technology and easy milling process make it an indispensable tool for modern well operations. Choose the CBP for efficient, reliable, and easy-to-remove wellbore isolation. Why Choose the CBP Composite Bridge Plug from Marlin Oil Tools? Superior Wellbore Isolation: Offers effective temporary isolation, improving operational safety and control. Streamlined Installation and Removal: Designed for ease of installation and removal, reducing downtime and operational costs. Advanced Material Construction: Utilizes composite materials and ceramic cylinders for enhanced durability and reliability. Field-Tested Technology: Backed by extensive field testing, ensuring proven performance in various well conditions. The CBP Composite Bridge Plug by Marlin Oil Tools represents the forefront of downhole tool innovation, providing oil and gas operators with a reliable, efficient solution for temporary wellbore isolation. Incorporate the CBP into your operations to benefit from its superior performance and ease of use.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the TPM Tapered Mill from Marlin Oil Tools: The Essential Downhole Tool for Precision Well Intervention Marlin Oil Tools is proud to offer the TPM Tapered Mill, a specialized downhole tool crafted for superior performance in well intervention tasks. Designed to navigate and resolve wellbore challenges efficiently, the TPM Tapered Mill excels in grinding and washing out objects that are softer than the mill's cutters, from intentionally placed equipment like bridge plugs to unexpectedly lost tools. Key Features of the TPM Tapered Mill: Versatile Milling Capabilities: Engineered to remove a wide array of downhole obstructions, ensuring a clear path for well operations. Optimized Debris Removal: Equipped with multiple flushing holes, the TPM facilitates the circulation of drilling fluid, efficiently clearing milled particles from the well and cooling the cutting edge. Durable Carbide Construction: Features a robust body with carbide welded on, available in crushed carbide and various insert designs to match milling requirements against different materials. Customizable Geometry: The tapered design is tailored to enhance the ID of wellbore restrictions, with customizable geometry including the length of the cone, minimal OD, and maximal OD based on client specifications. Extended Service Life: The longevity of the carbide components is maximized through optimal milling modes and can be further extended with Marlin Oil Tools' comprehensive redress services for worn carbide. Powered by Downhole Motors: Rotation facilitated by a downhole motor enhances the milling efficiency, making the TPM an integral part of the well intervention toolkit. Elevate your well intervention operations with the TPM Tapered Mill from Marlin Oil Tools, a leading-edge solution designed for the efficient removal of downhole obstructions in the oil and gas industry. This downhole tool combines advanced milling technology with a tapered design to effectively increase the ID of wellbore restrictions, ensuring operational success. With its durable construction, customizable geometry, and optimized debris removal capabilities, the TPM Tapered Mill is essential for achieving a clear and operational wellbore. Whether addressing emergency lost equipment or routine well maintenance, the TPM Tapered Mill offers precision, efficiency, and reliability. Trust Marlin Oil Tools for your well intervention needs and experience unparalleled performance and service life with the TPM Tapered Mill. Why Choose the TPM Tapered Mill from Marlin Oil Tools? Precision Milling: Delivers unmatched efficiency in grinding down and removing wellbore obstructions. Customization to Fit Operational Needs: Offers tailored solutions to meet specific well intervention challenges. Robust and Reliable: Built to withstand the harsh downhole environment and ensure prolonged tool effectiveness. Expert Support and Services: Backed by Marlin Oil Tools' commitment to quality and customer support, including redress services for extended tool life. The TPM Tapered Mill by Marlin Oil Tools represents the pinnacle of downhole milling innovation, providing a versatile, durable, and efficient solution for well intervention and maintenance operations. Incorporate the TPM Tapered Mill into your toolkit for smoother, more effective well interventions.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Venturi Junk Basket for Coiled Tubing Applications

VJB Venturi Junk Basket![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the VJB Venturi Junk Basket from Marlin Oil Tools: The Advanced Solution for Efficient Well Cleanout Operations Marlin Oil Tools is proud to unveil the VJB Venturi Junk Basket, a cutting-edge downhole tool engineered to tackle the challenge of removing solid debris from wells, especially when particles are too heavy for standard circulation removal. This innovative tool is designed to enhance well intervention procedures, ensuring a clean and unobstructed wellbore essential for optimal production and operational safety. Key Features of the VJB Venturi Junk Basket: Venturi Effect Cleaning: Utilizes the Venturi effect, generated by flow through the tool's nozzles, to efficiently suck solid debris and well fluid into the basket for removal. Selective Debris Filtration: Features a filter that captures large particles (>3 mm in diameter) while allowing liquid to return to the annulus, ensuring effective debris removal without losing valuable well fluids. Secure Debris Retention: Equipped with cartridges and flapper valves inside the basket to securely hold debris, even when circulation is halted, preventing backflow. Magnetic Debris Capture: Offers the option to install a magnet within the tool, enhancing the capture of small metal particles and ensuring a thorough cleanout. Expandable Collection Volume: Can be fitted with an extended housing to increase the internal volume for debris collection, accommodating larger cleanout operations. Integrated Milling Capability: When faced with compressed debris, the VJB can be mounted on a downhole motor with a crown mill shoe, allowing for the milling of compressed debris while simultaneously sucking up drilled particles. Elevate your well cleanout operations with the VJB Venturi Junk Basket from Marlin Oil Tools, a premier downhole tool designed for the efficient removal of solid debris in oil and gas wells. By harnessing the Venturi effect, the VJB enhances debris removal capabilities, particularly for heavy particles that are difficult to extract via standard circulation. With its innovative features, including selective filtration, secure debris retention, and optional magnetic capture, the VJB Venturi Junk Basket is an essential tool for maintaining well integrity and optimizing production. Whether dealing with loose or compressed debris, the VJB offers customizable solutions, including expandable collection volumes and integrated milling functionality, making it a versatile choice for comprehensive well cleanout needs. Why Choose the VJB Venturi Junk Basket from Marlin Oil Tools? Enhanced Cleanout Efficiency: Leverages the Venturi effect for superior debris removal performance. Versatile Debris Management: Captures a wide range of particle sizes, from large solids to small metal fragments. Customizable Tool Options: Adaptable design with optional extensions and magnetic capabilities to suit specific operational needs. Operational Versatility: Suitable for both loose and compressed debris, ensuring thorough well cleanout under various conditions. The VJB Venturi Junk Basket by Marlin Oil Tools represents the forefront of well cleanout technology, offering unparalleled efficiency and adaptability in debris removal operations. Incorporate the VJB into your well maintenance and intervention strategies for cleaner, safer, and more productive wells.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the CEM Cement Mill from Marlin Oil Tools: The Premier Solution for Efficient Wellbore Milling Operations Marlin Oil Tools proudly presents the CEM Cement Mill, a state-of-the-art milling tool designed to optimize cement mill-out operations and tackle various downhole obstacles in oil and gas wells. Engineered for versatility and efficiency, the CEM Cement Mill is capable of grinding and washing out any object within the well that is softer than the mill's cutters, ranging from intentionally placed equipment like bridge plugs to inadvertently lost tools. Key Features of the CEM Cement Mill: Optimized for Cement Removal: Specifically designed to excel in cement mill-out operations, ensuring a clean and clear wellbore for subsequent interventions. Broad Milling Applications: Capable of milling a wide array of downhole obstacles, providing flexibility across well intervention tasks. Effective Debris Management: Equipped with multiple flushing holes, the CEM Cement Mill facilitates the circulation of drilling fluid, which efficiently removes milled particles and cools the cutting edge. Superior Cutting Technology: Features durable carbide inserts welded inside the mill body, offering exceptional grinding performance and longevity. Cooling and Lubrication: The circulation of drilling fluid not only removes debris but also prevents overheating, extending the life of the carbide inserts. Redress Services: Marlin Oil Tools offers comprehensive redress services for worn carbide inserts, ensuring your CEM Cement Mill remains at peak performance. Elevate your well intervention and milling operations with the CEM Cement Mill from Marlin Oil Tools, a leading-edge solution designed for unparalleled efficiency in cement mill-out and obstacle removal in the oil and gas industry. With its advanced design, the CEM Cement Mill tackles downhole challenges with ease, ensuring operational success. Whether you're dealing with cement, bridge plugs, or lost equipment, the CEM Cement Mill's carbide inserts and flushing holes ensure effective milling and debris removal, enhancing wellbore integrity and facilitating subsequent operations. Opt for Marlin Oil Tools' CEM Cement Mill for your milling needs and experience the difference in precision, efficiency, and durability. Why Choose the CEM Cement Mill from Marlin Oil Tools? Versatile Milling Solution: Offers a versatile tool for a wide range of downhole milling challenges. Enhanced Operational Efficiency: Designed to maximize milling efficiency and minimize downtime. Durable and Reliable: Built with high-quality materials and carbide inserts for prolonged service life. Comprehensive Support: Backed by Marlin Oil Tools' expert redress services, ensuring your tool is always in optimal condition. The CEM Cement Mill by Marlin Oil Tools represents the forefront of downhole milling technology, providing oil and gas operators with a reliable, efficient, and versatile tool for enhancing well intervention outcomes. Incorporate the CEM Cement Mill into your operations for smoother, more effective wellbore preparation and obstacle management.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the BBT Boot Basket from Marlin Oil Tools: The Ultimate Solution for Efficient Debris Management in Oil and Gas Operations Marlin Oil Tools is proud to present the BBT Boot Basket, a cutting-edge tool designed for optimal debris management during oil and gas drilling, milling, or garbage collection operations. Engineered to trap large pieces of sludge that cannot be circulated out of the well to the surface, the BBT Boot Basket is an essential component for maintaining clean and efficient wellbore conditions. Here’s why the BBT Boot Basket is a must-have for your operations. Key Features of the BBT Boot Basket: Efficient Debris Capture: Utilizing a unique design, the BBT Boot Basket efficiently captures large particles. The high-speed upstream flow created by the annular space's small restriction in the lower part of the tool allows for effective trapping as the flow slows down when it passes the upper part, where the gap increases sharply. Optimal Positioning: Designed to be positioned as close to the mill or bit as possible, the BBT Boot Basket ensures that milling procedures can be carried out in normal mode with standard circulation, maximizing debris capture efficiency. Enhanced Capacity Options: To accommodate varying operational needs, several BBT Boot Baskets can be used within the same Bottom Hole Assembly (BHA) to increase overall debris trapping capacity. Customizable Length: Recognizing the diverse requirements of our clients, Marlin Oil Tools offers the option to produce the BBT Boot Basket in different lengths, ensuring a perfect fit for every operation. Durability and Ease of Maintenance: The simple yet robust design of the BBT Boot Basket not only ensures excellent strength characteristics for withstanding torsion and tension but also allows for quick and easy redress, minimizing downtime and extending tool life. Elevate your wellbore cleaning operations with the BBT Boot Basket from Marlin Oil Tools, a premier solution for trapping large sludge particles during drilling, milling, or garbage collection in the oil and gas industry. Featuring an efficient design for optimal debris capture and customizable length options, the BBT Boot Basket enhances operational cleanliness and efficiency. With the capability to position the tool close to the mill or bit and the option to use multiple units for increased capacity, the BBT Boot Basket is adaptable to various operational needs. Its durable construction and easy maintenance ensure long-term reliability and performance. Choose the BBT Boot Basket for a cleaner, more efficient wellbore. Why Choose the BBT Boot Basket from Marlin Oil Tools? Superior Debris Management: Effectively traps large particles, ensuring cleaner wellbore conditions. Customizable and Versatile: Offers options for different lengths and the use of multiple baskets for increased capacity. Durable and Easy to Maintain: Designed for durability and easy redress, reducing operational downtime and costs. Optimized for Efficiency: Enhances milling procedures and maintains normal circulation, optimizing well intervention operations. For operators looking to improve their debris management strategy and maintain efficient well operations, the BBT Boot Basket by Marlin Oil Tools is the ideal solution. Contact us today to learn more about how our innovative oil and gas coiled tubing tools can benefit your operations.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools: The Premier Solution for Well Cleaning and Debris Removal in the Oil and Gas Industry Marlin Oil Tools is proud to unveil the MGN Flat Bottom Downhole Magnet, a specialized downhole tool engineered to address the critical need for thorough well cleaning in oil and gas operations. Designed to efficiently remove small metal debris, such as chips and scale, the MGN Flat Bottom Downhole Magnet is essential for maintaining the integrity and operational efficiency of wells. With its unique flat bottom design and internal passage for simultaneous flushing, this tool is a game-changer for well work preparation. Key Features of the MGN Flat Bottom Downhole Magnet: Optimized Debris Removal: The flat bottom design enhances the magnet's ability to capture and remove metal debris from the well, ensuring a cleaner wellbore environment. Simultaneous Well Flushing: Features an internal passage hole, allowing for well flushing during magnet operation, thereby maximizing cleaning efficiency and reducing downtime. Versatile Design: Capable of accommodating various well conditions with a magnetic surface that can be located along the tool body or from the end, offering flexibility in application. Customizable Connections: Marlin Oil Tools provides customizable connecting threads to ensure seamless integration with your existing downhole tool configurations. Prevention of Complications: By removing foreign metal objects and debris, the MGN Flat Bottom Downhole Magnet minimizes the potential for operational complications and accidents. Essential for Well Maintenance: Acts as a crucial step in well work preparation, helping to clear the way for further well intervention and maintenance activities. Elevate your well intervention and maintenance strategies with the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools, a leading-edge solution for effective well cleaning in the oil and gas sector. This downhole magnet is specifically designed to remove metal debris, ensuring well integrity and operational efficiency. With its unique flat bottom design and internal flushing capability, the MGN Flat Bottom Downhole Magnet stands out as an essential tool for any well work preparation, offering customizable connections for a perfect fit with your operations. Choose Marlin Oil Tools for reliable, efficient, and versatile well cleaning solutions. Why Choose the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools? Superior Cleaning Efficiency: Designed to effectively capture and remove a wide range of metal debris from wells. Operational Versatility: Adapts to various well conditions and integrates seamlessly with your BHA for comprehensive cleaning. Enhanced Safety Measures: By clearing metal debris, it significantly reduces the risk of downhole complications and accidents. Customization Options: Offers tailor-made connecting threads to fit your specific operational requirements and tool setups. The MGN Flat Bottom Downhole Magnet by Marlin Oil Tools represents the forefront of downhole cleaning technology, providing operators with a robust tool for enhancing well performance and safety. Incorporate the MGN Flat Bottom Downhole Magnet into your well maintenance protocols to achieve cleaner, safer, and more efficient well operations.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Introducing the FRO (Flow Release Overshot) from Marlin Oil Tools: Your Ultimate Solution for Efficient Fishing Operations in Oil and Gas Well Interventions Marlin Oil Tools is proud to present the FRO (Flow Release Overshot), a sophisticated downhole tool specifically designed to revolutionize fishing operations during well intervention. The FRO is engineered to offer unparalleled efficiency and reliability in capturing and retrieving objects ("fish") from the wellbore, ensuring smooth and successful operations. With its replaceable collet and adaptable design, the FRO is a must-have tool for any well intervention toolkit. Key Features of the FRO (Flow Release Overshot): Versatile Collet Design: The FRO features a replaceable collet system designed to catch and secure a smooth surface of fish, accommodating a wide range of outer diameters from 1.0” to 2-1/8”. Customizable Bottom Guide: Upon client request, the bottom of the overshot can be equipped with a guide leap, enhancing its ability to guide and catch fish with precision. Secure Fish Retrieval: The collet of the FRO overshot securely grips the fish, holding it firmly during the lifting process out of the well, ensuring safe and efficient retrieval. Pressure-Release Mechanism: In situations where the captured object cannot be released from the well, the FRO allows for an easy disengagement by applying pressure through the coil tubing, offering an additional layer of operational safety. SEO Optimized Description for Marlin Oil Tools’ FRO: Elevate your well intervention and fishing operations with the FRO (Flow Release Overshot) from Marlin Oil Tools, a leading downhole tool engineered for maximum retrieval efficiency in the oil and gas industry. Featuring a replaceable collet for capturing a range of fish sizes and an optional guide leap for enhanced precision, the FRO ensures secure and successful fish recovery. With its unique pressure-release mechanism, the FRO offers an innovative solution for challenging fishing scenarios, making it an essential component of your well intervention arsenal. Choose the FRO for reliable, efficient, and safe fishing operations. Why Choose the FRO from Marlin Oil Tools? Adaptable to Various Fish Sizes: Designed to accommodate a broad range of fish diameters, ensuring versatility across operations. Enhanced Precision and Safety: Optional guide leap improves catch accuracy, while the secure grip minimizes risks during retrieval. Innovative Release Mechanism: Provides a reliable method for disengaging from stubborn fish, enhancing operational flexibility. Durability and Reliability: Constructed to withstand the harsh conditions of downhole environments, ensuring consistent performance. The FRO (Flow Release Overshot) by Marlin Oil Tools represents the forefront of innovation in well intervention fishing operations. Incorporate the FRO into your operations to achieve optimal outcomes in fish retrieval, backed by the reliability and efficiency Marlin Oil Tools is known for.

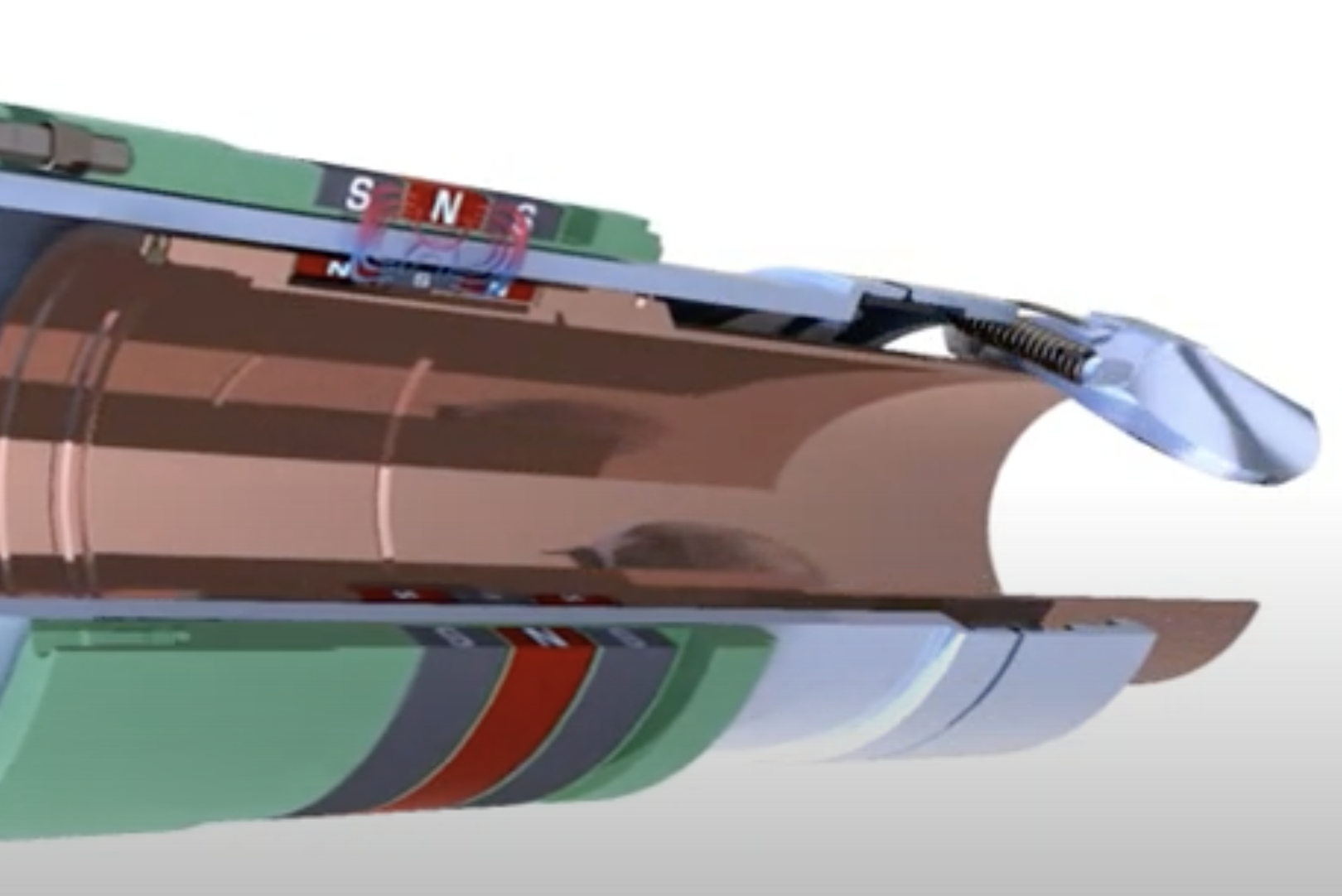

Tubing Retrievable Surface Controlled Subsurface Safety Valve 2-7/8 inch SP

SCSSSV - SP![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The SP™ tubing-retrievable safety valve (TRSV) is a single rod-piston non-elastomer flapper valve designed for hostile environments and extended life applications where ultimate reliability is required. Potential leak paths within the valve are minimized with the single rod-piston design. The piston achieves a metal-to-metal (MTM) seal at its uppermost and lowermost positions to seal well pressure from the control system. The SP valves incorporate flappers using spherical radius sealing surfaces that help greatly improve seal reliability. The spherical radius design provides full MTM sealing integrity. For applications where either the OD or ID is restrained, SP valves incorporate a contoured flapper. OD/ID relationships are improved by the contoured flapper design, which helps provide superior MTM sealing when compared to other forms of curved flapper technology. Applications » For applications requiring ultimate reliability and longevity, such as high-temperature/high-pressure, and subsea completions, or hostile well environments Features » Non-elastomer dynamic piston seals » MTM static seal at upper and lower piston positions » MTM body joints » Flow tube fluted guide » 100% MTM flapper » Concentric thrust bearing » Wiper ring on upper flow tube » Cleanout ports in flow tube’s upper end » Internal exercise profile » Flow tube shock absorber » MTM face seat at flow tube downstop » Setting depths to 9,000 ft (2743 m) » Critical components isolated from well debris with valve in open position » Area above flow tube free of solids buildup » Flow tube can be manipulated by slickline » Protected from high flow rate slam closures *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

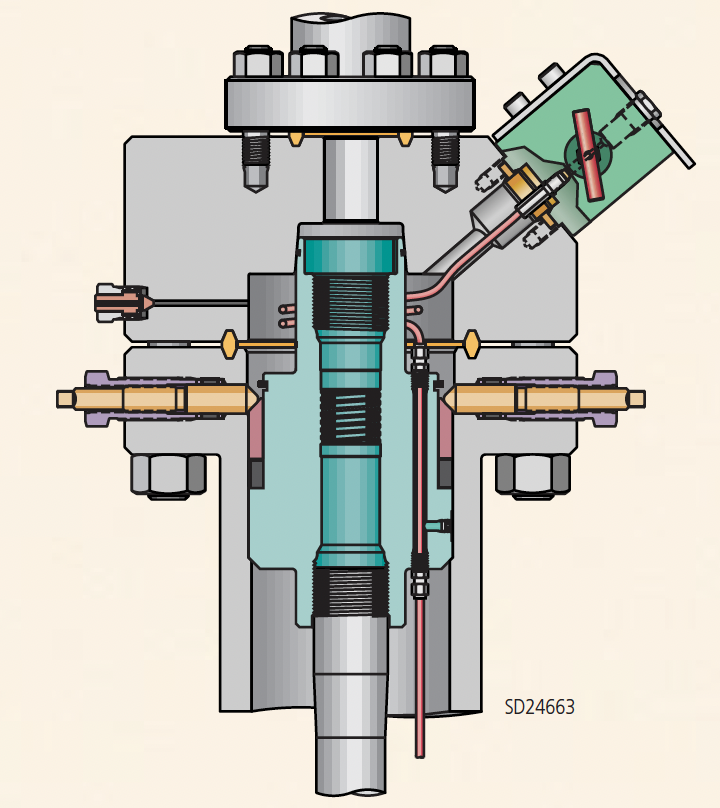

The DepthStar® tubing-retrievable safety valve (TRSV) is a revolutionary concept in the realm of surface controlled subsurface safety valves. Unlike other TRSVs, the DepthStar valve functions completely independent of well pressure; therefore, it is able to operate at consistently low hydraulic pressures, making it an ideal solution for deepwater completions. Previously, solutions to wellbore isolation of the piston required additional seals and/or gas-charged chambers where their reliability is heavily dependent on elastomeric seals and the permanent, long-term containment of a dome charge. The DepthStar valve, through the use of a revolutionary magnetic coupler, allows for positioning the hydraulic actuator completely out of the tubing wellbore. By repositioning the hydraulic actuator outside the tubing wellbore, the DepthStar valve becomes the world’s first 100% metal-to-metal (MTM) safety valve that contains no moving seals within the tubing wellbore. This reduction in seals combined with an intrinsically simple design makes the DepthStar TRSV inherently reliable. The DepthStar TRSV operates with a low operating pressure, making it an ideal solution for deep-set applications. Features » No moving seals exposed to the tubing wellbore » 100% MTM sealing within the tubing wellbore » Less than 5,000-psi maximum valve opening capability regardless of setting depth or pressure » Minimized number of body connections » Proven MTM, non-elastomer hydraulic actuator » Isolated flow tube *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

5-1/2 inch Wireline Retrievable FXE SCSSV

WR-SCSSSV FXE![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The FXE wireline-retrievable flapper valve, which is normally closed, is held open by hydraulic control pressure from the surface. The valve operates on a hydraulic piston principle. To open, hydraulic pressure slightly higher than the well pressure is applied to move the piston downward. This pressure unseats the secondary seat, allowing pressure to enter through equalizing ports. Then, as additional hydraulic pressure is applied to the piston, it continues downward movement, pushing the flapper open. The flapper hinge assembly is designed such that the force on the piston is not applied directly on the hinge pin. Upon loss of hydraulic pressure in the control line, the valve’s large spring serves to lift the hydrostatic head of the control fluid. The flapper spring is designed to close the valve when the piston moves up past the flapper. Opening Prong Nose Seal The FXE valve uses the valve housing as the downstop for the opening prong. This metal-to-metal (MTM) interface is designed to prevent flow from passing between the valve housing and the opening prong. The MTM interface isolates the flapper and seat from fluid flow while the valve is open. This design creates an MTM interface with the full force exerted by the hydraulic piston, minus the spring compression force, holding the two metal faces in contact. Radius of Curvature at Flow Entrance Halliburton conducted a study with various curvatures on the entrance to the valve. The study tested abrasive fluids flowing through different test subs and examined the resulting wear patterns. As a result, an optimum radius of curvature was determined and implemented on the valve housings of all wireline-retrievable safety valves. Applications » General production completions Features » Equalizing-type flapper closure » Solid construction flapper made from bar stock » Spherical radius seat on flapper improves seal reliability » Sealing and seating surfaces are out of the well production flow path when valve is in the open position *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

![]() ALCiT in Mississauga

ALCiT in Mississauga

Unlock the Future of Datacenter Virtualization with ALCiT's VMware Partnership In the realm of technological innovation, few names shine as brilliantly as VMware. As part of the Dell EMC family and the driving force behind transformative tech advancements, VMware stands as a beacon of excellence in the IT landscape. ALCiT is thrilled to be more than just a partner – we're your gateway to a future defined by datacenter virtualization. VMware: The Powerhouse Behind Industries With an ecosystem of over 30,000 partners, VMware's influence has been nothing short of revolutionary. Through tech innovations that have changed the very fabric of industries, VMware has redefined what's possible in the digital realm. ALCiT's partnership with VMware is your ticket to harnessing this unparalleled potential. Virtualization: The Heartbeat of Efficiency Efficiency Redefined: No datacenter achieves its true potential without the magic of virtualization. At its core, VMware's platform embodies efficiency, enabling you to manage your resources with unmatched ease. Mastery of the Platform: At ALCiT, VMware isn't just a tool; it's our canvas. We know VMware like the back of our hand – from selling and configuring to maintaining and maximizing its capabilities. Seamless Integration: Virtualization isn't just about technology; it's about integration. ALCiT ensures that VMware seamlessly integrates into your ecosystem, propelling you toward unparalleled efficiency. Unleash the Power of VMware with ALCiT Consultation: Dive deep into the world of VMware with ALCiT's expert guidance. Together, we'll map out a virtualization strategy that empowers your digital journey. Configuration and Implementation: From conceptualization to reality, ALCiT configures and deploys VMware to align perfectly with your needs. Ongoing Support: Virtualization isn't just a one-time event; it's an ongoing journey. ALCiT's unwavering support ensures that your VMware experience remains flawless. Embrace the Future Today ALCiT's partnership with VMware isn't just a collaboration; it's your path to datacenter transformation.

Service

Made to Order

Service

New

ISO

Gas Tight Casing Patch GTX-SPAN

GTX-SPAN![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

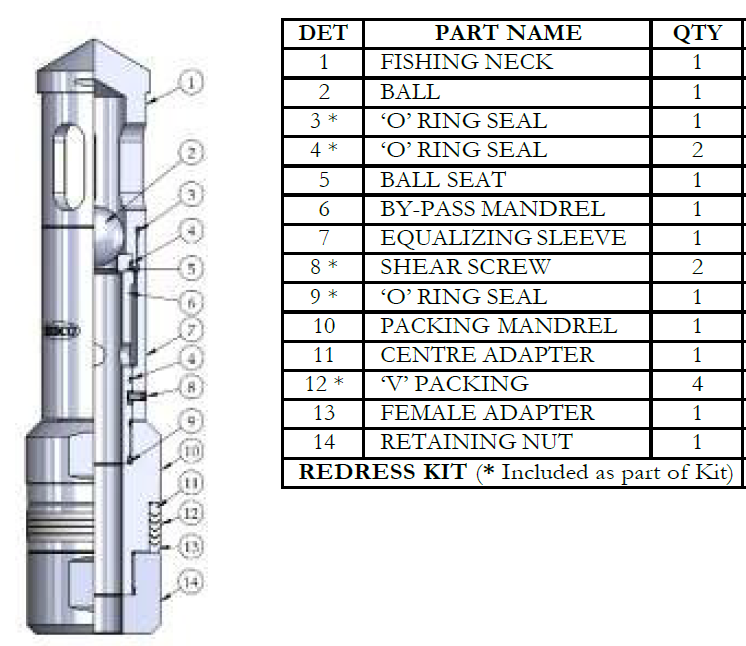

Looking for a heavy-duty, permanent solution for sealing splits, holes or perforations in your tubing and casing? Look no further than the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS! Our GTX-SPAN System is the first effective gas tight patch on the market, thanks to the premium sealing elements in each component. Each element contains two elastomer seals, providing superior gas shut off capabilities. The GTX-SPAN System is incredibly versatile, and can be run on electric wireline, tubing, or coil tubing, and set with a pressure setting tool (electrical, mechanical, or hydraulic). The large bores ensure easy passage of tools and equipment, minimizing restriction to fluid flow. Customizable for most well applications, including premium alloys, restrictions, and geothermal well applications, our GTX-SPAN System Tubing/Casing Patch is the solution you need for your sealing needs. Our system consists of three basic components: a top metal element with an expandable elastomer seal, a tubular extension, and a bottom metal element with an expandable elastomer seal. Various patch lengths can be obtained by adding tubular extensions, making it a modular and versatile solution for any well. During the setting process, the pressure setting tool exerts a pushing force on the top tapered metal swage and a pulling force on the bottom tapered metal swage. Both swages are driven into the metal sealing elements (with expandable elastomer seals), which expand outward into the casing wall, providing both a metal-to-metal and an elastomer seal. At a predetermined force, a calibrated weak point shears, and the setting process ceases. A collapsible setting collet located in the bottom swage retracts and allows the setting equipment to be retrieved. The interval is now fully isolated with metal and expandable elastomer seals. ID OILTOOLS highly recommends the use of a casing scraper before patch installation to rid the interval of foreign matter and the use of a casing caliper to provide an accurate record of casing I.D. and conditions. A gauge ring or drift run is a minimum requirement. Choose the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS for the first effective gas tight patch on the market. Contact us today to learn more!

Buy

In Stock

Product & Service

New

API

Sea Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Maximize Your Downhole Success with HOCA Oil Tools' Running Tools for Lock Mandrels In the complex world of downhole operations, the necessity for precision, safety, and efficiency cannot be overstated. HOCA Oil Tools, a leader in providing advanced downhole slick line tools, introduces a range of Running Tools specifically designed for Lock Mandrels, ensuring seamless integration and operation in your wellbore activities. HOCA’s Running Tools for Lock Mandrels: Precision, Versatility, and Reliability Our Running Tools for Lock Mandrels are engineered with precision, crafted to deliver unmatched performance in downhole settings. These tools are essential for setting or positioning downhole flow controls and devices at predetermined depths efficiently and accurately. Designed for versatility, they accommodate various sizes and types of Lock Mandrels, ensuring compatibility and flexibility for different downhole requirements. Experience the HOCA Oil Tools Difference At HOCA Oil Tools, we are committed to providing the oil and gas industry with downhole solutions that set new standards in quality, efficiency, and reliability. Our Running Tools for Lock Mandrels are a testament to this commitment, designed to enhance your downhole operations and drive success. Incorporating our Running Tools into your downhole toolkit not only ensures optimal performance but also aligns your operations with the highest standards of precision and safety. With HOCA Oil Tools, you gain a partner dedicated to supporting your downhole success with innovative solutions and exceptional service. Choose HOCA Oil Tools’ Running Tools for your Lock Mandrels and elevate your downhole operations to new heights. Partner with us and experience the difference that precision engineering, reliability, and dedicated support can make in your wellbore activities. Embrace the future of downhole operations with HOCA Oil Tools – where innovation meets precision and efficiency.

Buy

In Stock

Product & Service

New

API

Air Freight

Safe-T-Whip™ Continuous RD-XLong 30’-9”

RD-XLongIntroducing Safe-T-Whip™ Continuous RD-XLong 30’-9”: Unmatched Safety and Reliability for Extended Restraint Applications At Safe-T-Whip & Restraints Inc., safety is our unwavering commitment. We are proud to present our latest innovation - the Safe-T-Whip™ Continuous RD-XLong 30’-9”. Designed for extended restraint applications, this safety whip offers unparalleled protection and reliability for pressurized pipe fittings in the oilfield. Unmatched Safety Restraint System: The Safe-T-Whip™ Continuous RD-XLong 30’-9” is a safety restraint system specially designed to contain uncontrolled movement on both sides of a pipe union during sudden and total failure. By creating a choke on either side of a potential rupture, it effectively reduces in-line flowline movement as well as lateral movement, mitigating dangerous impacts. Engineered for Maximum Protection: The Safe-T-Whip™ Continuous system offers end-to-end restraint of flowlines for all lengths of pipe sections, swivels, and joints. Each section is secured by both the upstream and downstream sections of the flowline, ensuring comprehensive protection in the event of failure. Proper evaluation of the piping system is crucial to ensure adequate anchoring both upstream and downstream, enhancing safety. Certified for Uncompromising Quality: Safety is paramount, and that's why all Safe-T-Whip™ Restraints and Anchors undergo rigorous testing and certification to meet the highest industry standards. Our commitment to quality ensures that you receive a safety restraint system you can trust. Versatility and Flexibility: The Safe-T-Whip™ Continuous RD-XLong 30’-9” is designed for use on 2, 3, and 4-inch iron 1502 hammer union pipes, with recommended pressures ranging from 2,000psi to 15,000psi. Its versatility makes it ideal for various flowline configurations, ensuring superior protection for your operations. Enhanced Flowline Safety: Once installed correctly, the Safe-T-Whip™ Continuous RD-XLong 30’-9” is designed to limit unsafe flowline movement throughout the entire linear series of a flowline. With Safe-T-Whip™ Continuous RD-XLong 30’-9”, you can rest assured that your operations are safeguarded from catastrophic failures. The Ultimate Safety Restraint: SW-RD-XLong 30’-9” Safe-T-Whip™ Continuous is the ultimate safety restraint for extended applications. Trust in the power of Safe-T-Whip™ to safeguard your workforce, equipment, and operations. With Safe-T-Whip & Restraints Inc., safety is never compromised. Invest in Unparalleled Safety: SW-RD-XLong 30’-9” Safe-T-Whip™ Continuous is the pinnacle of safety restraints for extended applications. Secure your Safe-T-Whip™ Continuous RD-XLong 30’-9” today. Keep your operations safe with Safe-T-Whip & Restraints Inc., your trusted partner in safety.

Buy

In Stock

Product & Service

New

API

Air Freight

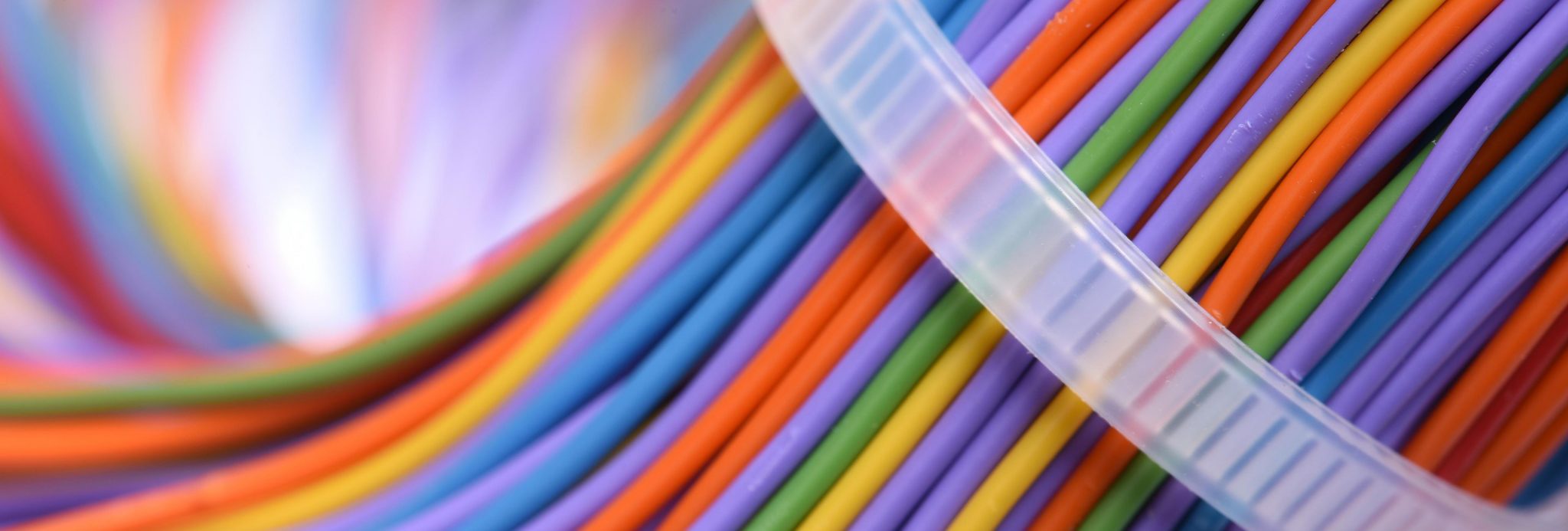

Fiber Network Backbone Installation

![]() Nulux Networks in Edmonton

Nulux Networks in Edmonton

Illuminating the Pathway to Enhanced Connectivity with Nulux: Pioneering Fiber Network Backbone Installation for the Oil & Gas Sector In the intricate labyrinth of the energy sector, wherein seamless data transmission forms the spinal cord of operational efficacy, establishing a robust, secure, and unfettered network backbone becomes imperative. At Nulux Network Solutions, our objective transcends beyond offering mere solutions; we are your partners in navigating through the convoluted pathways of data connectivity and communication within the oil and gas industry, ensuring that the artery of your operations pulsates with vigor, reliability, and sustainability. Sustaining the Future with Fiber Optics Nulux emerges as a beacon of sustainable advancements, offering an array of products, solutions, and services that cascade across the entirety of the energy value chain. We are steadfast in our commitment to guiding our partners in the oil and gas industry towards a future that not only resonates with sustainability but is also interwoven with technological prowess and innovation. Our Fiber Optic solutions symbolize this commitment, ensuring your journey towards a more sustainable future is always illuminated by the consistent, reliable, and efficient transmission of data. The Nulux Fiber Network Backbone Installation The oil and gas industry, characterized by its voluminous data generation, necessitates a network backbone that can shoulder the hefty demands of data transmission with unbridled efficiency and security. Our Fiber Network Backbone Installation service is not merely a technological provision but an embodiment of our expertise, experience, and dedication to ensuring your operations are always in sync with the digital pulse of the industry. Reliable Data Transmission: An uninterrupted flow of operational data is ensured, empowering your operations with real-time analytics, diagnostics, and vital decision-driving data. Fortified Security: Guarding your data against potential breaches and vulnerabilities with a fiber network that is securely fortified, ensuring a safe and secure environment for your data to traverse. Scalability: Our fiber network infrastructure scales in tandem with your operational expanse, ensuring that as your data demands burgeon, our network is always a step ahead in meeting those requirements with equal efficiency and reliability. A Tapestry of Operational Excellence Our Fiber Network Backbone Installation forms the intricate tapestry that interlaces your operational nodes, ensuring that the voluminous data generated is seamlessly integrated, conveyed, and utilized, forming the substrate upon which vital operational strategies and decisions are cultivated and realized. Safeguarding Your Data, Ensuring Its Journey is Unhindered At Nulux, we ensure that the conduit through which your data traverses is not merely operationally optimized but also securely shielded against potential cyber threats and vulnerabilities, fortifying your operational data against breaches and ensuring it navigates through a secure pathway. Join Hands with Nulux Embark on a journey where your operational data is not merely transmitted but is safeguarded, scrutinized, and utilized to shape a future wherein your operations echo with sustainability, operational excellence, and technological advancement. With our Fiber Network Backbone Installation, steer through the digital realms of the oil and gas industry with Nulux, where every bit of data, every decision, and every operational stride is backed by the stalwart reliability and security of our fiber-optic solutions. In a realm where data propels decisions, ensuring its secure, efficient, and unfettered transmission is paramount. Traverse with Nulux, where your data is not merely communicated but empowers your operations towards a future where every decision is data-driven, every operation is efficient, and your journey towards sustainability is continually illuminated by the steadfast glow of our solutions. Your journey towards an operationally efficient and sustainable future begins with Nulux. Let’s navigate through the digital corridors of the oil and gas industry together, ensuring your data navigates through the most secure, reliable, and efficient pathways, crafting a future where technology and sustainability converge to form a symphony of operational excellence. Let’s craft this future, together, with Nulux.

Service

In Stock

Service

New

ISO

MS-251EC Extraction Condensing Steam Turbine

Multistage Turbine![]() Kessels Engineering Works Pvt. Ltd. in New Delhi

Kessels Engineering Works Pvt. Ltd. in New Delhi

Unlock Unparalleled Efficiency with the Kessels MS-251 EC Extraction Condensing Steam Turbine: Where Precision Meets Power In the ever-evolving landscape of the oil and gas industry, precision, reliability, and sustainability reign supreme. Kessels Steam Turbines is proud to introduce the MS-251 EC Extraction Condensing Steam Turbine, a technological marvel that redefines excellence in steam turbine technology. Mastery of Extraction Condensing Turbines Extraction condensing turbines are the backbone of industries demanding a constant pressure steam flow for diverse processes. The MS-251 EC shares structural characteristics with condensing turbines, making it the ideal choice when you need a dependable source of constant pressure steam for your operations. Efficiency Perfected What sets the MS-251 EC apart is its remarkable capability to inject low-pressure steam from the second admission valve chest. This ingenious feature optimizes the utilization of available plant resources to meet power demands, making our turbine an indispensable asset in co-generation scenarios. Steady Power, Unwavering Performance In co-generation settings, where maintaining a consistent power supply despite fluctuations in process steam demands is paramount, the MS-251 EC excels. This turbine ensures your power generation remains steady, providing a rock-solid foundation for your operations. Ultimate Versatility At Kessels, we understand that each industry has unique needs. In some cases, you may require both bleed and controlled extraction steams from the condensing turbine. Our MS-251 EC is designed to meet these demands, offering the flexibility of a bleed cum extraction condensing turbine. Why Choose Kessels? Choosing Kessels Steam Turbines isn't just a business decision; it's a commitment to excellence, innovation, and reliability. Our MS-251 EC Extraction Condensing Steam Turbine embodies these principles, offering you: Unmatched Efficiency: Harness low-pressure steam resources efficiently, reducing energy waste and maximizing productivity. Reliability Beyond Question: Crafted with precision and subjected to rigorous testing, our turbine ensures uninterrupted operations, even in the most demanding industrial environments. Consistent Power Supply: Experience uninterrupted power generation, regardless of variations in process steam demands, ensuring your operations run seamlessly. Exceptional Versatility: Adapt effortlessly to your unique requirements, whether you need bleed or controlled extraction steams, with the confidence that Kessels' expertise provides. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive landscape of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-251 EC Extraction Condensing Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight