Tubing Hanger Coupling - 4 ½” to 2 3/8”

Tubing Hanger Coupling

Also known as:

Tubing Coupling, Tubing Hanger Adapter

Tubing Hanger Coupling - 4 ½” to 2 3/8”

Tubing Hanger Coupling

Also known as:

Tubing Coupling, Tubing Hanger AdapterBuy

Made to Order

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

4 - 6 WeeksNote:

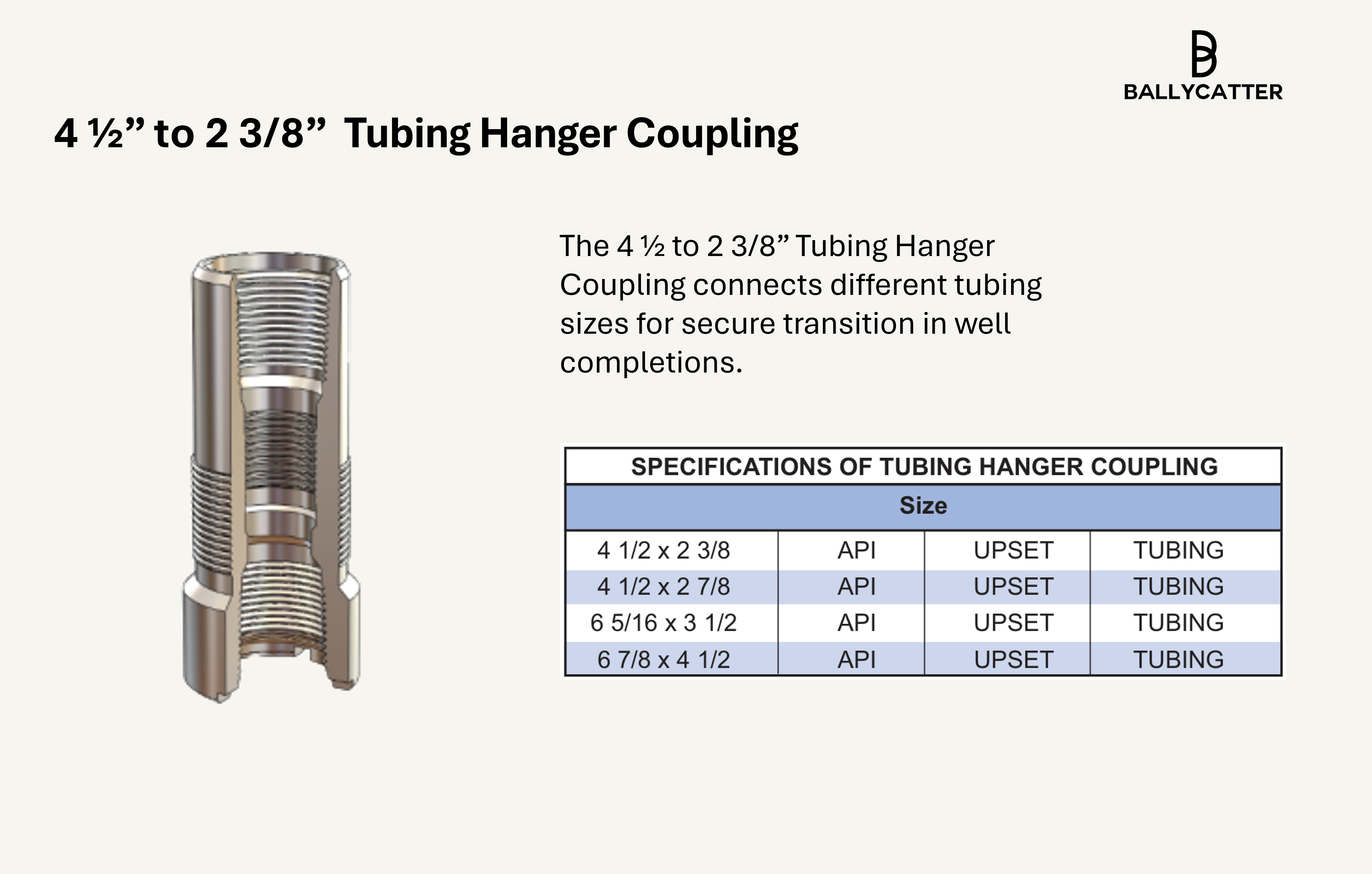

The 4 ½ to 2 3/8” Tubing Hanger Coupling connects different tubing sizes for secure transition in well completions.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The 4 ½ to 2 3/8” Tubing Hanger Coupling is a specialized connection component used in wellhead systems to join two different sizes of upset tubing. It is typically used in combination with a tubing hanger spool, wrap-around hanger, and compatible tubing spool, forming part of a modular wellhead completion assembly.

This coupling enables the tubing string to be secured in place without rotating the Christmas tree during installation, thanks to a union nut design that simplifies the connection process. It also includes threading for a back pressure valve, which helps control wellbore pressure during installation or intervention. Both the top and bottom threads can be customized to suit specific well configurations, making it adaptable for various field applications.

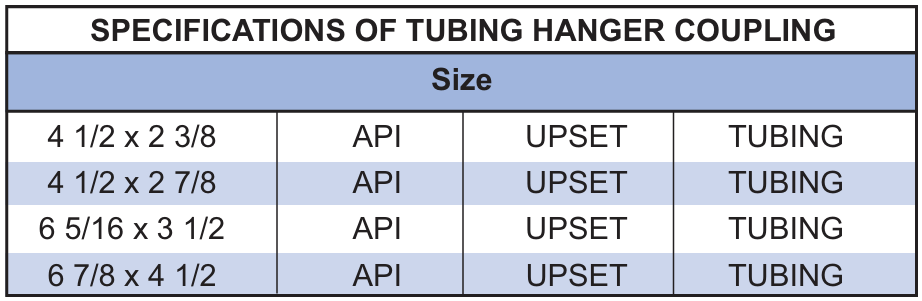

Technical Specifications

| Tubing Size (Top) | 4 ½” |

| Tubing Size (Bottom) | 2 3/8” |

| Standard | API |

| Tubing Type | Upset Tubing |

| Installation | Union nut, no Xmas tree rotation |

| Threading | Customizable top & bottom threads |

| Features | Threaded for back pressure valve |

| Usage | Works with tubing hanger spools |

| Material | Alloy steel |

| Compatibility | Fits standard tubing hanger systems |

Features and Benefits

- Connects 4½” and 2⅜” upset tubing sizes.

- Union nut design allows installation without rotating the Christmas tree.

- Supports operational efficiency and well control through adaptable design.

- Designed for high-pressure, high-temperature well environments.

- Compatible with tubing hanger spools, PTHSW, and PTHS-type tubing spools.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The 4 ½” x 2 3/8” tubing hanger coupling is a specialized downhole component designed to connect two different sizes of upset tubing within a wellhead assembly. Upset tubing refers to tubing that has thicker, reinforced sections at the ends—called “upsets”—which strengthen the threaded connections and help withstand the mechanical stresses and high pressures encountered during well operations. This coupling provides a secure and pressure-tight transition between a larger 4 ½-inch tubing hanger and a smaller 2 3/8-inch production tubing string, enabling effective management of wellbore fluids and maintaining pressure containment.

Engineered to integrate seamlessly with tubing hanger spools, wrap-around tubing hangers (PTHSW), and ‘PTHS’-type tubing spools, this coupling forms part of a modular wellhead completion system. Its union nut design allows installation by screwing the coupling in place without rotating the Christmas tree, simplifying assembly and reducing the risk of damage during installation.

Both the top and bottom ends of the coupling are threaded to customer specifications, offering flexibility for various well configurations and allowing the installation of back pressure valves to maintain well control during operations. Manufactured to API standards and constructed from high-grade materials, the coupling delivers durability and reliable performance in demanding downhole environments characterized by high pressure, temperature, and corrosive fluids.

By facilitating a smooth and strong size transition between different tubing strings, the 4 ½” x 2 3/8” tubing hanger coupling supports well integrity, operational efficiency, and safety throughout oil and gas production.

Engineering Data