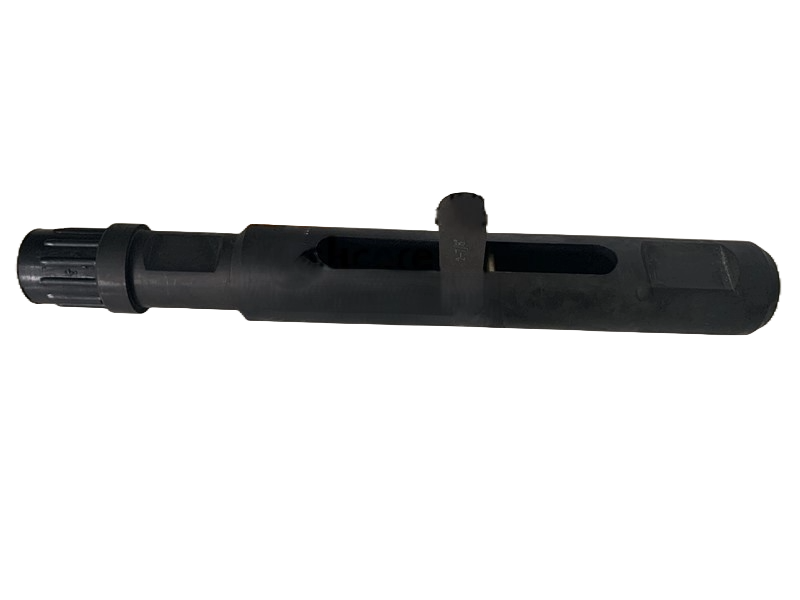

4” Tubing End Locator

Tubing End Locator

Also known as:

TEL, Mechanical Tubing End Locator

4” Tubing End Locator

Tubing End Locator

Also known as:

TEL, Mechanical Tubing End LocatorBuy

Made to Order

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

4 - 6 WeeksNote:

The 4” Tubing End Locator is designed for larger tubing, ensuring precise end detection in bigger wellbores.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

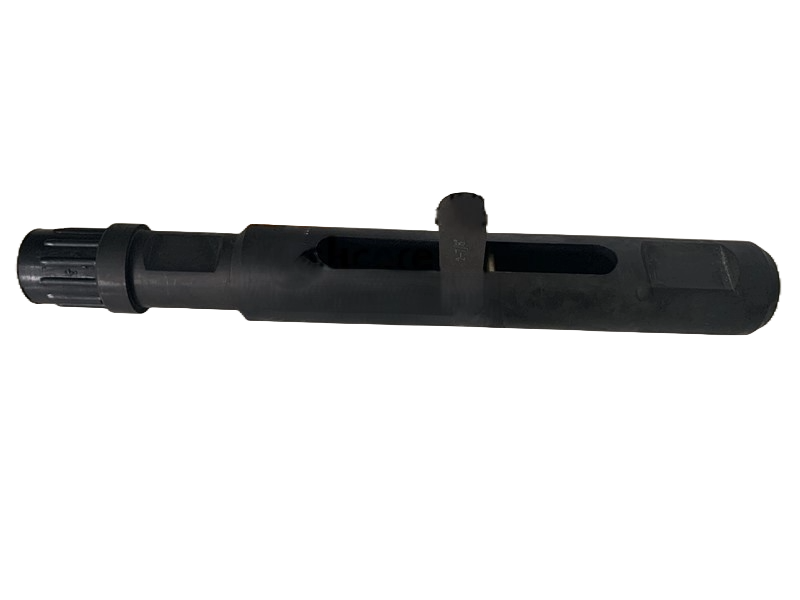

The 4” Tubing End Locator is engineered to detect the bottom of 4-inch production tubing during well intervention procedures. Its spring-loaded mechanism delivers a dependable mechanical indication when the tubing end is reached, allowing precise positioning of downhole tools.

With a compact design tailored for larger tubing sizes and standard threaded connections. It offers a simple, reliable solution for confirming tubing depth, enhancing the accuracy and safety of oil and gas servicing operations.

Technical Specifications

| Size | 4” |

| Max O.D. | 3.750” |

| F/N O.D. | 2.312” |

| Top Conn. Pin | 1-9/16 – 10 N |

| Bottom Conn. Box | 1 - 11.1/2 NPT |

| Part No. | 423746 |

| Material | Alloy steel |

| Compliance | API |

| Operating Tubing Size | 2” to 2½” |

| Tool Function | Locates the end of production tubing. |

Features and Benefits

- Supports operations in wells with larger tubing.

- Compatible with common slickline, wireline, and coiled tubing toolstrings.

- Provides a reliable mechanical signal upon reaching the tubing end.

- Withstands high pressure, elevated temperatures.

- Enables precise placement of downhole tools.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The 4” Tubing End Locator is designed specifically for use with larger production tubing strings common in wells that require greater flow capacity or enhanced mechanical strength. This size is typically found in wells with higher production rates or more demanding operational requirements, where accurate depth confirmation becomes even more critical.

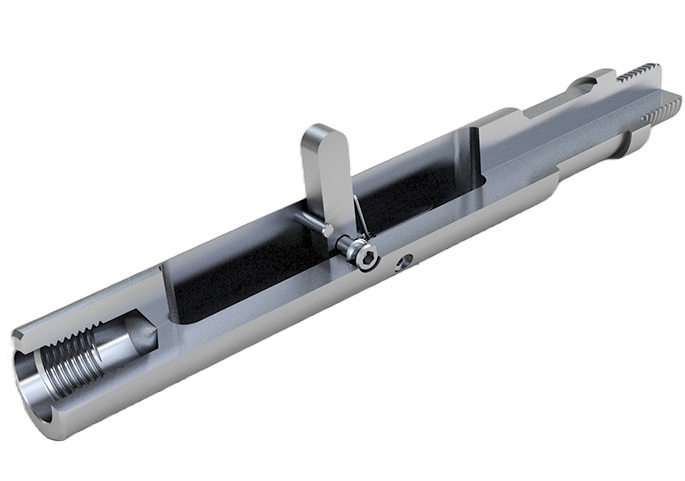

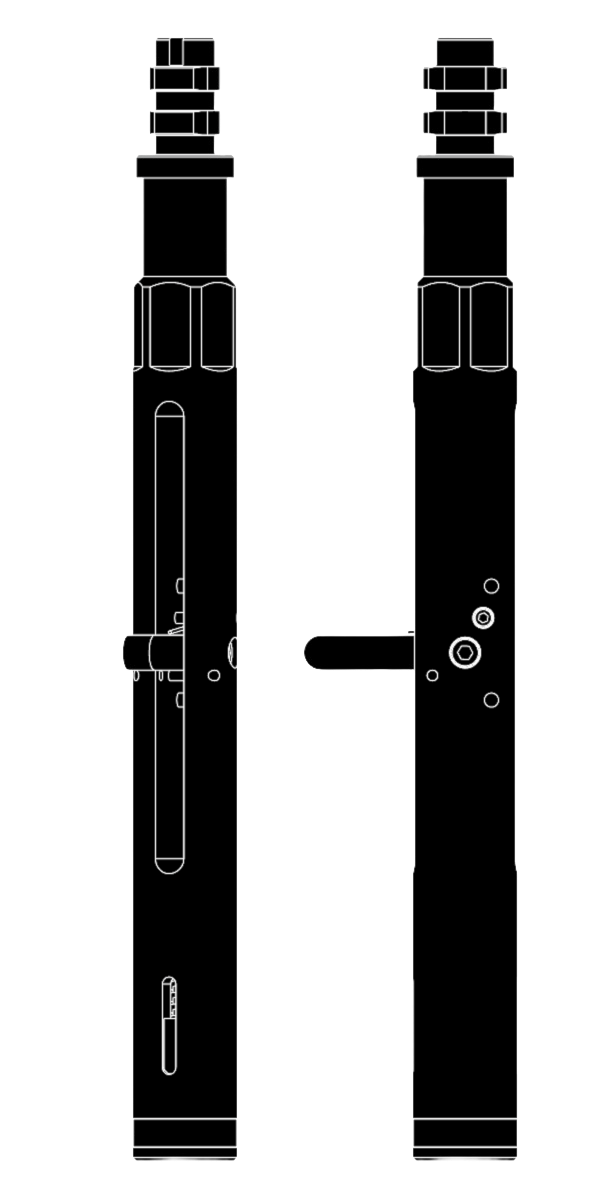

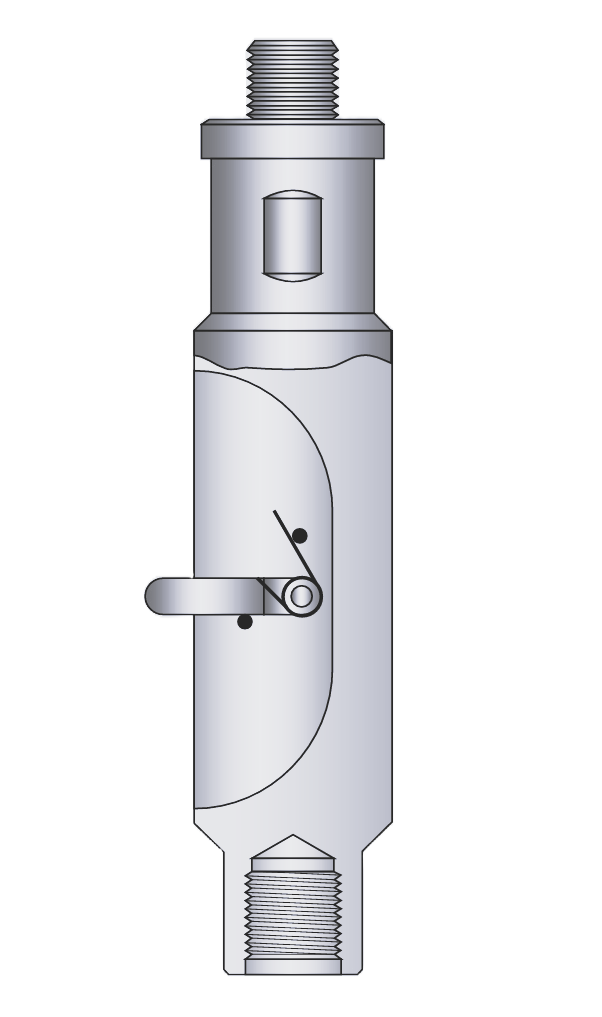

This model is specifically sized for 4-inch outer diameter tubing, featuring a maximum outside diameter that fits comfortably within the tubing’s internal dimensions. This sizing ensures that the locator can move smoothly without obstruction while maintaining effective contact to detect the tubing end. The core mechanism involves a spring-loaded finger that extends outward upon contacting the tubing bottom. This movement translates into a tactile signal felt at the surface, eliminating the need for complex electronic systems and reducing the risk of failure in harsh downhole environments.

Equipped with standardized threaded connections—commonly a 1-9/16 - 10 UN pin on the top and a 1 - 11 ½ NPT box on the bottom—the tool integrates easily into typical slickline, wireline, or coiled tubing toolstrings. The fully mechanical design enhances reliability, making it well-suited for use in conditions of high pressure, elevated temperatures, and corrosive fluids often found in oil and gas wells.

The 4” Tubing End Locator is especially valuable in wells with larger tubing sizes where accurate depth confirmation is critical to avoid operational errors. By providing a straightforward and dependable method to locate the tubing end, it supports safe and efficient well intervention, helping to reduce downtime and operational risks.

Engineering Data