Fuel Nozzle for LM2500 Gas Turbine

Fuel Nozzle

Also known as:

Spray Tip, Swirler

Fuel Nozzle for LM2500 Gas Turbine

Fuel Nozzle

Also known as:

Spray Tip, SwirlerBuy

Made to Order

Product

Price:

Request for QuoteShipping:

Air freightNote:

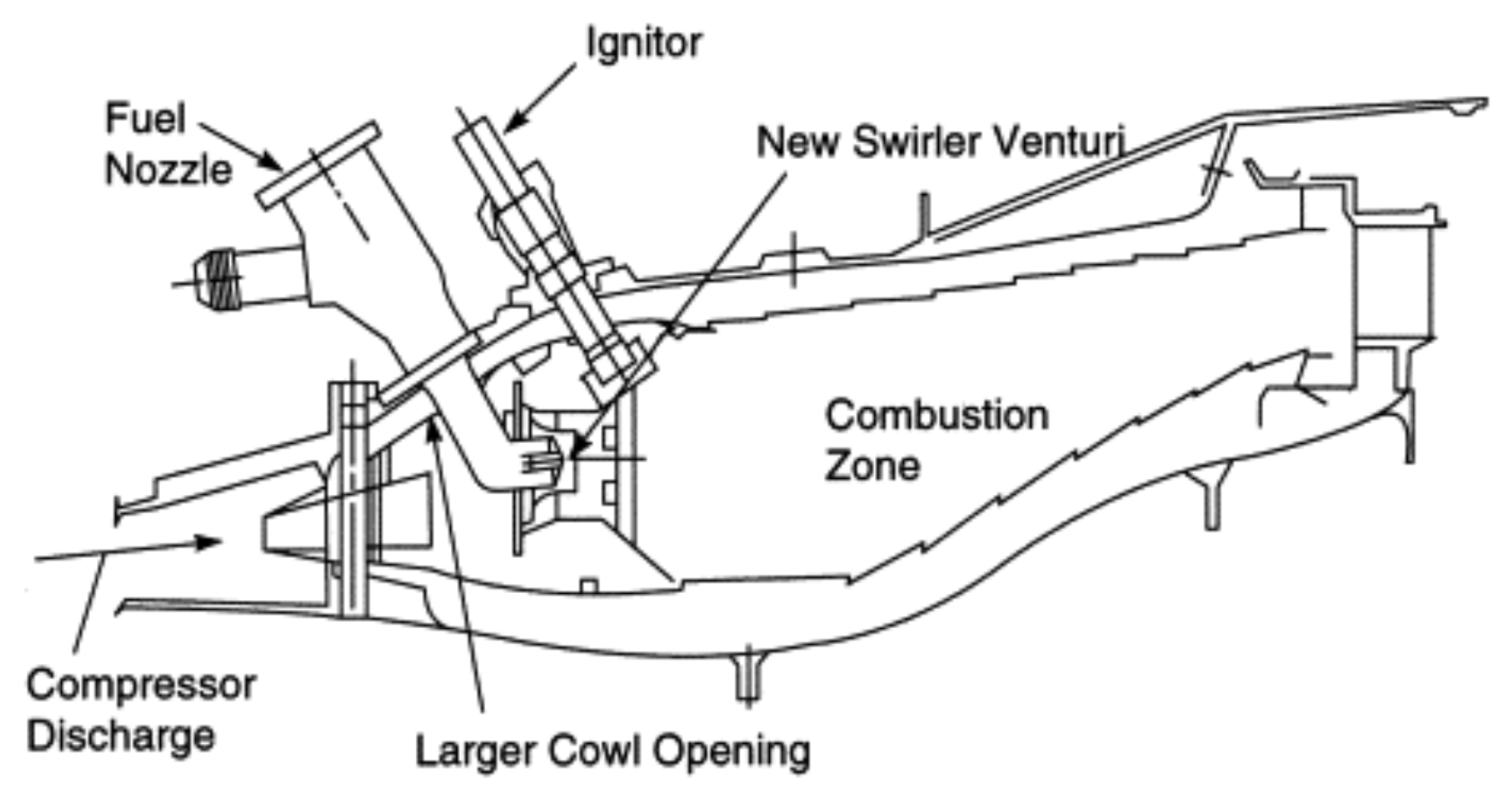

The 2-cup fuel nozzle sprays and atomizes fuel into the combustion chamber for efficient ignition. It ensures consistent fuel delivery to support optimal turbine performance.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

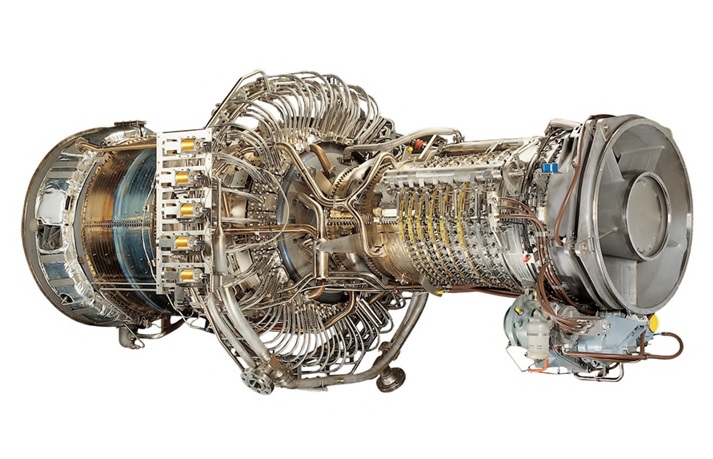

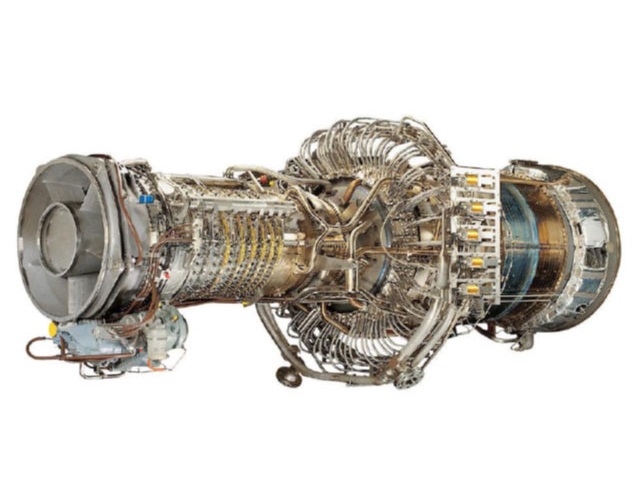

The 2-cup fuel nozzle is an essential part of gas turbine engines, responsible for injecting and atomizing fuel into the combustion chamber. In oil and gas operations, it ensures consistent fuel delivery and optimal combustion performance, contributing to efficient turbine operation, reduced emissions, and reliable energy output in harsh industrial environments.

Technical Specifications

| Part Number | L47197P05 |

| Nozzle Type | 2-cup fuel nozzle |

| Application | LM2500 Gas Turbine |

| Flow Path | Dual-flow / dual-cup |

| Material | High-temperature alloy |

Features and Benefits

- Dual passages ensure even fuel distribution.

- Improved combustion efficiency.

- Minimizes hot spots and extends combustion hardware life.

- Compact, durable build.

- Enhances mixing with air for efficient combustion.Enhances mixing with air for efficient combustion.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The 2-cup Fuel Nozzle is a precision-engineered component used in gas turbines, specifically in the oil and gas industry. Its primary function is to inject liquid fuel into the combustion chamber in a fine, atomized spray, allowing for optimal mixing with air and efficient ignition. This ensures stable combustion, better fuel efficiency, and reduced emissions—key performance factors in industrial turbine applications.

The “2-cup” design refers to the nozzle’s dual flow passages, which help balance fuel distribution across the combustion zone. This promotes more uniform flame stability and lowers the risk of hot spots that can cause thermal stress to the turbine hardware. The nozzle is typically used on “base” engines and is suited for continuous-duty operations.

The L47197P05 variant is known for its compatibility with LM2500 turbine configurations and is built to endure harsh operating environments. It features durable materials and a design that withstands high temperatures and pressures commonly found in oil and gas turbine systems.

Engineering Data