Tubing Hanger Coupling – 6 7/8” to 4 1/2”

Tubing Hanger Coupling

Also known as:

Tubing Coupling, Tubing Hanger Adapter

Tubing Hanger Coupling – 6 7/8” to 4 1/2”

Tubing Hanger Coupling

Also known as:

Tubing Coupling, Tubing Hanger AdapterBuy

Made to Order

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

4 - 6 WeeksNote:

The 6 7/8 x 4 1/2” Tubing Hanger Coupling provides a strong, pressure-rated connection between large wellhead outlets and 4 1/2” production tubing, ideal for high-flow applications.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

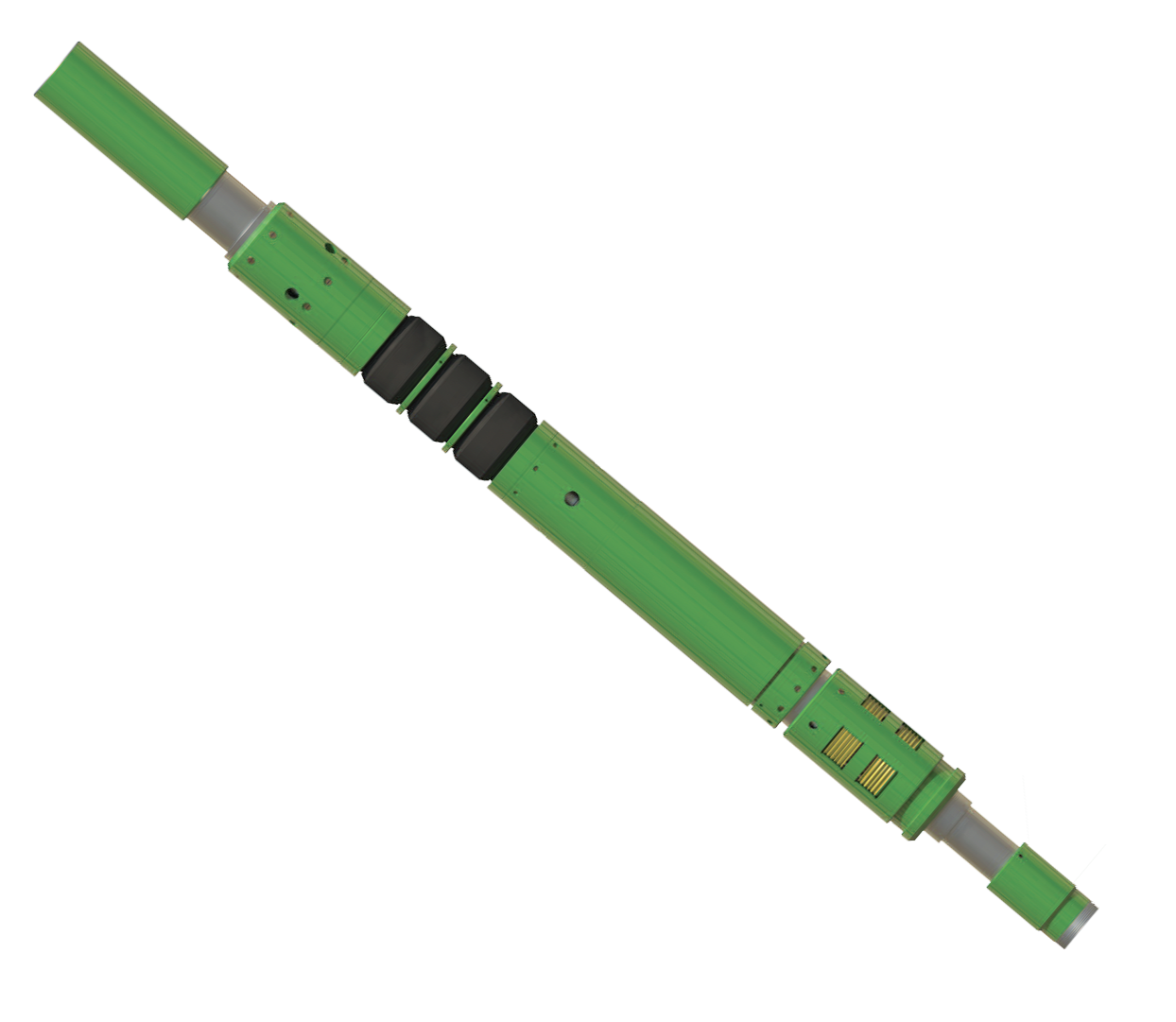

The 6 7/8 x 4 1/2” Tubing Hanger Coupling is used in wellhead systems where a larger outlet is connected to a 4 1/2” upset tubing string. This size combination is often selected when a well requires higher flow capacity while maintaining compatibility with standard tubing sizes. The larger 6 7/8” connection allows integration with heavy-duty hanger spools or equipment, while the 4 1/2” tubing supports strong mechanical properties and internal pressure ratings.

The coupling is designed to accept a back pressure valve and can be threaded on both ends to match specific installation requirements. Its construction supports stable sealing and load transfer between casing and tubing components. This size is typically chosen in completions where flow volume, pressure containment, and structural strength are critical considerations.

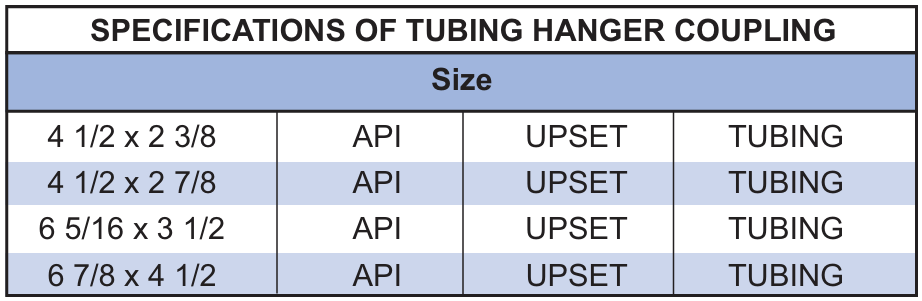

Technical Specifications

| Tubing Size (Top) | 6 7/8” |

| Tubing Size (Bottom) | 4 1/2” |

| Standard | API |

| Tubing Type | Upset Tubing |

| Installation | Union nut, no Xmas tree rotation |

| Threading | Customizable top & bottom threads |

| Features | Threaded for back pressure valve |

| Usage | Works with tubing hanger spools |

| Material | Alloy steel |

| Compatibility | Fits standard tubing hanger systems |

Features and Benefits

- Connects large-diameter wellhead outlets to 4 1/2” upset tubing.

- Allows installation without rotating the Christmas tree or upper assembly.

- Meets recognized oil and gas equipment standards.

- Designed for tubing with thickened ends to enhance thread strength.

- Supports safe, pressure-sealed transitions between wellhead and tubing system.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

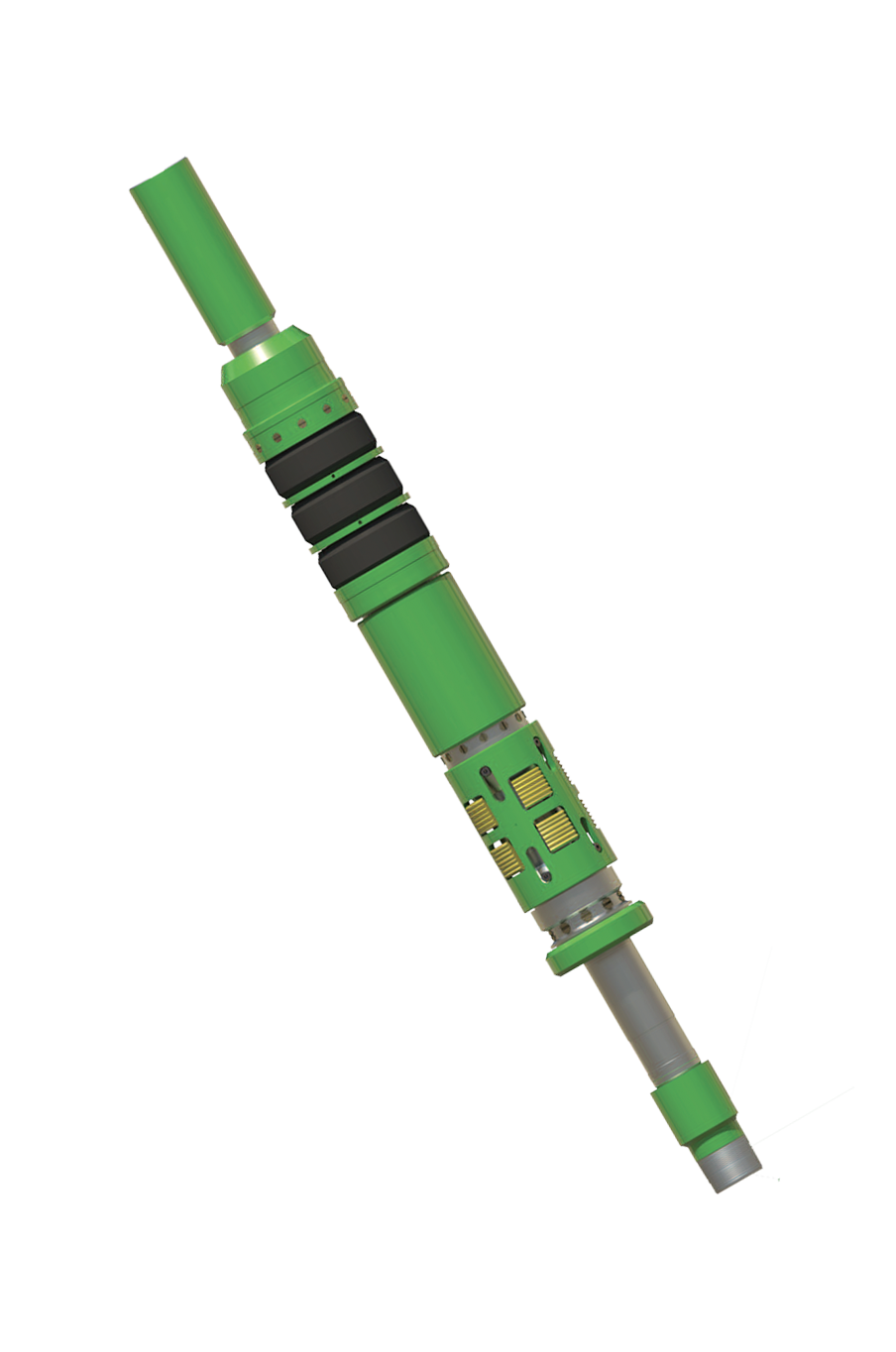

The 6 7/8” to 4 1/2” Tubing Hanger Coupling is a specialized connection used in oil and gas wellhead systems to join a large-diameter casing outlet—6 7/8 inches—with 4 1/2-inch upset production tubing. This configuration is typically applied in high-flow and high-pressure wells where maintaining structural integrity and maximizing production efficiency are critical.

The coupling serves as a transition component within a tubing hanger assembly, allowing the tubing to be securely suspended in the wellhead without the need to rotate the Christmas tree during installation. This is made possible by its union nut design, which permits tightening from the side, simplifying assembly in tight or restricted spaces.

The 4 1/2” end is designed for upset tubing, which features thickened ends to provide stronger threaded connections capable of withstanding axial loads and internal pressure. This enhances the mechanical performance of the joint, reduces the risk of fatigue failure, and helps maintain seal integrity over long service periods. The coupling is also threaded to accept a back pressure valve, an essential feature that provides well control during servicing, installation, or emergency conditions.

To meet a variety of operational needs, the top and bottom threads can be customized according to site or equipment specifications. The coupling is typically manufactured from high-strength, corrosion-resistant materials and in compliance with industry standards such as API 5CT, ensuring it performs reliably under harsh downhole conditions.

Overall, the 6 7/8 x 4 1/2” Tubing Hanger Coupling is chosen for its ability to support larger bore wellhead designs while maintaining compatibility with standard tubing strings. It offers a dependable solution in completions where mechanical strength, pressure containment, and ease of assembly are priorities.

Engineering Data