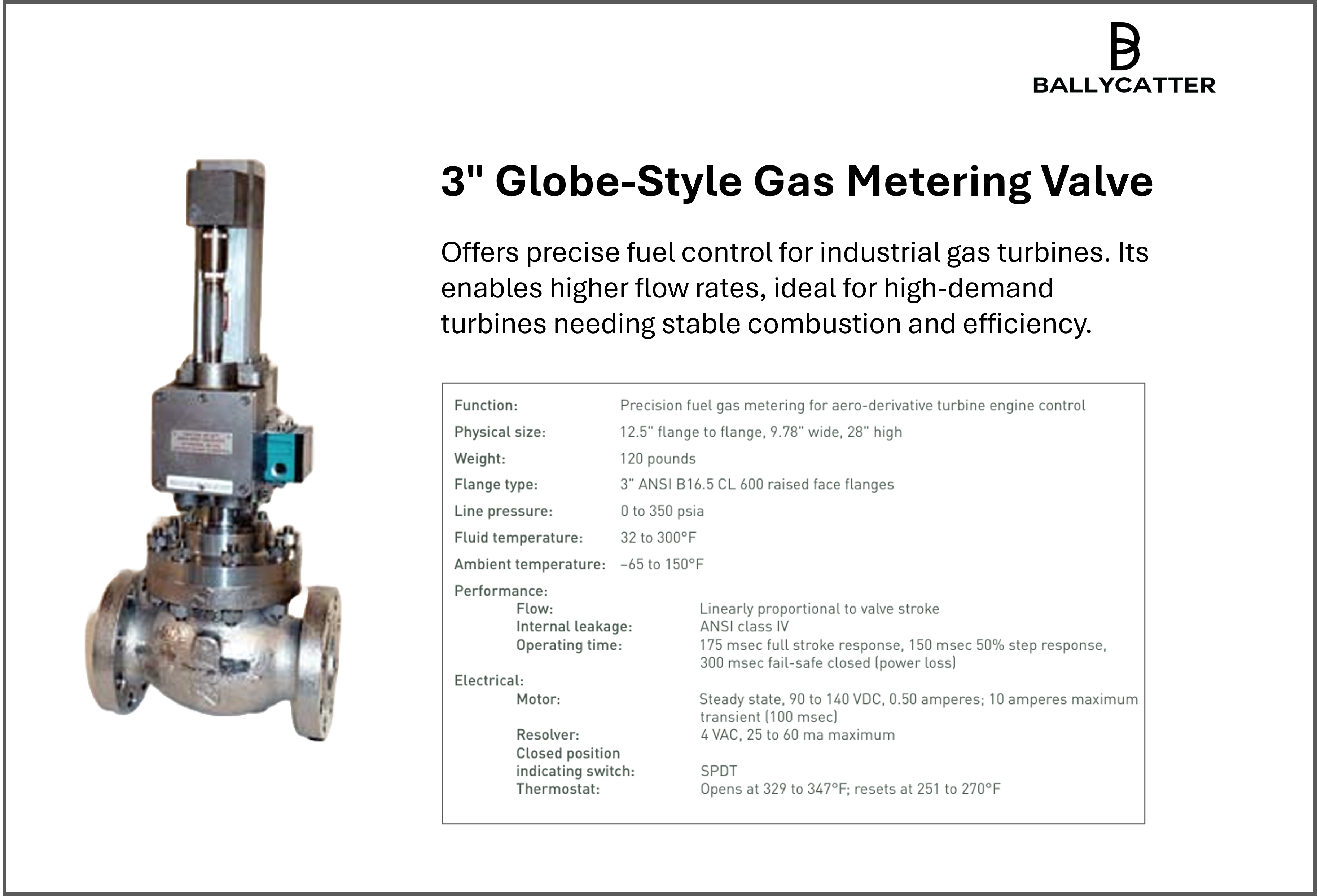

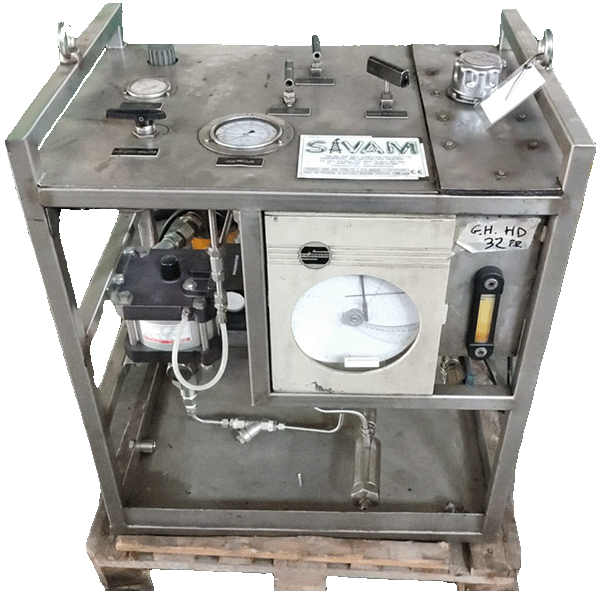

3" Globe-Style Gas Metering Valve

Gas Metering Valve

Also known as:

Fuel Metering Valves

3" Globe-Style Gas Metering Valve

Gas Metering Valve

Also known as:

Fuel Metering ValvesBuy

Made to Order

Product

Price:

Request for QuoteShipping:

Air freightDelivery Time:

2 WeeksNote:

The 3” Globe-Style Gas Metering Valve offers precise fuel control for industrial gas turbines. Its enables higher flow rates, ideal for high-demand turbines needing stable combustion and efficiency.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

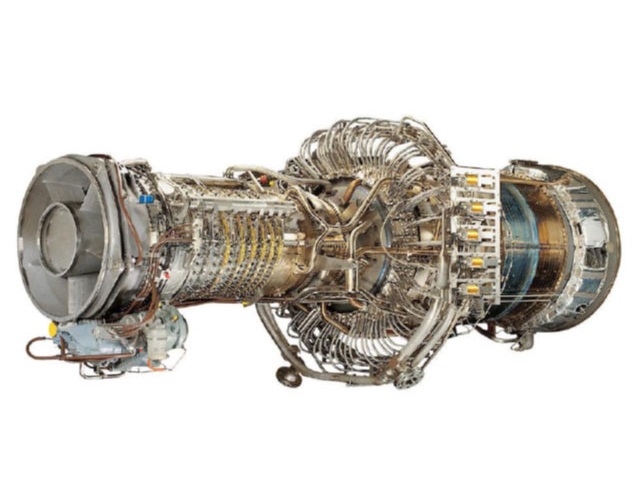

The 3” Globe-Style Gas Metering Valve is built to control gas fuel flow in industrial gas turbines commonly used in oil and gas operations. Its globe-style design provides smooth, precise regulation of fuel, ensuring the correct fuel-to-air ratio for efficient combustion. This helps maintain stable turbine output, reduce emissions, and improve fuel efficiency—critical in demanding field environments. The valve is suited for high-capacity systems where consistent, reliable performance directly supports operational uptime and compliance with environmental targets.

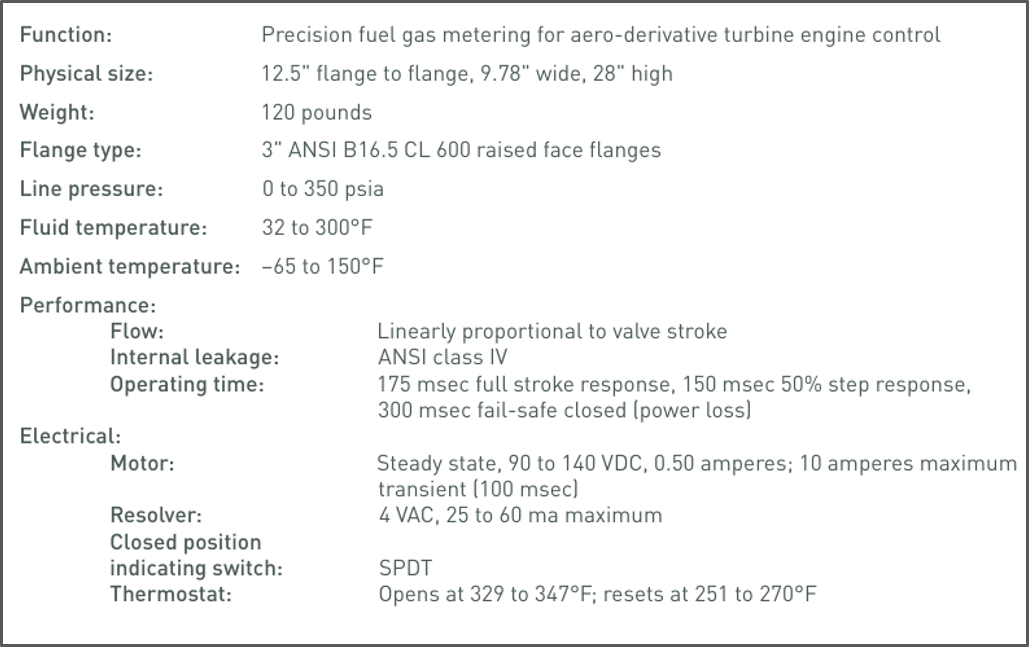

Technical Specifications

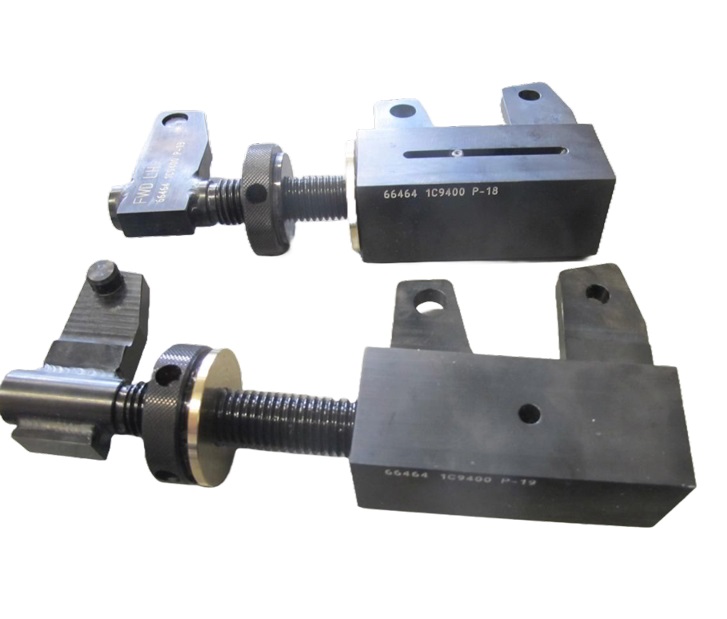

| Physical Size | 12.5” flange to flange, 9.78” wide, 28” high |

| Weight | 120 pounds |

| Flange Type | 3” ANSI B16.5 CL 600 raised face flange |

| Line Pressure | 0 to 350 psia |

| Fluid Temperature | 32 to 300°F |

| Ambient Temperature | -65°F to 150°F |

| Flow | Linearly proportional to valve stroke |

| Internal Leakage | ANSI class IV |

| Resolver | 4 VAC, 25 to 60 ma maximum |

| Closed Position Indicating Switch | SPDT |

Features and Benefits

- No maintenance required under normal conditions.

- Used on both DLE and SAC turbine engines.

- All stainless steel valve.

- Explosion proof design.

- High speed brushless DC servo motor performance.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The 3” Globe-Style Gas Metering Valve is designed to deliver accurate and consistent fuel control in industrial gas turbines, including both Dry Low Emissions (DLE) and Single Annular Combustor (SAC) engine types. This valve ensures that the correct amount of gas fuel is metered into the engine based on real-time operating conditions—essential for achieving stable combustion, optimal turbine performance, and reduced emissions.

With an accuracy of ±3% of flow point and a full-stroke response time of 175 milliseconds, it supports precise adjustments to the fuel-to-air ratio, even under fluctuating load conditions. This level of performance is critical for maintaining turbine efficiency, lowering NOx and CO emissions, and supporting regulatory compliance.

The globe-style design allows for smooth fuel flow control, making it ideal for high-capacity, high-pressure turbine applications, such as those found in the oil and gas industry. Built to withstand extreme temperatures and pressures, the valve is available with certifications such as ATEX Zone 1 and 2, PED, UL, and NEC Class 1, ensuring safe operation in hazardous environments.

This metering valve supports modern turbine control systems and is part of a generation of components that prioritize long-term reliability, reduced maintenance needs, and consistent field performance.

Engineering Data