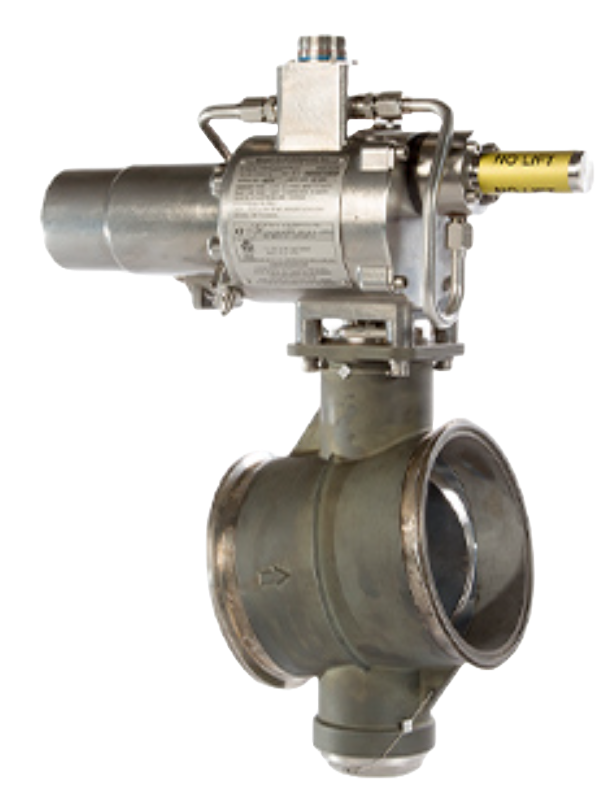

6″ Butterfly Bleed Air Valve

Butterfly Bleed Air Valve

Also known as:

Bleed Air Valve

6″ Butterfly Bleed Air Valve

Butterfly Bleed Air Valve

Also known as:

Bleed Air ValveBuy

Made to Order

Product

Price:

Request for QuoteShipping:

Air freightDelivery Time:

2 WeeksNote:

The 6″ Butterfly Bleed Air Valve controls high-volume bleed air flow to protect and optimize large gas turbines like the LM2500.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

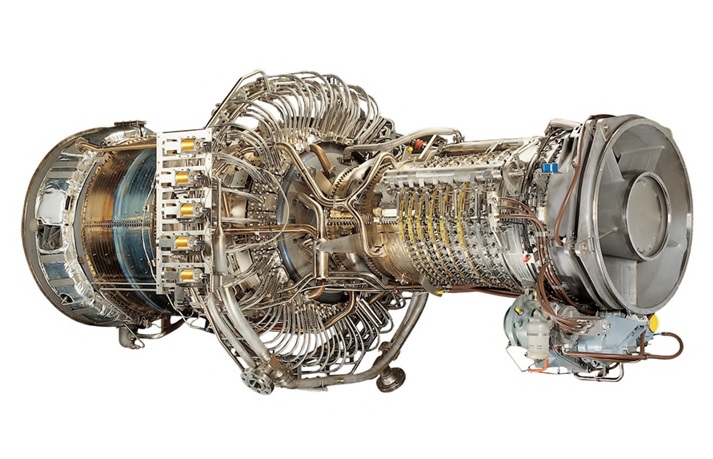

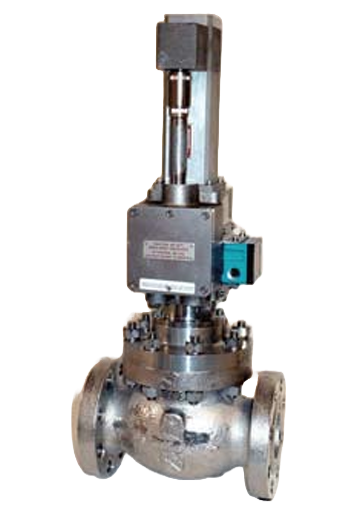

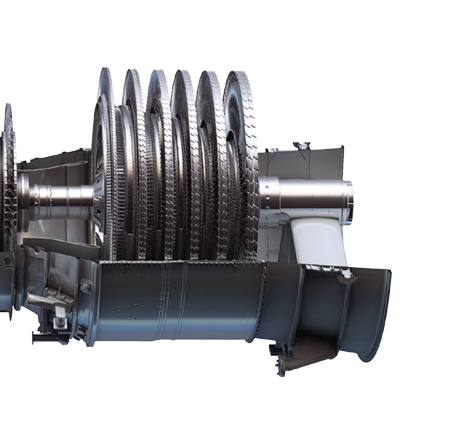

The 6″ Butterfly Bleed Air Valve is designed to manage high volumes of bleed air in large gas turbines like the LM2500. It controls airflow to reduce pressure and temperature inside the turbine, preventing damage and ensuring efficient performance.

Operators choose this valve when they need a robust solution for turbines with higher capacity or more demanding operating conditions, helping maintain safety, reliability, and longer equipment life.

Technical Specifications

| Flange Connections | AS1895 |

| Function | Compressor bleed regulation |

| Inlet Pressure | 0 to 250 psia max |

| Bleed Air Temperature | 745°F max |

| Weight | 55 lbs |

| Ambient Temperature | -65°F to 350°F |

| Operating Speed | 320 msec full stroke operation |

| Internal Leakage | 6.0 ppm max at 200 psia |

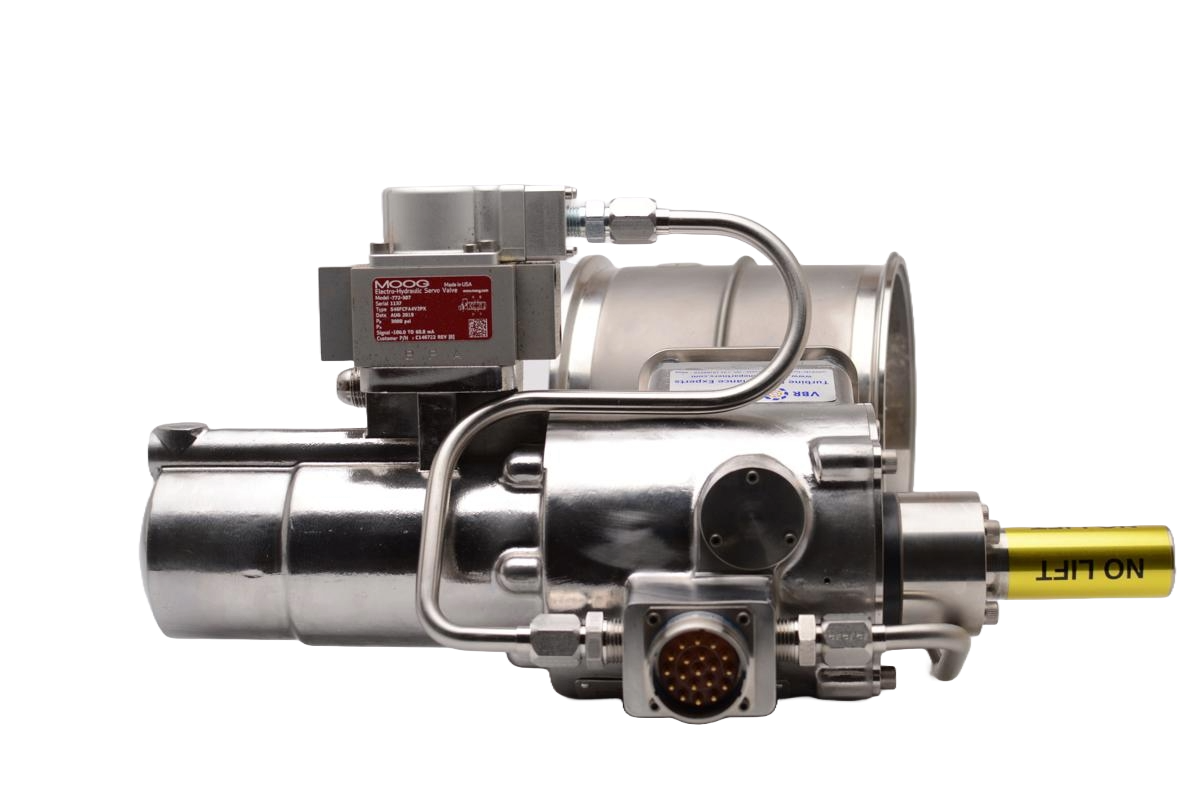

| Servo Valve | -100 to +60 mA operating current |

| Electrical Connector | M83723 type |

Features and Benefits

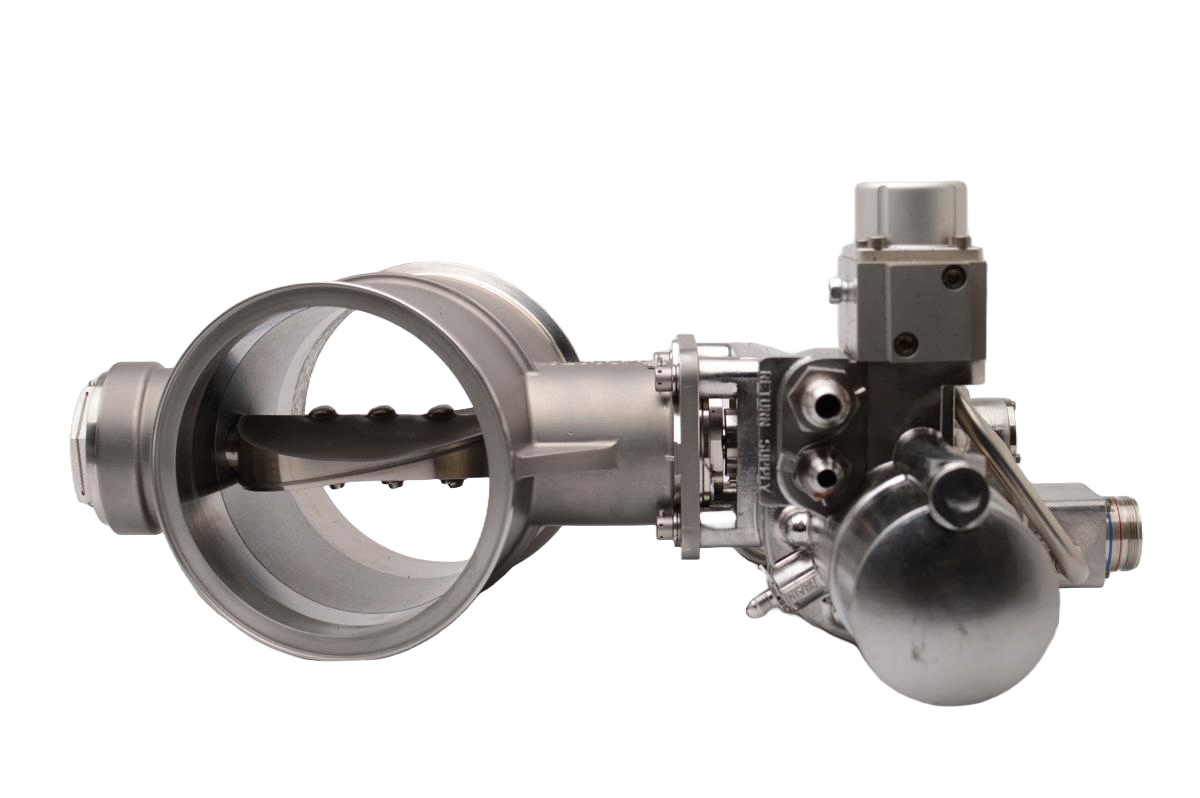

- Effective flow area = 19.1 square inches max.

- Redundant position indicating LVDT.

- Butterfly disk joined to the shaft.

- Fail-safe open.

- Increased thermal isolation of electric components.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The 6″ Butterfly Bleed Air Valve is designed to regulate the flow of compressed bleed air from the compressor section of large gas turbines, such as the LM2500. This valve uses a butterfly-shaped disc permanently attached to a robust shaft, allowing precise control over airflow to reduce pressure and temperature within the turbine system.

With an effective flow area of 19.1 square inches max, this valve accommodates higher volumes of bleed air, making it suitable for turbines with greater airflow requirements. It features a fast response time—less than 320 milliseconds for a full stroke—ensuring timely adjustments to changing operating conditions. The valve’s bearings are engineered for high cycle service, providing durability and reliability even under frequent opening and closing cycles.

The 6″ valve helps protect turbine components by managing thermal loads and maintaining optimal compressor performance, which in turn improves overall turbine efficiency and extends equipment life. It is commonly used in oil and gas applications where maintaining safe, efficient, and reliable turbine operation is critical. This valve also serves as a drop-in replacement in existing turbine systems, requiring no hydraulic or electrical modifications, simplifying installation and reducing downtime.

Engineering Data