Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

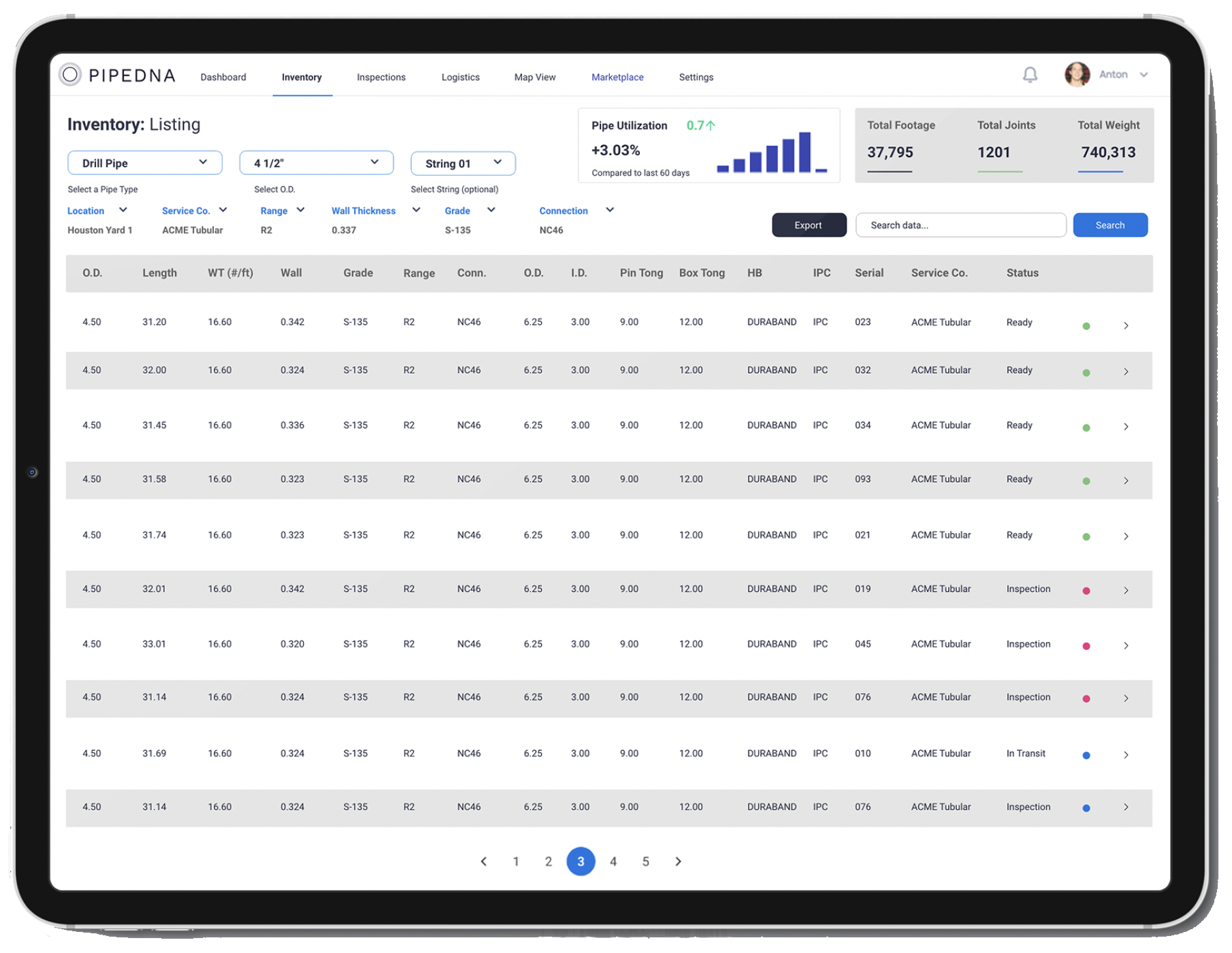

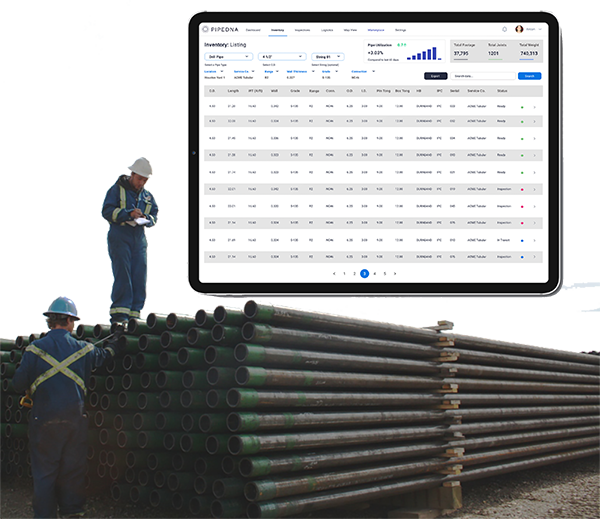

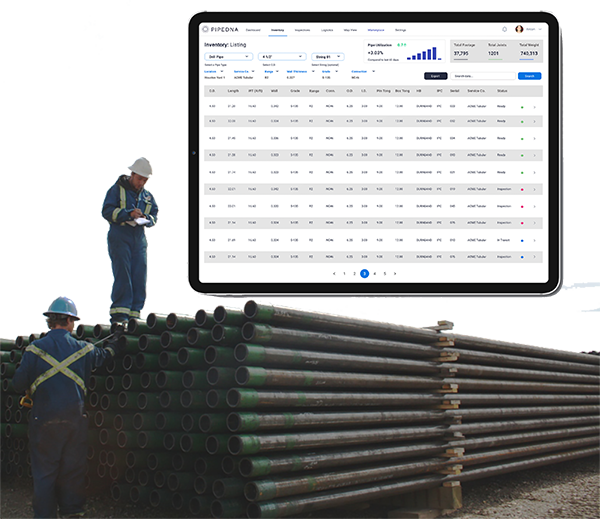

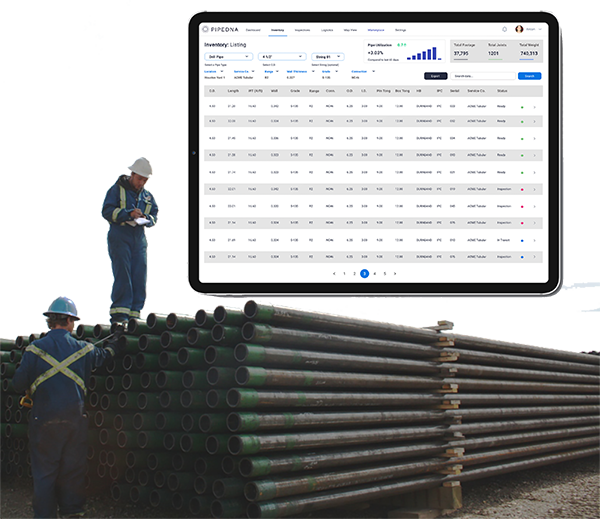

PipeDNA is a cloud-based pipe management solution

Also known as:

OCTG Software, Pipe Management Software, Pipe DatabaseService

Service

New

API

Air Freight

Solutions

Quick pipe identification including pipe documentation

Create and manage tally operations

Manage inspection jobs across multiple sites

Manage logistics operations

Full inventory management and tracking of pipe

Choose

Pipeline Pipe Inventory and Inspection Tracking

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

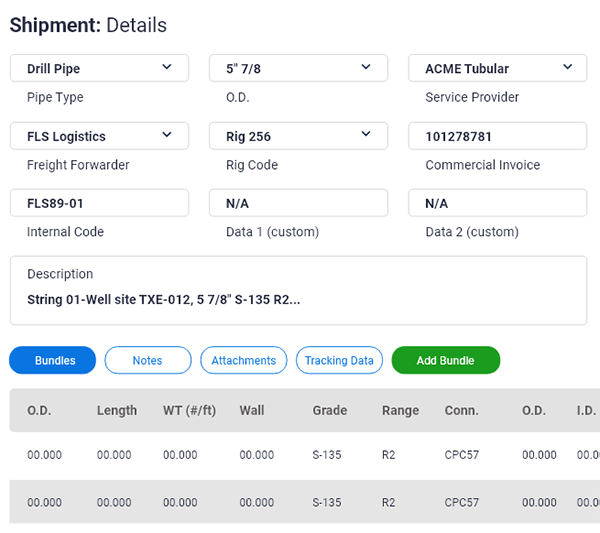

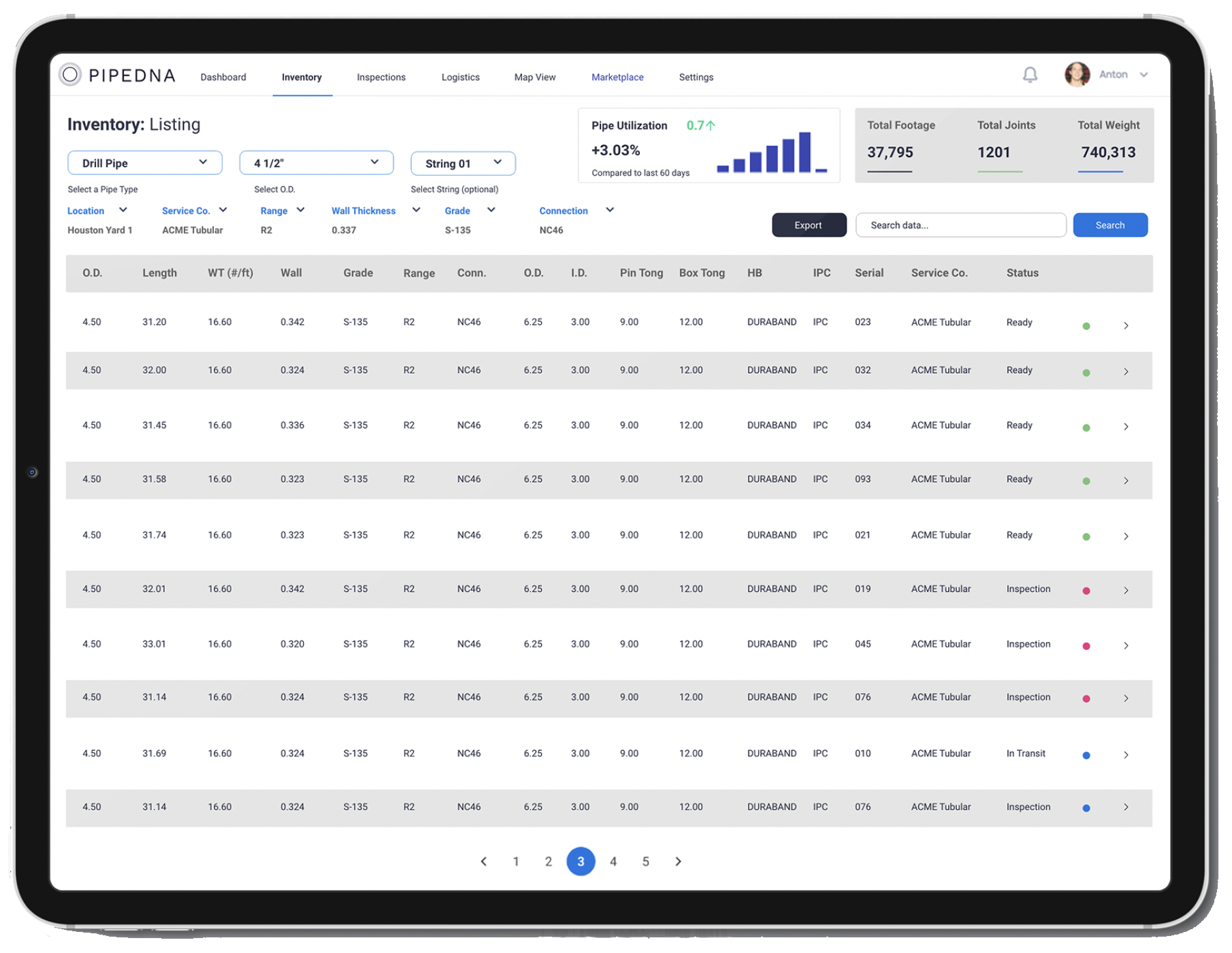

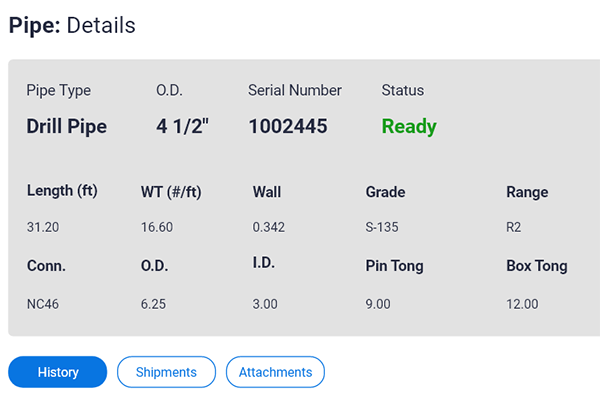

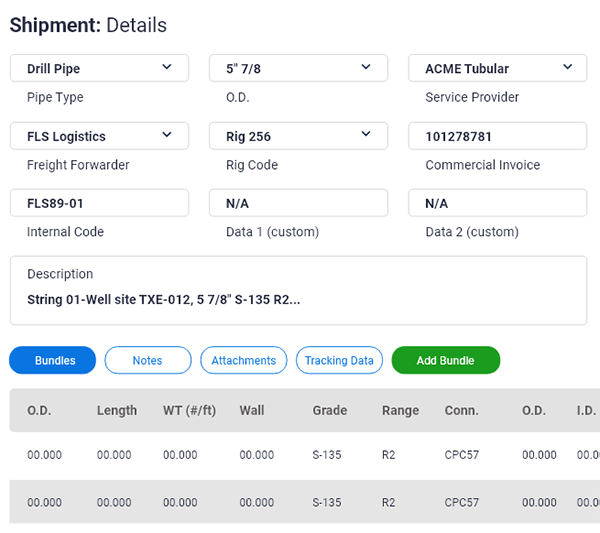

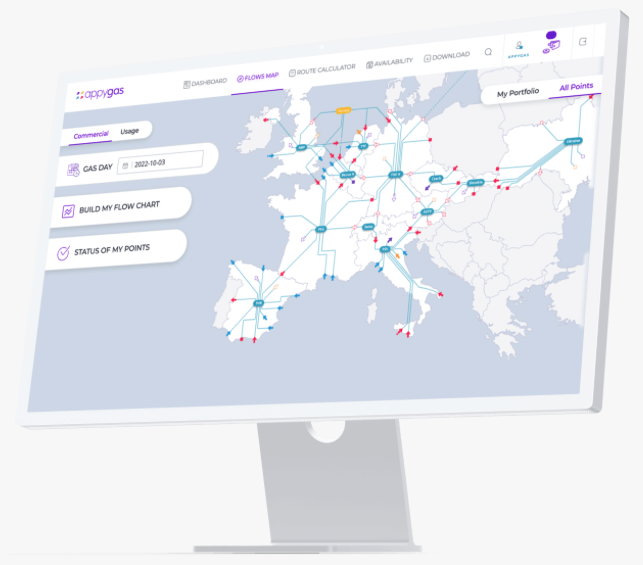

Streamlining Pipeline Pipe Inventory and Inspection Tracking with PipeDNA: Enhancing Efficiency in the Oil and Gas Industry Efficient management of pipeline pipe inventory and inspection tracking is crucial for the smooth operation of the oil and gas industry. Introducing PipeDNA, a state-of-the-art cloud-based platform designed to streamline the management of pipe and tube throughout the entire supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage pipeline pipe inventory, increase visibility, and optimize inspection processes. Comprehensive Inventory and Tracking: PipeDNA provides a comprehensive inventory management and tracking system for pipelines, enabling stakeholders to have a real-time view of their pipeline assets. From monitoring utilization and activity to analyzing trends, the platform equips stakeholders with valuable insights to make informed decisions about their pipeline pipe inventory. With enhanced visibility, stakeholders can optimize inventory levels, minimize downtime, and maximize resource utilization. Efficient Logistics Management: Managing the logistics of pipelines can be complex, but PipeDNA simplifies the process by offering robust logistics management features. Stakeholders can efficiently handle shipments, track the status of pipeline pipe in transit, and streamline documentation processes. Additionally, the platform facilitates pipe bundling, ensuring efficient grouping and transportation of pipeline pipe, leading to cost savings and improved operational efficiency. Streamlined Inspection Management: PipeDNA's inspection management capabilities extend to pipelines, allowing stakeholders to effectively manage inspection jobs across multiple sites. The platform enables seamless coordination, tracking of job statuses, and management of inspection profiles. By centralizing inspection data and streamlining workflows, PipeDNA optimizes the inspection process, ensuring compliance with industry standards and mitigating risks associated with pipeline integrity. Enhanced Identification and Traceability: PipeDNA's identification and traceability features enable quick and reliable identification of pipeline pipe, providing comprehensive details, activity history, and traceability documentation. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, facilitating easy tracking and identification of individual pipelines. By enhancing identification and traceability, PipeDNA strengthens quality control measures, streamlines recalls if necessary, and supports compliance with industry regulations. Seamless Integration of Manufacturing Data: PipeDNA seamlessly integrates manufacturing data into its platform, eliminating the need for manual data entry and reducing the risk of human errors. This integration ensures that pipeline-related data, including manufacturing details, is readily available within the system. By automating the transfer of manufacturing data, PipeDNA enables stakeholders to maintain accurate and reliable records, facilitating efficient pipeline pipe management and data-driven decision-making. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's popular and emerging technologies to optimize pipeline pipe inventory and inspection tracking. The platform supports barcoding and labeling systems, integrating popular barcode standards such as UPC, EAN, and QR codes. Additionally, PipeDNA is RFID ready, enabling stakeholders to seamlessly integrate RFID technologies such as labels and asset tags for efficient tracking and management of pipelines. Furthermore, the platform supports IoT data integrations using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced pipeline pipe management processes. PipeDNA revolutionizes pipeline pipe inventory and inspection tracking in the oil and gas industry, providing stakeholders with a powerful cloud-based solution. By offering comprehensive inventory and tracking capabilities, efficient logistics management, streamlined inspection processes, enhanced identification and traceability, and seamless integration of manufacturing data, PipeDNA empowers stakeholders to maximize efficiency and productivity. Embrace PipeDNA and experience the benefits of improved pipeline pipe management, increased visibility, and optimized operations in the oil and gas supply chain.

Service

Currently in Use

Service

New

ASME

Air Freight

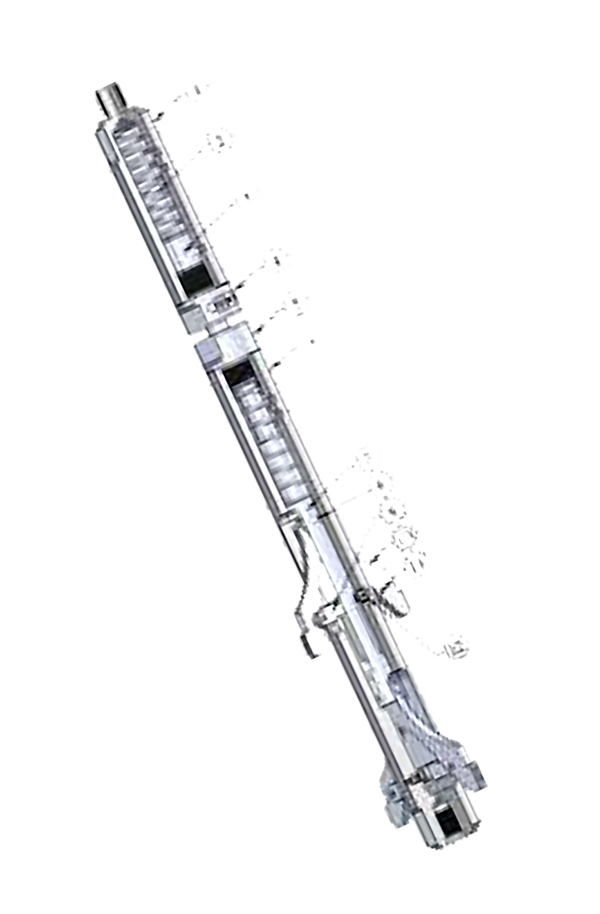

Casing Tracking and Management

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

Streamline Casing Tracking and Management with PipeDNA: Maximizing Efficiency in the Oil and Gas Industry Effective casing tracking and management are essential for ensuring seamless operations in the oil and gas industry. Introducing PipeDNA, a cutting-edge cloud-based platform designed to manage pipe and tube throughout the entire supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively track and manage casing, enhancing visibility, productivity, and operational efficiency. Comprehensive Inventory and Tracking: PipeDNA provides full inventory management and tracking capabilities for casing, enabling stakeholders to have a real-time view of their casing assets. From tracking utilization and activity to identifying trends, the platform equips stakeholders with the tools they need to make informed decisions about their casing inventory. With enhanced visibility, stakeholders can optimize their inventory levels, minimize downtime, and maximize resource utilization. Efficient Logistics Management: Managing casing logistics can be complex, but PipeDNA simplifies the process by offering comprehensive logistics management features. Stakeholders can efficiently handle shipments, track the status of casing in transit, and streamline documentation processes. Additionally, the platform facilitates pipe bundling, ensuring the efficient grouping and transportation of casings, which leads to cost savings and improved operational efficiency. Streamlined Inspection Management: PipeDNA's inspection management capabilities extend to casing, enabling stakeholders to efficiently manage inspection jobs across multiple sites. The platform allows for seamless coordination, tracking of job statuses, and management of inspection profiles. By centralizing inspection data and streamlining workflows, PipeDNA optimizes the inspection process, ensuring compliance with industry standards and mitigating risks associated with faulty casings. Automated Tally Operations: Tallying casing is a critical task that can be time-consuming and prone to errors. PipeDNA simplifies and automates tally operations, allowing stakeholders to create and manage tally jobs within the platform. By automating tally workflows, the platform minimizes manual intervention, reduces errors, and saves valuable time. Stakeholders can confidently rely on accurate tallies, enhancing efficiency and accuracy throughout their casing management processes. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide quick and reliable identification of casing, along with comprehensive details, activity history, and traceability documentation. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, enabling stakeholders to easily track and identify individual casings. By enhancing identification and traceability, PipeDNA strengthens quality control measures, streamlines recalls if necessary, and supports compliance with industry regulations. Seamless Integration of Manufacturing Data: PipeDNA seamlessly integrates manufacturing data into its platform, eliminating the need for manual data entry and reducing the risk of human errors. This integration ensures that casing-related data, including manufacturing details, is readily available within the system. By automating the transfer of manufacturing data, PipeDNA enables stakeholders to maintain accurate and reliable records, facilitating efficient casing management and data-driven decision-making. Leveraging Emerging Technologies: PipeDNA leverages today's emerging technologies to optimize casing tracking and management. The platform supports barcoding and labeling systems, integrating popular barcode standards such as UPC, EAN, and QR codes. Additionally, PipeDNA is RFID ready, enabling stakeholders to integrate RFID technologies such as labels and asset tags for seamless tracking and management of casings. Furthermore, the platform supports IoT data integrations using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced casing management processes. PipeDNA revolutionizes casing tracking and management in the oil and gas industry, providing stakeholders with a powerful cloud-based solution. By offering comprehensive inventory and tracking capabilities, efficient logistics management, streamlined inspection processes, automated tally operations, enhanced identification and traceability, and seamless integration of manufacturing data, PipeDNA empowers stakeholders to maximize efficiency and productivity. Embrace PipeDNA and elevate your casing tracking and management to new levels of effectiveness, enabling seamless operations throughout the oil and gas supply chain.

Service

Currently in Use

Service

New

API

Air Freight

![]() PipeDNA in Houston

PipeDNA in Houston

Pipe Tally Tracking Made Effortless with PipeDNA: Enhancing Accuracy and Efficiency Accurate and efficient pipe tally tracking is crucial in the oil and gas industry to ensure the smooth flow of operations and maintain optimal inventory levels. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage their pipe tally operations, automate workflows, and increase visibility, ultimately improving productivity and reducing costs. Streamline Pipe Tally Operations: PipeDNA offers a comprehensive set of tools to simplify the creation and management of pipe tally operations. With intuitive functionalities, users can effortlessly create and configure tally jobs, define parameters, and automate the entire tallying process. By eliminating the need for manual calculations and paperwork, PipeDNA streamlines pipe tally operations, saving time and reducing the potential for errors. Automated Workflows for Increased Efficiency: The automation capabilities of PipeDNA revolutionize pipe tally tracking, enabling stakeholders to implement standardized and efficient workflows. Once the tally operations are set up, PipeDNA automates the process by capturing real-time data and performing calculations, ensuring accurate and up-to-date tally results. By eliminating manual data entry and reducing human errors, PipeDNA enhances the overall efficiency of pipe tallying processes. Real-Time Visibility and Reporting: PipeDNA's inventory management and tracking feature provide real-time visibility into pipe utilization, activity, and trends. With a centralized dashboard, stakeholders can access comprehensive reports and analytics, allowing them to make data-driven decisions regarding inventory optimization, resource allocation, and operational planning. The ability to track pipe movements and monitor tally results in real-time empowers stakeholders with valuable insights, fostering informed decision-making. Seamless Integration for Enhanced Traceability: Identification and traceability are essential aspects of pipe management. PipeDNA excels in providing quick and accurate pipe identification through its integration capabilities. By seamlessly integrating with popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables users to easily identify and track pipe details, activity history, and traceability documentation. This integration ensures that stakeholders can swiftly locate and trace specific pipes, reducing downtime and improving operational efficiency. Designed for the Oil and Gas Industry: PipeDNA was meticulously crafted by drilling engineers and technology innovators to cater to the unique needs of stakeholders across drilling, manufacturing, and oilfield services. Whether it's drilling contractors, oilfield rental companies, oilfield and inspection services, steel pipe manufacturers, or pipe distribution and storage providers, PipeDNA offers tailored solutions to enhance their pipe tally tracking processes. Leveraging Emerging Technologies: At its core, PipeDNA leverages the latest advancements in technology to streamline workflows and digitize pipe management processes. The platform is RFID ready, offering seamless integration with RFID technologies such as labels and asset tags. Additionally, PipeDNA supports IoT data integration using the MQTT standard, enabling fast and efficient integration of sensor data. These emerging technologies empower stakeholders to harness the power of automation and data-driven insights for improved pipe tally tracking. PipeDNA revolutionizes pipe tally tracking in the oil and gas industry by providing a smart cloud-based platform that enhances accuracy, efficiency, and visibility. With its powerful features, seamless integration capabilities, and commitment to leveraging emerging technologies, PipeDNA empowers stakeholders to proactively manage their pipe tally operations, automate workflows, and make informed decisions based on real-time data. Streamline your pipe tally tracking processes with PipeDNA and elevate your operational efficiency to new heights.

Service

Currently in Use

Service

New

API

Air Freight

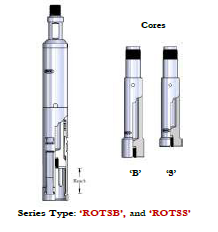

Tubular Manufacturing Traceability

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

Enhancing Tubular Manufacturing Traceability with PipeDNA: Ensuring Quality and Compliance In the oil and gas industry, maintaining traceability throughout the tubular manufacturing process is crucial for ensuring quality, compliance, and operational efficiency. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage tubular manufacturing traceability, increase visibility, and optimize their operations for enhanced quality control. Comprehensive Inventory Management and Tracking: PipeDNA offers comprehensive inventory management and tracking capabilities for tubular products, enabling stakeholders to have full visibility into their manufacturing processes. From raw materials to finished products, PipeDNA allows for seamless tracking of each component, ensuring accurate inventory control, reducing waste, and optimizing production planning. Gain insights into utilization, activity, and trends, empowering stakeholders to make data-driven decisions and streamline their manufacturing operations. Streamlined Logistics Management: PipeDNA simplifies logistics management by providing stakeholders with a centralized platform to manage shipments, track status, and document crucial information. Whether it's inbound or outbound logistics, PipeDNA ensures seamless coordination and real-time visibility into the movement of tubular products. The platform also facilitates pipe bundling, allowing stakeholders to optimize transportation and storage, reducing costs and improving overall efficiency. Efficient Inspection Management: With PipeDNA's inspection management feature, stakeholders can effectively manage inspection jobs throughout the tubular manufacturing process. From initial inspections of raw materials to final product inspections, PipeDNA enables tracking and monitoring of job status across multiple sites. By streamlining inspection profiles and documentation, stakeholders can ensure compliance with quality standards, reduce errors, and maintain consistent product quality. Automated Tally Operations: PipeDNA simplifies and automates the tallying process during tubular manufacturing. Stakeholders can create and manage tally operations within the platform, eliminating manual calculations and reducing the risk of errors. By automating pipe tally jobs and workflows, PipeDNA saves time, improves accuracy, and enhances overall manufacturing efficiency. Accurate tally operations enable stakeholders to maintain reliable records and ensure traceability throughout the production cycle. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide stakeholders with quick and accurate pipe identification, detailed pipe information, activity history, and traceability documentation. By integrating popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables seamless identification and tracking of each tubular product. This enhanced traceability minimizes the risk of errors, supports efficient recalls if necessary, and ensures compliance with industry regulations. Designed for the Oil and Gas Industry: PipeDNA was designed specifically for stakeholders across drilling, manufacturing, and oilfield services, catering to their unique needs in tubular manufacturing traceability. Whether you are a drilling contractor, oilfield rental company, oilfield and inspection service provider, steel pipe manufacturer, or pipe distribution and storage provider, PipeDNA offers tailored solutions to streamline your tubular manufacturing processes and drive quality and compliance. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's emerging technologies to optimize tubular manufacturing traceability. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, allowing for efficient barcoding and labeling. Furthermore, PipeDNA is RFID ready, supporting the integration of RFID technologies for accurate asset tracking and improved traceability. The platform also enables IoT data integration using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced decision-making during the manufacturing process. PipeDNA revolutionizes tubular manufacturing traceability in the oil and gas industry, providing a smart cloud-based platform that enhances quality control, compliance, and visibility. With its comprehensive inventory management, streamlined logistics operations, efficient inspection management, automated tally operations, and enhanced identification and traceability features, PipeDNA empowers stakeholders to optimize their tubular manufacturing processes, minimize errors, and ensure compliance with industry standards. Leverage the power of PipeDNA and take your tubular manufacturing traceability to new heights of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

![]() PipeDNA in Houston

PipeDNA in Houston

Streamlining OCTG Tubular Goods Management with PipeDNA: Boosting Efficiency and Reliability Efficient management of OCTG (Oil Country Tubular Goods) is critical in the oil and gas industry to ensure the success of drilling and production operations. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage their OCTG tubular goods, increase visibility, and optimize their operations for enhanced efficiency and reliability. Comprehensive Inventory Management and Tracking: PipeDNA offers a comprehensive inventory management and tracking system specifically tailored for OCTG tubular goods. Gain full visibility into your OCTG inventory, including utilization, activity, and trends. By monitoring the status and location of each OCTG pipe, stakeholders can proactively plan for upcoming drilling projects, streamline logistics, and optimize inventory levels. PipeDNA enables accurate tracking, reducing the risk of stockouts, minimizing downtime, and maximizing operational efficiency. Efficient Logistics Management: With PipeDNA, stakeholders can efficiently manage all aspects of logistics operations related to OCTG tubular goods. From shipments to status tracking and documentation, PipeDNA simplifies the entire process, ensuring seamless coordination across multiple locations and parties involved. Furthermore, the platform facilitates pipe bundling, enabling stakeholders to optimize transportation and storage, minimizing costs and improving overall efficiency. Streamlined Inspection Management: PipeDNA's inspection management feature provides a centralized platform to manage inspection jobs for OCTG tubular goods across multiple sites. With real-time tracking and status updates, stakeholders can monitor the progress of inspection jobs, ensuring timely completion and adherence to quality standards. Additionally, the platform enables the management of inspection profiles, allowing for efficient scheduling, tracking, and reporting of inspection activities. Automated Tally Operations: Pipe tallying is a crucial process in OCTG tubular goods management, and PipeDNA simplifies this operation with automated tally operations. Stakeholders can create and manage tally operations within the platform, streamlining the process and eliminating manual calculations. By automating pipe tally jobs and workflows, PipeDNA saves time, reduces errors, and ensures accurate and up-to-date tally results, enhancing overall operational efficiency. Enhanced Identification and Traceability: PipeDNA offers quick and accurate identification of OCTG tubular goods, providing stakeholders with essential pipe details, activity history, and traceability documentation. With seamless integration of popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables easy identification and tracking of each pipe, ensuring precise inventory control and reducing the risk of misplaced or misused OCTG tubular goods. This enhanced traceability minimizes downtime and improves resource allocation. Designed for the Oil and Gas Industry: PipeDNA was specifically designed for stakeholders across drilling, manufacturing, and oilfield services, catering to their unique needs in OCTG tubular goods management. Whether you are a drilling contractor, oilfield rental company, oilfield and inspection service provider, steel pipe manufacturer, or pipe distribution and storage provider, PipeDNA offers tailored solutions to streamline your OCTG operations and drive efficiency. Leveraging Emerging Technologies: At its core, PipeDNA harnesses the power of today's emerging technologies to optimize OCTG tubular goods management processes. The platform seamlessly integrates with popular barcode standards, such as UPC, EAN, and QR codes, enabling efficient barcoding and labeling. Moreover, PipeDNA is RFID ready, supporting the integration of RFID technologies for accurate asset tracking. The platform also facilitates IoT data integration using the MQTT standard, enabling fast and reliable sensor data integration for enhanced decision-making. PipeDNA revolutionizes OCTG tubular goods management in the oil and gas industry, providing a smart cloud-based platform that enhances efficiency, reliability, and visibility. With its comprehensive inventory management, streamlined logistics operations, automated tallying, and robust identification and traceability features, PipeDNA empowers stakeholders to optimize their OCTG operations and make informed decisions based on real-time data. Leverage the power of PipeDNA and take your OCTG tubular goods management to new heights of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

Tubular Manufacturing Traceability

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

Enhancing Tubular Manufacturing Traceability with PipeDNA: Ensuring Quality and Compliance In the oil and gas industry, maintaining traceability throughout the tubular manufacturing process is crucial for ensuring quality, compliance, and operational efficiency. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage tubular manufacturing traceability, increase visibility, and optimize their operations for enhanced quality control. Comprehensive Inventory Management and Tracking: PipeDNA offers comprehensive inventory management and tracking capabilities for tubular products, enabling stakeholders to have full visibility into their manufacturing processes. From raw materials to finished products, PipeDNA allows for seamless tracking of each component, ensuring accurate inventory control, reducing waste, and optimizing production planning. Gain insights into utilization, activity, and trends, empowering stakeholders to make data-driven decisions and streamline their manufacturing operations. Streamlined Logistics Management: PipeDNA simplifies logistics management by providing stakeholders with a centralized platform to manage shipments, track status, and document crucial information. Whether it's inbound or outbound logistics, PipeDNA ensures seamless coordination and real-time visibility into the movement of tubular products. The platform also facilitates pipe bundling, allowing stakeholders to optimize transportation and storage, reducing costs and improving overall efficiency. Efficient Inspection Management: With PipeDNA's inspection management feature, stakeholders can effectively manage inspection jobs throughout the tubular manufacturing process. From initial inspections of raw materials to final product inspections, PipeDNA enables tracking and monitoring of job status across multiple sites. By streamlining inspection profiles and documentation, stakeholders can ensure compliance with quality standards, reduce errors, and maintain consistent product quality. Automated Tally Operations: PipeDNA simplifies and automates the tallying process during tubular manufacturing. Stakeholders can create and manage tally operations within the platform, eliminating manual calculations and reducing the risk of errors. By automating pipe tally jobs and workflows, PipeDNA saves time, improves accuracy, and enhances overall manufacturing efficiency. Accurate tally operations enable stakeholders to maintain reliable records and ensure traceability throughout the production cycle. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide stakeholders with quick and accurate pipe identification, detailed pipe information, activity history, and traceability documentation. By integrating popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables seamless identification and tracking of each tubular product. This enhanced traceability minimizes the risk of errors, supports efficient recalls if necessary, and ensures compliance with industry regulations. Designed for the Oil and Gas Industry: PipeDNA was designed specifically for stakeholders across drilling, manufacturing, and oilfield services, catering to their unique needs in tubular manufacturing traceability. Whether you are a drilling contractor, oilfield rental company, oilfield and inspection service provider, steel pipe manufacturer, or pipe distribution and storage provider, PipeDNA offers tailored solutions to streamline your tubular manufacturing processes and drive quality and compliance. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's emerging technologies to optimize tubular manufacturing traceability. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, allowing for efficient barcoding and labeling. Furthermore, PipeDNA is RFID ready, supporting the integration of RFID technologies for accurate asset tracking and improved traceability. The platform also enables IoT data integration using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced decision-making during the manufacturing process. PipeDNA revolutionizes tubular manufacturing traceability in the oil and gas industry, providing a smart cloud-based platform that enhances quality control, compliance, and visibility. With its comprehensive inventory management, streamlined logistics operations, efficient inspection management, automated tally operations, and enhanced identification and traceability features, PipeDNA empowers stakeholders to optimize their tubular manufacturing processes, minimize errors, and ensure compliance with industry standards. Leverage the power of PipeDNA and take your tubular manufacturing traceability to new heights of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

![]() PipeDNA in Houston

PipeDNA in Houston

Pipe Tally Tracking Made Effortless with PipeDNA: Enhancing Accuracy and Efficiency Accurate and efficient pipe tally tracking is crucial in the oil and gas industry to ensure the smooth flow of operations and maintain optimal inventory levels. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage their pipe tally operations, automate workflows, and increase visibility, ultimately improving productivity and reducing costs. Streamline Pipe Tally Operations: PipeDNA offers a comprehensive set of tools to simplify the creation and management of pipe tally operations. With intuitive functionalities, users can effortlessly create and configure tally jobs, define parameters, and automate the entire tallying process. By eliminating the need for manual calculations and paperwork, PipeDNA streamlines pipe tally operations, saving time and reducing the potential for errors. Automated Workflows for Increased Efficiency: The automation capabilities of PipeDNA revolutionize pipe tally tracking, enabling stakeholders to implement standardized and efficient workflows. Once the tally operations are set up, PipeDNA automates the process by capturing real-time data and performing calculations, ensuring accurate and up-to-date tally results. By eliminating manual data entry and reducing human errors, PipeDNA enhances the overall efficiency of pipe tallying processes. Real-Time Visibility and Reporting: PipeDNA's inventory management and tracking feature provide real-time visibility into pipe utilization, activity, and trends. With a centralized dashboard, stakeholders can access comprehensive reports and analytics, allowing them to make data-driven decisions regarding inventory optimization, resource allocation, and operational planning. The ability to track pipe movements and monitor tally results in real-time empowers stakeholders with valuable insights, fostering informed decision-making. Seamless Integration for Enhanced Traceability: Identification and traceability are essential aspects of pipe management. PipeDNA excels in providing quick and accurate pipe identification through its integration capabilities. By seamlessly integrating with popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables users to easily identify and track pipe details, activity history, and traceability documentation. This integration ensures that stakeholders can swiftly locate and trace specific pipes, reducing downtime and improving operational efficiency. Designed for the Oil and Gas Industry: PipeDNA was meticulously crafted by drilling engineers and technology innovators to cater to the unique needs of stakeholders across drilling, manufacturing, and oilfield services. Whether it's drilling contractors, oilfield rental companies, oilfield and inspection services, steel pipe manufacturers, or pipe distribution and storage providers, PipeDNA offers tailored solutions to enhance their pipe tally tracking processes. Leveraging Emerging Technologies: At its core, PipeDNA leverages the latest advancements in technology to streamline workflows and digitize pipe management processes. The platform is RFID ready, offering seamless integration with RFID technologies such as labels and asset tags. Additionally, PipeDNA supports IoT data integration using the MQTT standard, enabling fast and efficient integration of sensor data. These emerging technologies empower stakeholders to harness the power of automation and data-driven insights for improved pipe tally tracking. PipeDNA revolutionizes pipe tally tracking in the oil and gas industry by providing a smart cloud-based platform that enhances accuracy, efficiency, and visibility. With its powerful features, seamless integration capabilities, and commitment to leveraging emerging technologies, PipeDNA empowers stakeholders to proactively manage their pipe tally operations, automate workflows, and make informed decisions based on real-time data. Streamline your pipe tally tracking processes with PipeDNA and elevate your operational efficiency to new heights.

Service

Currently in Use

Service

New

API

Air Freight

![]() PipeDNA in Houston

PipeDNA in Houston

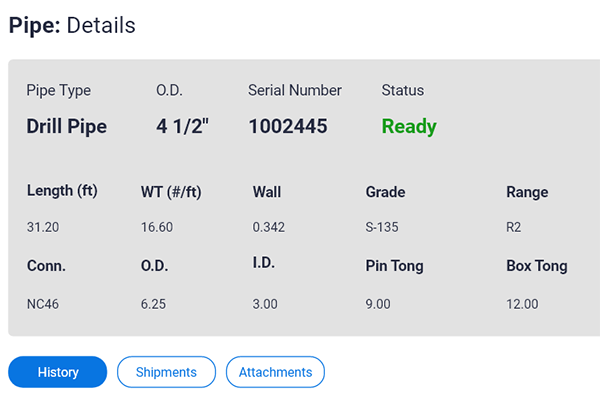

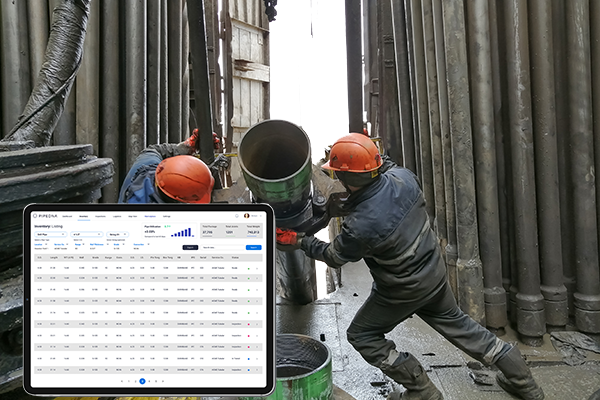

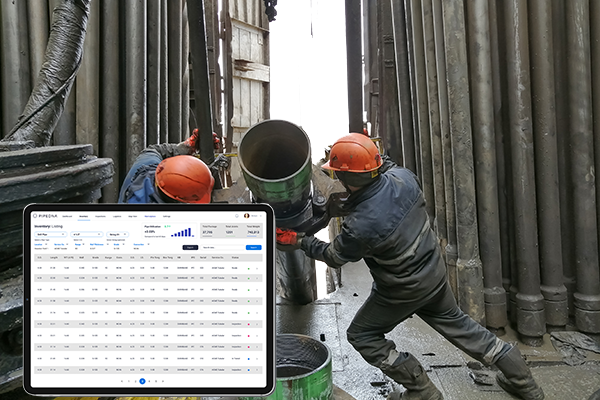

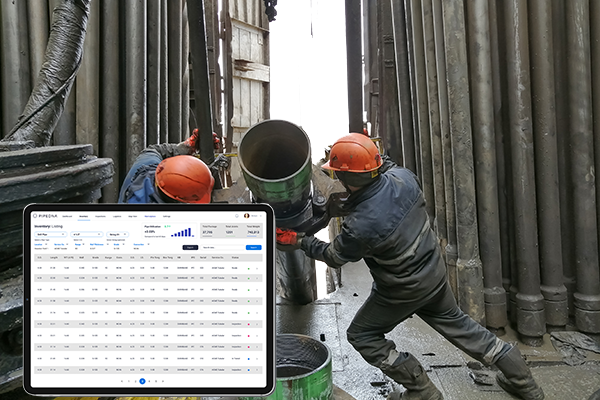

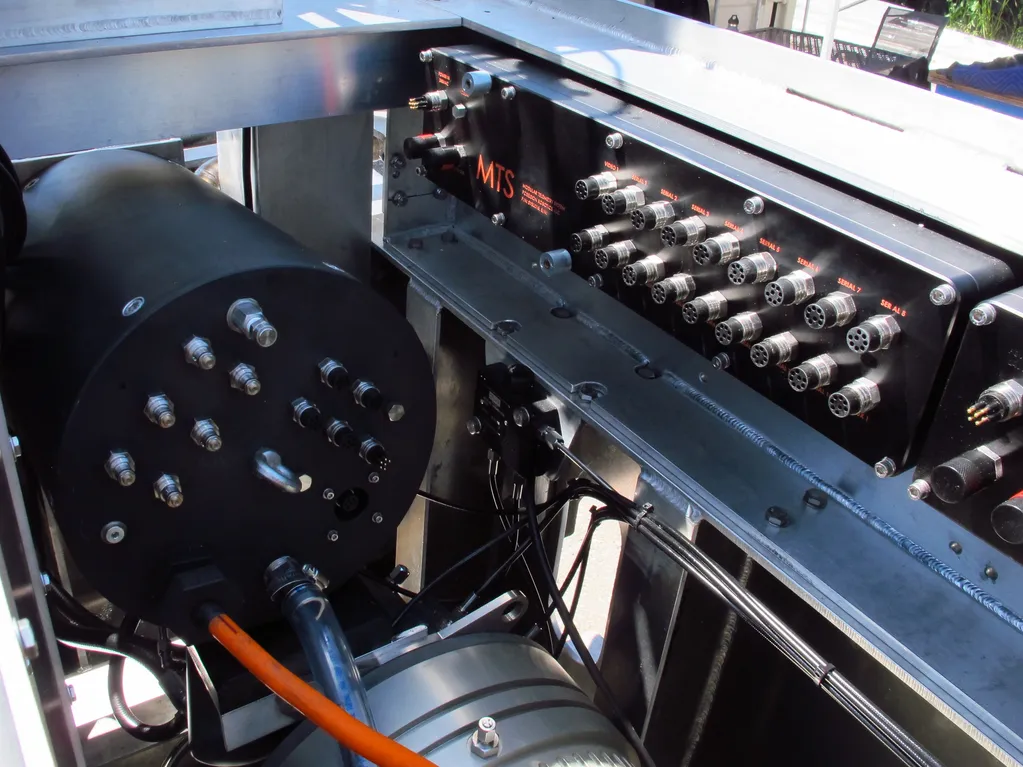

Streamline Drill Pipe Management with PipeDNA: Enhancing Efficiency and Visibility on the Drilling Rig Efficient management of drill pipe is a critical factor in ensuring smooth drilling operations in the oil and gas industry. Introducing PipeDNA, a smart new platform designed to revolutionize the way drill pipe is managed on the drilling rig. With its cloud-based solution and powerful features, PipeDNA empowers drilling contractors, oilfield rental companies, and oilfield services providers to proactively manage their drill pipe inventory, increase visibility, and optimize their drilling operations. Full Inventory Management and Tracking: PipeDNA offers a comprehensive set of features that enable drill pipe stakeholders to gain complete control over their inventory. With its inventory management and tracking capabilities, PipeDNA provides real-time information on drill pipe utilization, activity, and trends. This invaluable insight allows drilling contractors to make informed decisions regarding drill pipe allocation, maintenance schedules, and resource optimization. Efficient Logistics Management: Managing logistics operations on the drilling rig can be complex and time-consuming. PipeDNA simplifies this process by offering robust logistics management functionalities. Users can efficiently handle shipments, track the status of drill pipe deliveries, manage documentation, and even bundle pipes for streamlined transportation. With PipeDNA, logistics become a well-coordinated and seamless aspect of drill pipe management, saving time and resources. Streamlined Inspection Management: Inspection is crucial for ensuring the integrity and safety of drill pipe. PipeDNA's inspection management feature enables users to efficiently manage inspection jobs across multiple sites, track job statuses, and maintain inspection profiles. This capability ensures that inspections are conducted in a timely manner, minimizing downtime and optimizing drilling operations. Automated Tally Operations: Pipe tallying is a time-consuming task prone to human errors when done manually. PipeDNA simplifies tally operations by providing users with the ability to create and manage tally operations. Automated workflows streamline the tallying process, reducing errors and saving valuable time. By automating tally operations, PipeDNA allows drill pipe stakeholders to focus on more critical aspects of their drilling operations. Enhanced Identification and Traceability: Quick and accurate identification of drill pipe assets is crucial for efficient drilling operations. PipeDNA offers a robust identification and traceability system that provides users with comprehensive drill pipe details, activity history, and traceability documentation. With PipeDNA, drill pipe stakeholders can quickly locate and track specific pipes, ensuring smooth operations and minimizing the risk of errors. Support for Various Drill Pipe Types: PipeDNA's innovative technology is designed to accommodate various types of drill pipe, providing flexibility and adaptability. The platform supports the management of new and premium drill pipe, conventional and spiral HWDP (Heavy Weight Drill Pipe), landing strings, and drilling risers. Whether it's EUE or NUE tubing, workover strings, slick or spiral drill collars, or API 6A flanges, PipeDNA can efficiently manage a wide range of drill pipe and tube types, catering to the diverse needs of the drilling industry. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's popular and emerging technologies to streamline workflows and digitize drill pipe management processes. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, facilitating seamless identification and tracking. PipeDNA is also RFID-ready, providing integration support for RFID technologies, including labels and asset tags. Furthermore, the platform supports IoT data integration using the MQTT standard, allowing fast and efficient integration of sensor data. PipeDNA is transforming drill pipe management on the drilling rig, offering a cloud-based platform that enhances efficiency, increases visibility, and optimizes drilling operations. With its powerful features, seamless integrations, and innovative technology, PipeDNA empowers drilling contractors, rental companies, and oilfield services providers to proactively manage their drill pipe inventory, reduce costs, and improve overall performance. Streamline your drill pipe management processes with PipeDNA and elevate your drilling operations to new heights of productivity and success.

Service

Currently in Use

Service

New

API

Air Freight

Casing Tracking and Management

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

Streamline Casing Tracking and Management with PipeDNA: Maximizing Efficiency in the Oil and Gas Industry Effective casing tracking and management are essential for ensuring seamless operations in the oil and gas industry. Introducing PipeDNA, a cutting-edge cloud-based platform designed to manage pipe and tube throughout the entire supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively track and manage casing, enhancing visibility, productivity, and operational efficiency. Comprehensive Inventory and Tracking: PipeDNA provides full inventory management and tracking capabilities for casing, enabling stakeholders to have a real-time view of their casing assets. From tracking utilization and activity to identifying trends, the platform equips stakeholders with the tools they need to make informed decisions about their casing inventory. With enhanced visibility, stakeholders can optimize their inventory levels, minimize downtime, and maximize resource utilization. Efficient Logistics Management: Managing casing logistics can be complex, but PipeDNA simplifies the process by offering comprehensive logistics management features. Stakeholders can efficiently handle shipments, track the status of casing in transit, and streamline documentation processes. Additionally, the platform facilitates pipe bundling, ensuring the efficient grouping and transportation of casings, which leads to cost savings and improved operational efficiency. Streamlined Inspection Management: PipeDNA's inspection management capabilities extend to casing, enabling stakeholders to efficiently manage inspection jobs across multiple sites. The platform allows for seamless coordination, tracking of job statuses, and management of inspection profiles. By centralizing inspection data and streamlining workflows, PipeDNA optimizes the inspection process, ensuring compliance with industry standards and mitigating risks associated with faulty casings. Automated Tally Operations: Tallying casing is a critical task that can be time-consuming and prone to errors. PipeDNA simplifies and automates tally operations, allowing stakeholders to create and manage tally jobs within the platform. By automating tally workflows, the platform minimizes manual intervention, reduces errors, and saves valuable time. Stakeholders can confidently rely on accurate tallies, enhancing efficiency and accuracy throughout their casing management processes. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide quick and reliable identification of casing, along with comprehensive details, activity history, and traceability documentation. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, enabling stakeholders to easily track and identify individual casings. By enhancing identification and traceability, PipeDNA strengthens quality control measures, streamlines recalls if necessary, and supports compliance with industry regulations. Seamless Integration of Manufacturing Data: PipeDNA seamlessly integrates manufacturing data into its platform, eliminating the need for manual data entry and reducing the risk of human errors. This integration ensures that casing-related data, including manufacturing details, is readily available within the system. By automating the transfer of manufacturing data, PipeDNA enables stakeholders to maintain accurate and reliable records, facilitating efficient casing management and data-driven decision-making. Leveraging Emerging Technologies: PipeDNA leverages today's emerging technologies to optimize casing tracking and management. The platform supports barcoding and labeling systems, integrating popular barcode standards such as UPC, EAN, and QR codes. Additionally, PipeDNA is RFID ready, enabling stakeholders to integrate RFID technologies such as labels and asset tags for seamless tracking and management of casings. Furthermore, the platform supports IoT data integrations using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced casing management processes. PipeDNA revolutionizes casing tracking and management in the oil and gas industry, providing stakeholders with a powerful cloud-based solution. By offering comprehensive inventory and tracking capabilities, efficient logistics management, streamlined inspection processes, automated tally operations, enhanced identification and traceability, and seamless integration of manufacturing data, PipeDNA empowers stakeholders to maximize efficiency and productivity. Embrace PipeDNA and elevate your casing tracking and management to new levels of effectiveness, enabling seamless operations throughout the oil and gas supply chain.

Service

Currently in Use

Service

New

API

Air Freight

Pipeline Pipe Inventory and Inspection Tracking

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

Streamlining Pipeline Pipe Inventory and Inspection Tracking with PipeDNA: Enhancing Efficiency in the Oil and Gas Industry Efficient management of pipeline pipe inventory and inspection tracking is crucial for the smooth operation of the oil and gas industry. Introducing PipeDNA, a state-of-the-art cloud-based platform designed to streamline the management of pipe and tube throughout the entire supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage pipeline pipe inventory, increase visibility, and optimize inspection processes. Comprehensive Inventory and Tracking: PipeDNA provides a comprehensive inventory management and tracking system for pipelines, enabling stakeholders to have a real-time view of their pipeline assets. From monitoring utilization and activity to analyzing trends, the platform equips stakeholders with valuable insights to make informed decisions about their pipeline pipe inventory. With enhanced visibility, stakeholders can optimize inventory levels, minimize downtime, and maximize resource utilization. Efficient Logistics Management: Managing the logistics of pipelines can be complex, but PipeDNA simplifies the process by offering robust logistics management features. Stakeholders can efficiently handle shipments, track the status of pipeline pipe in transit, and streamline documentation processes. Additionally, the platform facilitates pipe bundling, ensuring efficient grouping and transportation of pipeline pipe, leading to cost savings and improved operational efficiency. Streamlined Inspection Management: PipeDNA's inspection management capabilities extend to pipelines, allowing stakeholders to effectively manage inspection jobs across multiple sites. The platform enables seamless coordination, tracking of job statuses, and management of inspection profiles. By centralizing inspection data and streamlining workflows, PipeDNA optimizes the inspection process, ensuring compliance with industry standards and mitigating risks associated with pipeline integrity. Enhanced Identification and Traceability: PipeDNA's identification and traceability features enable quick and reliable identification of pipeline pipe, providing comprehensive details, activity history, and traceability documentation. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, facilitating easy tracking and identification of individual pipelines. By enhancing identification and traceability, PipeDNA strengthens quality control measures, streamlines recalls if necessary, and supports compliance with industry regulations. Seamless Integration of Manufacturing Data: PipeDNA seamlessly integrates manufacturing data into its platform, eliminating the need for manual data entry and reducing the risk of human errors. This integration ensures that pipeline-related data, including manufacturing details, is readily available within the system. By automating the transfer of manufacturing data, PipeDNA enables stakeholders to maintain accurate and reliable records, facilitating efficient pipeline pipe management and data-driven decision-making. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's popular and emerging technologies to optimize pipeline pipe inventory and inspection tracking. The platform supports barcoding and labeling systems, integrating popular barcode standards such as UPC, EAN, and QR codes. Additionally, PipeDNA is RFID ready, enabling stakeholders to seamlessly integrate RFID technologies such as labels and asset tags for efficient tracking and management of pipelines. Furthermore, the platform supports IoT data integrations using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced pipeline pipe management processes. PipeDNA revolutionizes pipeline pipe inventory and inspection tracking in the oil and gas industry, providing stakeholders with a powerful cloud-based solution. By offering comprehensive inventory and tracking capabilities, efficient logistics management, streamlined inspection processes, enhanced identification and traceability, and seamless integration of manufacturing data, PipeDNA empowers stakeholders to maximize efficiency and productivity. Embrace PipeDNA and experience the benefits of improved pipeline pipe management, increased visibility, and optimized operations in the oil and gas supply chain.

Service

Currently in Use

Service

New

ASME

Air Freight

![]() PipeDNA in Houston

PipeDNA in Houston

Pipe Tally Tracking Made Effortless with PipeDNA: Enhancing Accuracy and Efficiency Accurate and efficient pipe tally tracking is crucial in the oil and gas industry to ensure the smooth flow of operations and maintain optimal inventory levels. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage their pipe tally operations, automate workflows, and increase visibility, ultimately improving productivity and reducing costs. Streamline Pipe Tally Operations: PipeDNA offers a comprehensive set of tools to simplify the creation and management of pipe tally operations. With intuitive functionalities, users can effortlessly create and configure tally jobs, define parameters, and automate the entire tallying process. By eliminating the need for manual calculations and paperwork, PipeDNA streamlines pipe tally operations, saving time and reducing the potential for errors. Automated Workflows for Increased Efficiency: The automation capabilities of PipeDNA revolutionize pipe tally tracking, enabling stakeholders to implement standardized and efficient workflows. Once the tally operations are set up, PipeDNA automates the process by capturing real-time data and performing calculations, ensuring accurate and up-to-date tally results. By eliminating manual data entry and reducing human errors, PipeDNA enhances the overall efficiency of pipe tallying processes. Real-Time Visibility and Reporting: PipeDNA's inventory management and tracking feature provide real-time visibility into pipe utilization, activity, and trends. With a centralized dashboard, stakeholders can access comprehensive reports and analytics, allowing them to make data-driven decisions regarding inventory optimization, resource allocation, and operational planning. The ability to track pipe movements and monitor tally results in real-time empowers stakeholders with valuable insights, fostering informed decision-making. Seamless Integration for Enhanced Traceability: Identification and traceability are essential aspects of pipe management. PipeDNA excels in providing quick and accurate pipe identification through its integration capabilities. By seamlessly integrating with popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables users to easily identify and track pipe details, activity history, and traceability documentation. This integration ensures that stakeholders can swiftly locate and trace specific pipes, reducing downtime and improving operational efficiency. Designed for the Oil and Gas Industry: PipeDNA was meticulously crafted by drilling engineers and technology innovators to cater to the unique needs of stakeholders across drilling, manufacturing, and oilfield services. Whether it's drilling contractors, oilfield rental companies, oilfield and inspection services, steel pipe manufacturers, or pipe distribution and storage providers, PipeDNA offers tailored solutions to enhance their pipe tally tracking processes. Leveraging Emerging Technologies: At its core, PipeDNA leverages the latest advancements in technology to streamline workflows and digitize pipe management processes. The platform is RFID ready, offering seamless integration with RFID technologies such as labels and asset tags. Additionally, PipeDNA supports IoT data integration using the MQTT standard, enabling fast and efficient integration of sensor data. These emerging technologies empower stakeholders to harness the power of automation and data-driven insights for improved pipe tally tracking. PipeDNA revolutionizes pipe tally tracking in the oil and gas industry by providing a smart cloud-based platform that enhances accuracy, efficiency, and visibility. With its powerful features, seamless integration capabilities, and commitment to leveraging emerging technologies, PipeDNA empowers stakeholders to proactively manage their pipe tally operations, automate workflows, and make informed decisions based on real-time data. Streamline your pipe tally tracking processes with PipeDNA and elevate your operational efficiency to new heights.

Service

Currently in Use

Service

New

API

Air Freight

Pipeline Pipe Inventory and Inspection Tracking

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

Streamlining Pipeline Pipe Inventory and Inspection Tracking with PipeDNA: Enhancing Efficiency in the Oil and Gas Industry Efficient management of pipeline pipe inventory and inspection tracking is crucial for the smooth operation of the oil and gas industry. Introducing PipeDNA, a state-of-the-art cloud-based platform designed to streamline the management of pipe and tube throughout the entire supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage pipeline pipe inventory, increase visibility, and optimize inspection processes. Comprehensive Inventory and Tracking: PipeDNA provides a comprehensive inventory management and tracking system for pipelines, enabling stakeholders to have a real-time view of their pipeline assets. From monitoring utilization and activity to analyzing trends, the platform equips stakeholders with valuable insights to make informed decisions about their pipeline pipe inventory. With enhanced visibility, stakeholders can optimize inventory levels, minimize downtime, and maximize resource utilization. Efficient Logistics Management: Managing the logistics of pipelines can be complex, but PipeDNA simplifies the process by offering robust logistics management features. Stakeholders can efficiently handle shipments, track the status of pipeline pipe in transit, and streamline documentation processes. Additionally, the platform facilitates pipe bundling, ensuring efficient grouping and transportation of pipeline pipe, leading to cost savings and improved operational efficiency. Streamlined Inspection Management: PipeDNA's inspection management capabilities extend to pipelines, allowing stakeholders to effectively manage inspection jobs across multiple sites. The platform enables seamless coordination, tracking of job statuses, and management of inspection profiles. By centralizing inspection data and streamlining workflows, PipeDNA optimizes the inspection process, ensuring compliance with industry standards and mitigating risks associated with pipeline integrity. Enhanced Identification and Traceability: PipeDNA's identification and traceability features enable quick and reliable identification of pipeline pipe, providing comprehensive details, activity history, and traceability documentation. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, facilitating easy tracking and identification of individual pipelines. By enhancing identification and traceability, PipeDNA strengthens quality control measures, streamlines recalls if necessary, and supports compliance with industry regulations. Seamless Integration of Manufacturing Data: PipeDNA seamlessly integrates manufacturing data into its platform, eliminating the need for manual data entry and reducing the risk of human errors. This integration ensures that pipeline-related data, including manufacturing details, is readily available within the system. By automating the transfer of manufacturing data, PipeDNA enables stakeholders to maintain accurate and reliable records, facilitating efficient pipeline pipe management and data-driven decision-making. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's popular and emerging technologies to optimize pipeline pipe inventory and inspection tracking. The platform supports barcoding and labeling systems, integrating popular barcode standards such as UPC, EAN, and QR codes. Additionally, PipeDNA is RFID ready, enabling stakeholders to seamlessly integrate RFID technologies such as labels and asset tags for efficient tracking and management of pipelines. Furthermore, the platform supports IoT data integrations using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced pipeline pipe management processes. PipeDNA revolutionizes pipeline pipe inventory and inspection tracking in the oil and gas industry, providing stakeholders with a powerful cloud-based solution. By offering comprehensive inventory and tracking capabilities, efficient logistics management, streamlined inspection processes, enhanced identification and traceability, and seamless integration of manufacturing data, PipeDNA empowers stakeholders to maximize efficiency and productivity. Embrace PipeDNA and experience the benefits of improved pipeline pipe management, increased visibility, and optimized operations in the oil and gas supply chain.

Service

Currently in Use

Service

New

ASME

Air Freight

Casing Tracking and Management

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

Streamline Casing Tracking and Management with PipeDNA: Maximizing Efficiency in the Oil and Gas Industry Effective casing tracking and management are essential for ensuring seamless operations in the oil and gas industry. Introducing PipeDNA, a cutting-edge cloud-based platform designed to manage pipe and tube throughout the entire supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively track and manage casing, enhancing visibility, productivity, and operational efficiency. Comprehensive Inventory and Tracking: PipeDNA provides full inventory management and tracking capabilities for casing, enabling stakeholders to have a real-time view of their casing assets. From tracking utilization and activity to identifying trends, the platform equips stakeholders with the tools they need to make informed decisions about their casing inventory. With enhanced visibility, stakeholders can optimize their inventory levels, minimize downtime, and maximize resource utilization. Efficient Logistics Management: Managing casing logistics can be complex, but PipeDNA simplifies the process by offering comprehensive logistics management features. Stakeholders can efficiently handle shipments, track the status of casing in transit, and streamline documentation processes. Additionally, the platform facilitates pipe bundling, ensuring the efficient grouping and transportation of casings, which leads to cost savings and improved operational efficiency. Streamlined Inspection Management: PipeDNA's inspection management capabilities extend to casing, enabling stakeholders to efficiently manage inspection jobs across multiple sites. The platform allows for seamless coordination, tracking of job statuses, and management of inspection profiles. By centralizing inspection data and streamlining workflows, PipeDNA optimizes the inspection process, ensuring compliance with industry standards and mitigating risks associated with faulty casings. Automated Tally Operations: Tallying casing is a critical task that can be time-consuming and prone to errors. PipeDNA simplifies and automates tally operations, allowing stakeholders to create and manage tally jobs within the platform. By automating tally workflows, the platform minimizes manual intervention, reduces errors, and saves valuable time. Stakeholders can confidently rely on accurate tallies, enhancing efficiency and accuracy throughout their casing management processes. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide quick and reliable identification of casing, along with comprehensive details, activity history, and traceability documentation. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, enabling stakeholders to easily track and identify individual casings. By enhancing identification and traceability, PipeDNA strengthens quality control measures, streamlines recalls if necessary, and supports compliance with industry regulations. Seamless Integration of Manufacturing Data: PipeDNA seamlessly integrates manufacturing data into its platform, eliminating the need for manual data entry and reducing the risk of human errors. This integration ensures that casing-related data, including manufacturing details, is readily available within the system. By automating the transfer of manufacturing data, PipeDNA enables stakeholders to maintain accurate and reliable records, facilitating efficient casing management and data-driven decision-making. Leveraging Emerging Technologies: PipeDNA leverages today's emerging technologies to optimize casing tracking and management. The platform supports barcoding and labeling systems, integrating popular barcode standards such as UPC, EAN, and QR codes. Additionally, PipeDNA is RFID ready, enabling stakeholders to integrate RFID technologies such as labels and asset tags for seamless tracking and management of casings. Furthermore, the platform supports IoT data integrations using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced casing management processes. PipeDNA revolutionizes casing tracking and management in the oil and gas industry, providing stakeholders with a powerful cloud-based solution. By offering comprehensive inventory and tracking capabilities, efficient logistics management, streamlined inspection processes, automated tally operations, enhanced identification and traceability, and seamless integration of manufacturing data, PipeDNA empowers stakeholders to maximize efficiency and productivity. Embrace PipeDNA and elevate your casing tracking and management to new levels of effectiveness, enabling seamless operations throughout the oil and gas supply chain.

Service

Currently in Use

Service

New

API

Air Freight

Tubular Manufacturing Traceability

PipeDNA is a cloud-based pipe management solution![]() PipeDNA in Houston

PipeDNA in Houston

Enhancing Tubular Manufacturing Traceability with PipeDNA: Ensuring Quality and Compliance In the oil and gas industry, maintaining traceability throughout the tubular manufacturing process is crucial for ensuring quality, compliance, and operational efficiency. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage tubular manufacturing traceability, increase visibility, and optimize their operations for enhanced quality control. Comprehensive Inventory Management and Tracking: PipeDNA offers comprehensive inventory management and tracking capabilities for tubular products, enabling stakeholders to have full visibility into their manufacturing processes. From raw materials to finished products, PipeDNA allows for seamless tracking of each component, ensuring accurate inventory control, reducing waste, and optimizing production planning. Gain insights into utilization, activity, and trends, empowering stakeholders to make data-driven decisions and streamline their manufacturing operations. Streamlined Logistics Management: PipeDNA simplifies logistics management by providing stakeholders with a centralized platform to manage shipments, track status, and document crucial information. Whether it's inbound or outbound logistics, PipeDNA ensures seamless coordination and real-time visibility into the movement of tubular products. The platform also facilitates pipe bundling, allowing stakeholders to optimize transportation and storage, reducing costs and improving overall efficiency. Efficient Inspection Management: With PipeDNA's inspection management feature, stakeholders can effectively manage inspection jobs throughout the tubular manufacturing process. From initial inspections of raw materials to final product inspections, PipeDNA enables tracking and monitoring of job status across multiple sites. By streamlining inspection profiles and documentation, stakeholders can ensure compliance with quality standards, reduce errors, and maintain consistent product quality. Automated Tally Operations: PipeDNA simplifies and automates the tallying process during tubular manufacturing. Stakeholders can create and manage tally operations within the platform, eliminating manual calculations and reducing the risk of errors. By automating pipe tally jobs and workflows, PipeDNA saves time, improves accuracy, and enhances overall manufacturing efficiency. Accurate tally operations enable stakeholders to maintain reliable records and ensure traceability throughout the production cycle. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide stakeholders with quick and accurate pipe identification, detailed pipe information, activity history, and traceability documentation. By integrating popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables seamless identification and tracking of each tubular product. This enhanced traceability minimizes the risk of errors, supports efficient recalls if necessary, and ensures compliance with industry regulations. Designed for the Oil and Gas Industry: PipeDNA was designed specifically for stakeholders across drilling, manufacturing, and oilfield services, catering to their unique needs in tubular manufacturing traceability. Whether you are a drilling contractor, oilfield rental company, oilfield and inspection service provider, steel pipe manufacturer, or pipe distribution and storage provider, PipeDNA offers tailored solutions to streamline your tubular manufacturing processes and drive quality and compliance. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's emerging technologies to optimize tubular manufacturing traceability. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, allowing for efficient barcoding and labeling. Furthermore, PipeDNA is RFID ready, supporting the integration of RFID technologies for accurate asset tracking and improved traceability. The platform also enables IoT data integration using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced decision-making during the manufacturing process. PipeDNA revolutionizes tubular manufacturing traceability in the oil and gas industry, providing a smart cloud-based platform that enhances quality control, compliance, and visibility. With its comprehensive inventory management, streamlined logistics operations, efficient inspection management, automated tally operations, and enhanced identification and traceability features, PipeDNA empowers stakeholders to optimize their tubular manufacturing processes, minimize errors, and ensure compliance with industry standards. Leverage the power of PipeDNA and take your tubular manufacturing traceability to new heights of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

![]() PipeDNA in Houston

PipeDNA in Houston

Enhancing Tubular Inspection Management with PipeDNA: Streamlining Quality Assurance in the Oil and Gas Industry In the oil and gas industry, ensuring the quality and integrity of tubular products is of paramount importance. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to effectively manage and streamline tubular inspection processes, enabling enhanced quality assurance and compliance. Efficient Management of Inspection Jobs: PipeDNA provides a comprehensive solution for managing inspection jobs across multiple sites. Stakeholders can easily create and track inspection jobs, monitor their status, and manage inspection profiles within the platform. This streamlined approach eliminates manual and time-consuming processes, ensuring efficient coordination and effective allocation of inspection resources. Real-time Job Status and Reporting: With PipeDNA, stakeholders can access real-time updates on the status of inspection jobs. The platform enables instant communication and collaboration between inspectors, supervisors, and other relevant parties involved in the inspection process. By providing a centralized hub for reporting and documentation, PipeDNA enhances transparency and allows for swift decision-making based on accurate and up-to-date information. Tailored Inspection Profiles: PipeDNA allows stakeholders to create and manage inspection profiles specific to their tubular products. Customizable inspection profiles enable stakeholders to define the required tests, measurements, and criteria for each type of tubular product. By tailoring inspection profiles to their unique needs, stakeholders can ensure adherence to industry standards and regulatory requirements, ultimately guaranteeing the quality and safety of their tubular assets. Seamless Integration of Inspection Data: PipeDNA offers seamless integration of inspection data, eliminating the need for manual data entry and reducing the risk of human errors. The platform allows for the integration of manufacturing data, ensuring that inspection results are directly linked to the production process. By automating the transfer of data, PipeDNA enables stakeholders to maintain accurate and reliable records, enhancing traceability and facilitating data-driven decision-making. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide stakeholders with quick and accurate pipe identification, detailed pipe information, activity history, and traceability documentation. By integrating popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables seamless identification and tracking of each tubular product. This enhanced traceability minimizes the risk of errors, supports efficient recalls if necessary, and ensures compliance with industry regulations. Leveraging Emerging Technologies: PipeDNA leverages today's emerging technologies to optimize tubular inspection management. The platform supports barcoding and labeling systems, integrating popular barcode standards for efficient identification and tracking. PipeDNA is RFID ready, allowing for integration with RFID technologies such as labels and asset tags, further enhancing asset tracking and traceability. Additionally, PipeDNA supports IoT data integrations using the MQTT standard, enabling fast and reliable sensor data integration for enhanced inspection processes. PipeDNA revolutionizes tubular inspection management in the oil and gas industry, providing a smart cloud-based platform that streamlines quality assurance processes. By offering efficient management of inspection jobs, real-time status updates, tailored inspection profiles, seamless data integration, and enhanced identification and traceability, PipeDNA empowers stakeholders to ensure the highest level of quality and compliance in their tubular assets. Embrace PipeDNA and elevate your tubular inspection management to new levels of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

Streamline Drill Pipe Management with PipeDNA: Enhancing Efficiency and Visibility on the Drilling Rig Efficient management of drill pipe is a critical factor in ensuring smooth drilling operations in the oil and gas industry. Introducing PipeDNA, a smart new platform designed to revolutionize the way drill pipe is managed on the drilling rig. With its cloud-based solution and powerful features, PipeDNA empowers drilling contractors, oilfield rental companies, and oilfield services providers to proactively manage their drill pipe inventory, increase visibility, and optimize their drilling operations. Full Inventory Management and Tracking: PipeDNA offers a comprehensive set of features that enable drill pipe stakeholders to gain complete control over their inventory. With its inventory management and tracking capabilities, PipeDNA provides real-time information on drill pipe utilization, activity, and trends. This invaluable insight allows drilling contractors to make informed decisions regarding drill pipe allocation, maintenance schedules, and resource optimization. Efficient Logistics Management: Managing logistics operations on the drilling rig can be complex and time-consuming. PipeDNA simplifies this process by offering robust logistics management functionalities. Users can efficiently handle shipments, track the status of drill pipe deliveries, manage documentation, and even bundle pipes for streamlined transportation. With PipeDNA, logistics become a well-coordinated and seamless aspect of drill pipe management, saving time and resources. Streamlined Inspection Management: Inspection is crucial for ensuring the integrity and safety of drill pipe. PipeDNA's inspection management feature enables users to efficiently manage inspection jobs across multiple sites, track job statuses, and maintain inspection profiles. This capability ensures that inspections are conducted in a timely manner, minimizing downtime and optimizing drilling operations. Automated Tally Operations: Pipe tallying is a time-consuming task prone to human errors when done manually. PipeDNA simplifies tally operations by providing users with the ability to create and manage tally operations. Automated workflows streamline the tallying process, reducing errors and saving valuable time. By automating tally operations, PipeDNA allows drill pipe stakeholders to focus on more critical aspects of their drilling operations. Enhanced Identification and Traceability: Quick and accurate identification of drill pipe assets is crucial for efficient drilling operations. PipeDNA offers a robust identification and traceability system that provides users with comprehensive drill pipe details, activity history, and traceability documentation. With PipeDNA, drill pipe stakeholders can quickly locate and track specific pipes, ensuring smooth operations and minimizing the risk of errors. Support for Various Drill Pipe Types: PipeDNA's innovative technology is designed to accommodate various types of drill pipe, providing flexibility and adaptability. The platform supports the management of new and premium drill pipe, conventional and spiral HWDP (Heavy Weight Drill Pipe), landing strings, and drilling risers. Whether it's EUE or NUE tubing, workover strings, slick or spiral drill collars, or API 6A flanges, PipeDNA can efficiently manage a wide range of drill pipe and tube types, catering to the diverse needs of the drilling industry. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's popular and emerging technologies to streamline workflows and digitize drill pipe management processes. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, facilitating seamless identification and tracking. PipeDNA is also RFID-ready, providing integration support for RFID technologies, including labels and asset tags. Furthermore, the platform supports IoT data integration using the MQTT standard, allowing fast and efficient integration of sensor data. PipeDNA is transforming drill pipe management on the drilling rig, offering a cloud-based platform that enhances efficiency, increases visibility, and optimizes drilling operations. With its powerful features, seamless integrations, and innovative technology, PipeDNA empowers drilling contractors, rental companies, and oilfield services providers to proactively manage their drill pipe inventory, reduce costs, and improve overall performance. Streamline your drill pipe management processes with PipeDNA and elevate your drilling operations to new heights of productivity and success.

Claims Management and Forensics Management Platform (for construction projects)

KEY360![]() KEY360 Inc in New York, NY

KEY360 Inc in New York, NY

KEY360 Inc offers a single integrated Business Management Platform comprising Business Intelligence, Project Management, Big Data & Analytics, ERP, Behaviour and Strategy Modification. - Over 140 Business and Project Management Systems on one platform available - Unique and extremely effective workflow engine - Remarkable “BIG DATA” and bulk transaction capability - Integrated Real Time reporting and dashboarding - Multi-company platform allows all project users to integrate seamlessly KEY Differentiators: - KEY360 Provides an exceptional opportunity for your organisation to attract new clients and build long terms relationships. - KEY360 is a Microsoft Gold Partner and Approved Microsoft Co-Sell Partner and can be purchased directly from the below online marketplaces: - Microsoft AppSource: KEY360 Capital Management Projects - Azure Marketplace: KEY360 Capital Management Projects - KEY360 is reputedly the most comprehensive and versatile Capital Project Management, Business Digitalization & Business Optimization solution available.

Service

In Stock

Service

New

ISO

![]() CWB National Leasing in Winnipeg

CWB National Leasing in Winnipeg